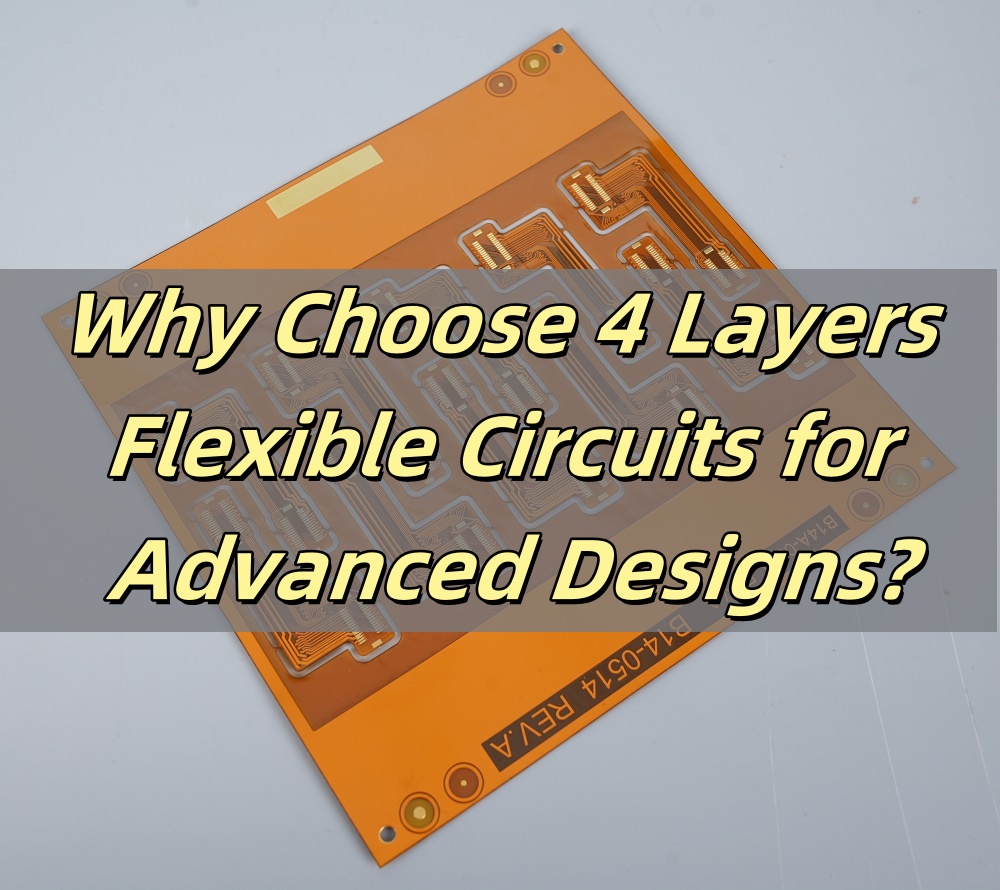

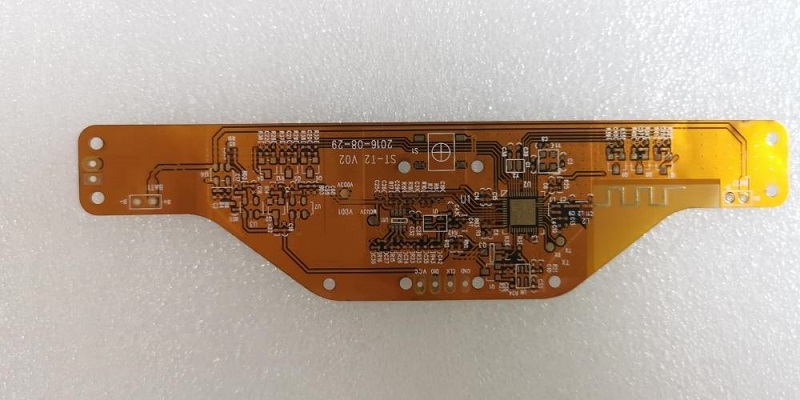

4 layers flexible circuits stand out for their balance of complexity and efficiency. They cater to designs where reliability and space-saving are priorities. Flex PCBs have transformed electronic design, offering unmatched adaptability and compactness. Whether you’re exploring 4 layers flexible circuit samples or planning 4 layer flexible circuit mass production, Best Technology provides solutions tailored to your needs.

