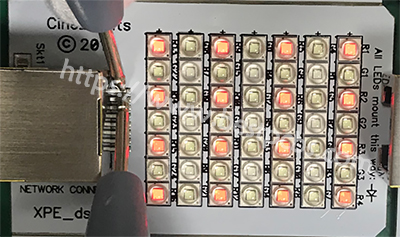

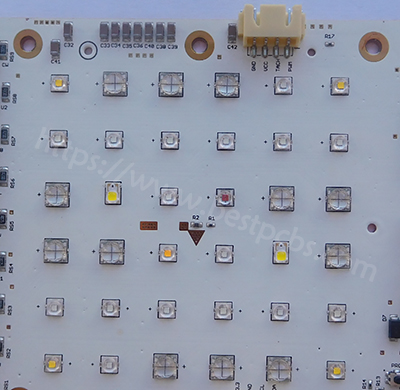

Compared to conventional LED, high-power LED consume more electricity and require higher currents, but the heat generated in the end cannot be dissipated in time through the ordinary FR4 CPB. And there will be some failures when the heat from a LED is not properly removed, the LED’s light output is reduced as well as degradation when the heat remains stagnant in the LED package.

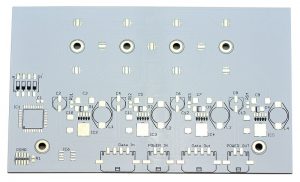

So if the PCB requires fast cooling, it’s better to use a metal base rather than a traditional FR-4 substrate. The typical LED MCPCB┬áis a single circuitry layer copper foil which is bonded to a layer of thermally conductive dielectric material which is bonded to a thicker layer of metal like Aluminium or Copper base, the purpose of a MCPCB is to efficiently remove the heat from all topical IC’s (not just LEDs). Following are the comparison┬ábetween FR4 PCB and┬áMCPCB for your reference.

1. Thermal Dissipation

FR4 has low thermal conductivity, typically around 0.3W/m.K, while MCPCB has higher thermal conductivity, ranging from 1.0-7.0W/m.K. MCPCB transfer heat 8 to 9 times faster than FR4 PCB, the dielectric layer must be very thin to create the shortest path from the heat source to the supporting metal plate, its thickness is normally between 0.003 and 0.006 inches.

As an example, consider that a test conducted on an MCPCB with integrated 1W LED showed how its temperature remained pretty close to the ambient temperature of 25┬░C, while the same power LED mounted on a FR-4 board reached a temperature 12┬░C higher than the ambient one.

2. Better Strength and Stability

Since high power LED chips are usually assembled directly on the PCB, these LEDs can create stability and reliability problems for the circuit. Without adopting the right technique, heat dissipation can hinder the performance of electronic devices that operate at high power. The use of metal PCBs in these applications effectively solves this problem. In addition to ensuring a high durability, aluminum is very light, and adds strength and resilience to the printed circuit board without causing an increase in weight.

3. Dimensional Stability

The size of a metallic printed circuit board remain more stable, as environmental conditions vary, than that of a PCB made with traditional materials, such as FR-4. Subjected to a heating process from 30┬░C to about 150┬░C, PCBs with metal layers (such as aluminum) have undergone a very small variation in size, ranging from 2.5% to 3.0%.

If you have other questions about MCPCB, welcome to contact us.