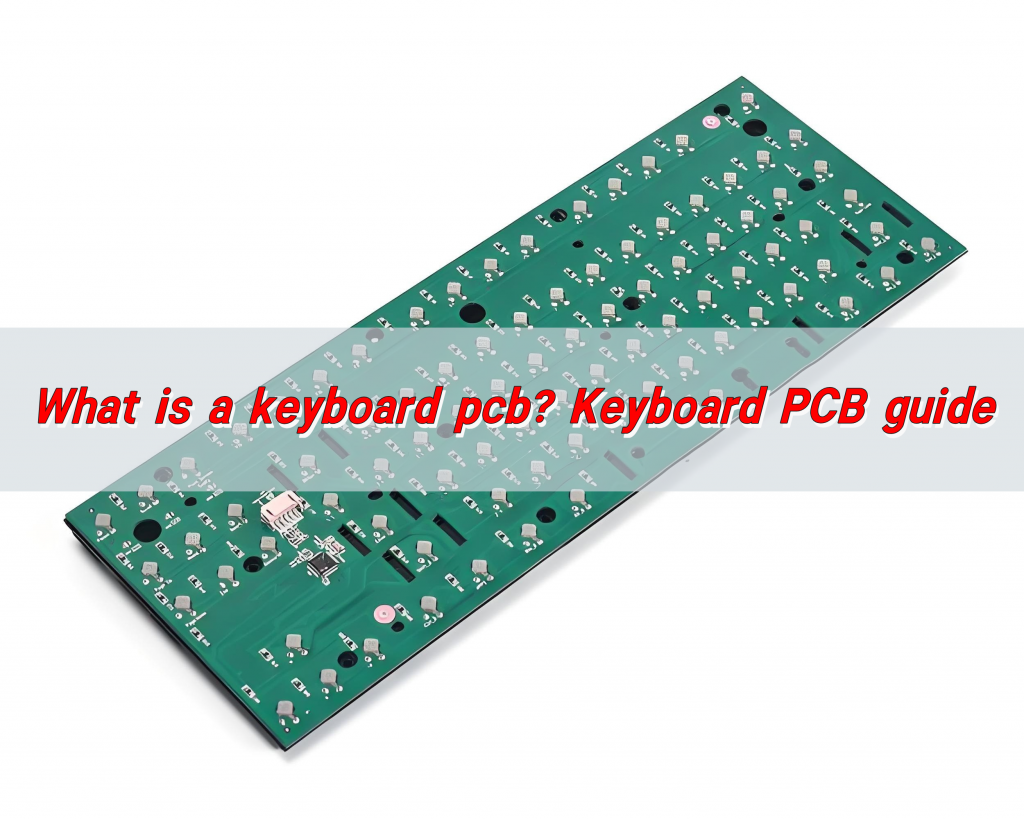

The keyboard PCB is the core component inside the keyboard, responsible for connecting each key and transmitting electrical signals. It contains components such as microcontrollers, diodes, resistors, capacitors, and light-emitting diodes to process key signals and communicate with the computer.

The design and type of the keyboard PCB will affect the feel and performance of the keyboard. Common types include hot-swappable PCB and soldered PCB. Hot-swappable PCB is easy to disassemble and replace, suitable for users who pursue customization, while soldered PCB is more stable and suitable for high-end keyboards.

What is a Keyboard PCB?

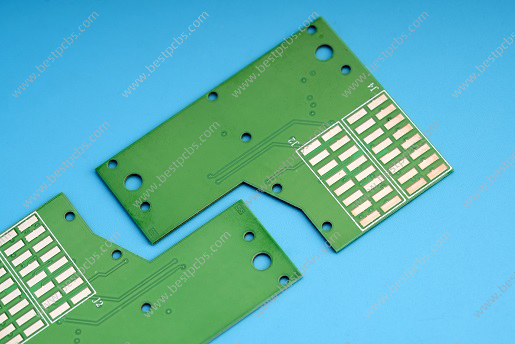

A keyboard PCB (Printed Circuit Board) is a thin board made of fiberglass or other durable materials, with copper traces and electronic components that allow the keyboard to communicate with a computer. It connects all the switches and transfers keypress signals to a controller, which processes the input.

Unlike traditional rubber dome keyboards, mechanical keyboards use a more advanced PCB that supports various switch types, customizable firmware, and advanced features like RGB lighting and macros.

