Fiberglass circuit board is the backbone of today’s electronics. These boards support and connect components in almost every electronic device, from consumer gadgets to industrial control systems. Unlike ordinary materials, fiberglass brings strength and stability. It holds up well under heat, resists moisture, and stays firm under mechanical stress.

What Are Fiberglass Circuit Boards?

A fiberglass circuit board is a type of printed circuit board (PCB) made using a base material reinforced with glass fibers and resin—typically epoxy. This combination results in a strong, heat-resistant, and electrically stable platform used to mount and interconnect electronic components.

Also called printed circuit board fiberglass, these boards dominate the electronics industry thanks to their durability and consistent performance. From mass-produced gadgets to high-end machinery, fiberglass boards provide the structural and electrical backbone that keeps everything working smoothly.

What Are Fiberglass Boards Made Of?

Fiberglass boards are made from fine strands of glass spun into a fabric. This fabric, typically known as glass cloth, is then saturated with epoxy resin. Once hardened, the composite becomes the core insulating layer in a fiberglass circuit board.

The most common material is FR4. It includes:

- Woven E-glass (Electrical-grade glass): Provides electrical insulation and dimensional stability.

- Epoxy resin: Bonds the glass fibers and maintains structure under thermal stress.

- Copper foil: Laminated onto one or both sides to create electrical pathways.

Together, these elements create an electrical fiberglass board that is tough, heat-resistant, and non-conductive at its core.

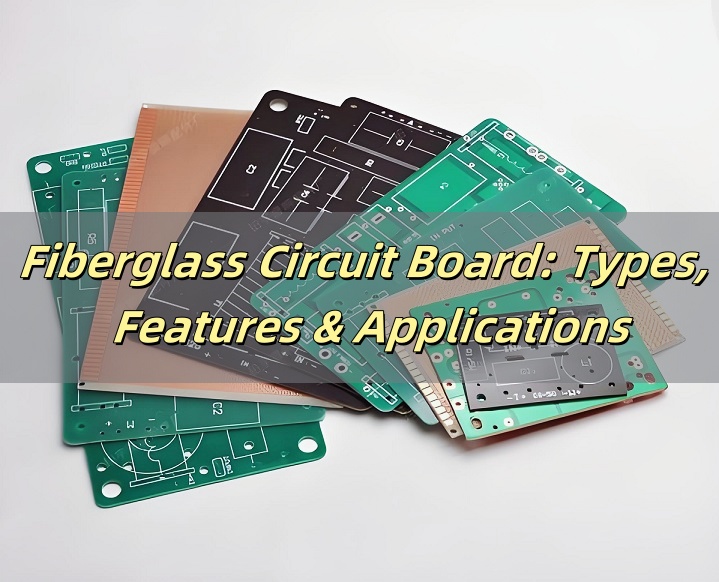

Types of Fiberglass Circuit Boards

Fiberglass circuit boards aren’t one-size-fits-all. They come in multiple variations to meet different design and performance needs. Whether you’re designing a basic remote control or a complex radar module, there’s a fiberglass board fit for the job.

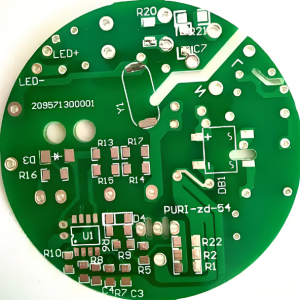

- Single Layer Fiberglass Circuit Board

This is the most basic type. It has copper traces on only one side of the board. It’s often used in low-cost consumer electronics, LED lights, and household appliances. Despite its simplicity, the fiberglass circuit board structure keeps it durable and stable.

- Double Layer Fiberglass Circuit Board

With copper layers on both sides and vias connecting them, this board offers more routing space and better performance. It’s a popular choice for audio equipment, industrial sensors, and power supplies. These boards balance cost with performance and are widely produced by fiberglass circuit board manufacturers worldwide.