How Many Layers Can a Flex PCB Have?

Flex PCBs can have a single layer or up to dozens, depending on the design’s needs. A simple device may only need a single-layer flex PCB. In contrast, advanced gadgets, like smartphones or medical devices, use multiple layers. With up to 20 layers possible in some designs, 4-layer PCBs offer a perfect middle ground for efficiency and functionality.

What Is a 4 Layer PCB Structure?

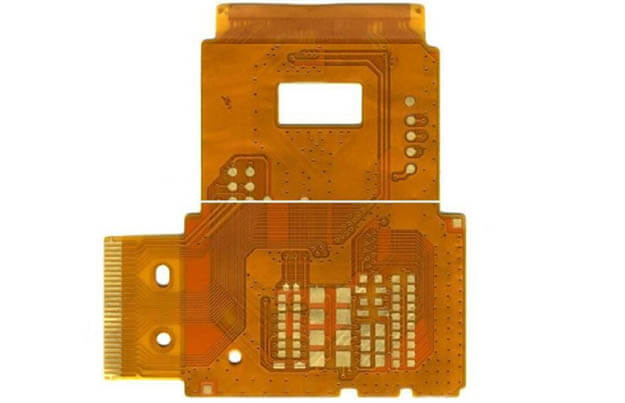

A 4-layer PCB structure includes four conductive layers, separated by insulating material. Typically, the layers consist of two signal layers and two power or ground layers. This structure enhances signal integrity and reduces electromagnetic interference. The flexibility comes from the use of thin, durable materials, allowing for easy bending and folding without compromising functionality.

What Is the Adhesive in Flex PCB?

Adhesives play a critical role in bonding layers in flex PCBs. Polyimide film or similar materials are commonly used for insulation and protection. These adhesives maintain flexibility while ensuring the layers stay intact. High-quality adhesives are crucial for preventing delamination and ensuring durability, especially in 4 layers flexible circuits.

What Is the Maximum Size of Flex PCB?

Flex PCBs can be manufactured in a wide range of sizes, depending on design requirements and application. The maximum size is often determined by the equipment used in production. For 4 layers flexible circuit mass production, the size typically balances the need for compactness with functionality. Larger flex PCBs are ideal for industrial systems, while smaller ones fit wearable devices and medical instruments.

How Thick Is a 4 Layer Flex PCB?

The thickness of a 4-layer flex PCB can range between 0.2 mm to 0.6 mm. This thin profile makes them perfect for compact designs. Variations depend on the materials and the application’s specific needs. The lightweight nature of these PCBs ensures they fit into tight spaces while maintaining durability and performance.

How to Make a 4 Layer PCB?

Creating a 4-layer PCB involves precise layering and etching processes. The steps include:

Design Creation: Using specialized software to map the circuit.

Material Selection: Choosing high-quality substrates and adhesives.

Layer Stacking: Arranging conductive layers with insulating material.

Etching and Lamination: Forming the circuit pattern and bonding layers.

Testing: Ensuring functionality and reliability through rigorous checks.

Experienced manufacturers like Best Technology excel in producing 4 layers flexible circuit with stringent quality standards. If you are interested, just feel free to contact us at sales@bestpcbs.com.

Why Use Flex PCB?

Flex PCBs are highly adaptable, lightweight, and perfect for space-constrained applications. They are resistant to vibrations, making them ideal for automotive, medical, and aerospace industries. Unlike rigid PCBs, they can endure bending and twisting, ensuring longevity even in challenging conditions.

What Are the Benefits of 4 Layer PCB?

A 4-layer PCB provides superior signal integrity due to dedicated power and ground layers. The compact design reduces electromagnetic interference and supports high-speed circuits. ItÔÇÖs perfect for advanced electronics that require reliability, like communication devices and wearables. The balance of complexity and functionality makes it a cost-effective choice for mass production.

4 layers flexible circuits are essential for compact, reliable, and high-performance designs. From reducing weight to improving flexibility, they cater to various industries. Whether you need 4 layers flexible circuit samples or are planning 4 layer flexible circuit mass production, Best Technology is a trusted partner. With advanced capabilities and a commitment to quality, we deliver solutions that meet your needs.

Tags: 4 Layers Flexible Circuits, PCB, pcb design, printed circuit board