Some keyboards use a hot-swappable PCB, which allows users to change switches without soldering. Others require permanent soldering, making modifications more complex. More advanced versions, such as Hall effect PCBs, rely on magnets instead of physical contact for key activation, offering greater durability and precision.

How to Design a Keyboard PCB?

Designing a keyboard PCB starts with defining the layout. The first step is deciding the number of keys, spacing, and size. Keyboards come in various sizes—full-size, tenkeyless (TKL), 75%, 60%, and even split ergonomic layouts.

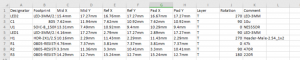

After defining the layout, engineers use software like KiCad, Eagle, or Altium to create schematics. The PCB must include appropriate traces for key signals, diodes for anti-ghosting, and microcontrollers like an Atmel ATmega32U4 or STM32, which processes key inputs.

Engineers must also consider USB connectivity, ensuring reliable power and data transfer. Once the design is complete, the PCB undergoes prototyping to test functionality before mass production.

How to Make a Keyboard PCB?

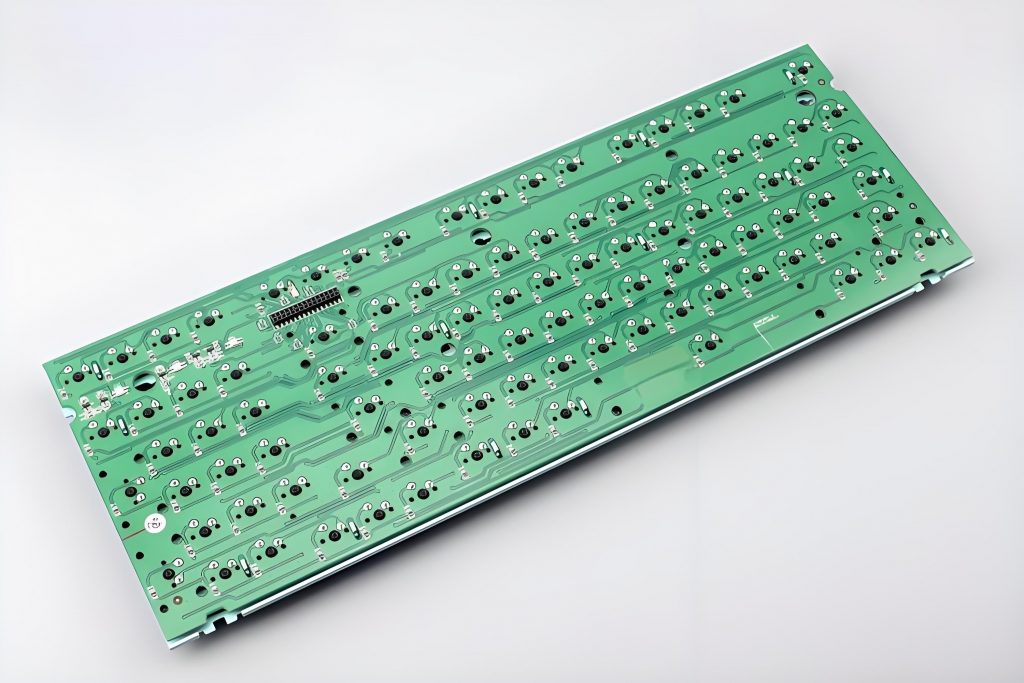

Manufacturers use FR4 for durability. The PCB is manufactured using a layering process where copper is etched to form electrical pathways. Holes are drilled to accommodate switches and components. After etching, a protective solder mask is applied, followed by a silkscreen layer for labeling.

Quality control is essential. Each PCB undergoes electrical testing to check for short circuits or defects. Once approved, it moves to the assembly process, where switches, diodes, resistors, and controllers are mounted onto the board.

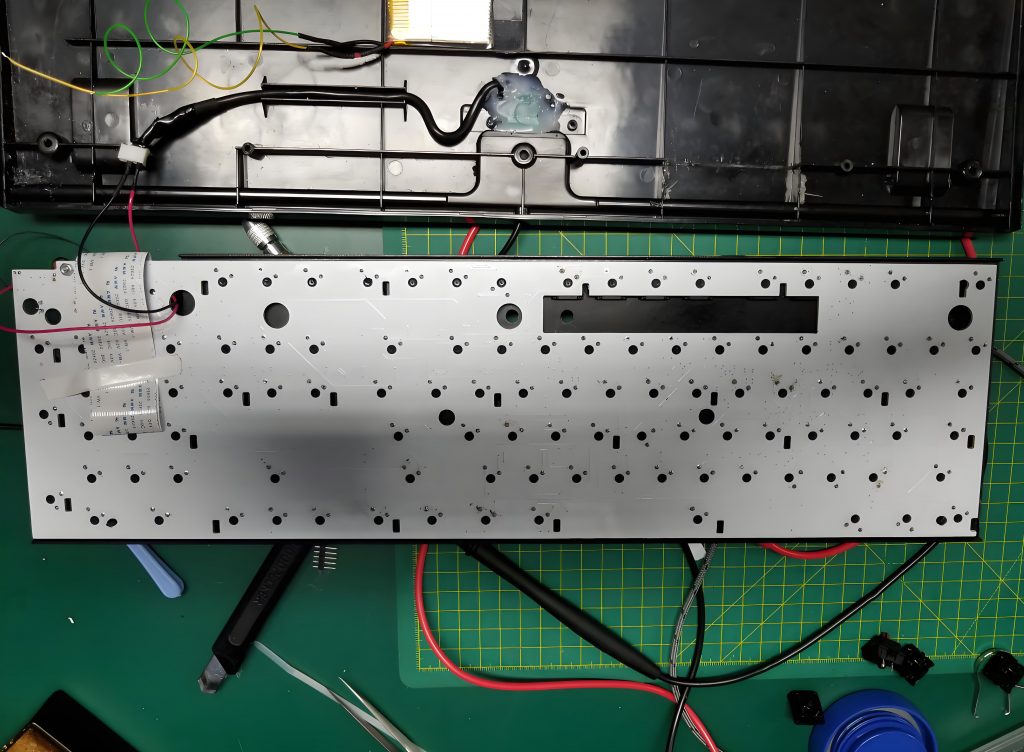

How to Solder a Keyboard PCB?

Soldering a keyboard PCB requires patience. First, switches are placed into the PCB and secured with a plate. Each switch has two metal pins that must be soldered to their corresponding PCB pads. Using a soldering iron, heat is applied to the joint, melting solder to create a strong electrical connection.

Proper soldering techniques prevent cold joints, which can cause inconsistent key response. Lead-free solder is preferred for environmental reasons, but it requires higher temperatures.

Once all switches are soldered, the PCB is connected to a computer for testing. If any keys fail to register, reflowing the solder joint usually solves the issue.

How to Clean a Keyboard PCB?

Dirt and dust can accumulate on a PCB over time, leading to key malfunctions. Cleaning a keyboard PCB is simple. A soft brush, compressed air, or isopropyl alcohol helps remove debris. Avoid using water, as moisture can cause short circuits.

If liquid spills occur, immediate cleaning with alcohol prevents permanent damage. Regular maintenance ensures long-term performance.

What are the Types of Keyboard PCBs?

Keyboards come in different PCB configurations, each catering to specific needs:

- Standard PCBs: Require switches to be soldered in place.

- Hot-Swappable PCBs: Feature socketed switch mounts, allowing easy replacement without soldering.

- Flexible PCBs: Made from polyimide, commonly found in compact or ergonomic keyboards.

- Hall Effect PCBs: Use magnetic fields instead of physical contacts, offering longer lifespan.

What are the Functions of a Keyboard PCB?

A keyboard PCB does more than just register keypresses. It manages power distribution, controls RGB lighting, and enables advanced features like macros and key remapping.

Many PCBs come with built-in support for QMK or VIA firmware, allowing users to program custom shortcuts and layouts.

Another key function is anti-ghosting and n-key rollover (NKRO), ensuring multiple keypresses register simultaneously. Some PCBs also integrate wireless capabilities, enabling Bluetooth connectivity.

How to Make a Keyboard PCB Hot-Swappable?

A hot-swappable keyboard PCB eliminates the need for soldering. Instead of fixed switch mounts, it uses hot-swap sockets that hold the switch pins securely. These sockets are soldered onto the PCB during manufacturing, allowing users to swap switches effortlessly.

Gamers and enthusiasts prefer hot-swappable keyboards because they offer customization without permanent modifications. If a switch malfunctions, replacing it takes seconds. However, these PCBs require careful handling, as frequent swapping can wear out the sockets over time.

Conclusion:

A keyboard PCB is the core of any mechanical or membrane keyboard. It controls everything from key registration to backlighting and custom macros. For high-quality custom keyboard PCBs, contact sales@bestpcbs.com

Tags: keyboard pcb