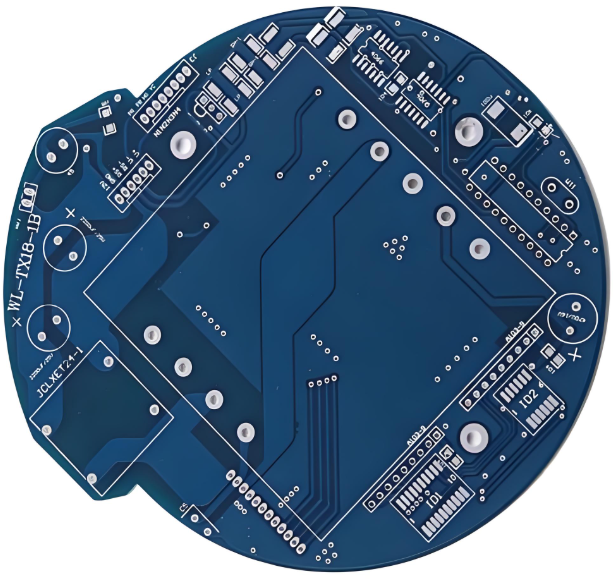

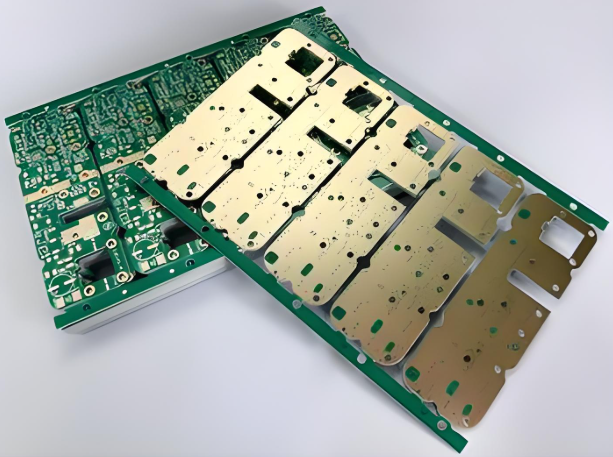

- Multilayer Fiberglass Circuit Board

These contain three or more layers of fiberglass and copper laminated together. They are essential for smartphones, routers, and advanced computing devices. With increased layer count comes better signal control and component density.

- HDI Fiberglass Circuit Board

High-Density Interconnect (HDI) boards pack more functionality into smaller areas. They use microvias, blind vias, and fine lines to boost performance without increasing board size. HDI designs often use printed circuit board fiberglass materials for strength and tight tolerances.

- High Frequency Fiberglass Circuit Board

For RF or microwave applications, standard fiberglass isn’t always enough. Specialized fiberglass composites with low dielectric loss are used. These boards are perfect for radar systems, antennas, and satellite communication.

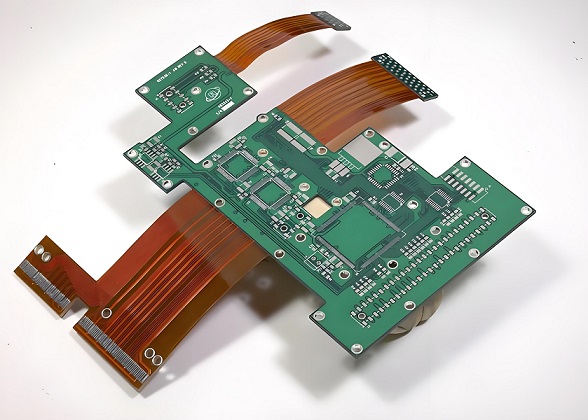

- Rigid-Flexible Fiberglass Circuit Board

Combining rigid fiberglass sections with flexible polyimide layers, these hybrid boards offer both structural support and flexibility. They’re widely used in wearables, military electronics, and compact medical devices.

Features of Using Fiberglass Circuit Board

Fiberglass circuit boards offer several unmatched advantages. These features help explain why they’re so common in nearly every electronic product.

- Thermal Stability: Fiberglass holds up well under heat. It won’t warp or delaminate under typical operating conditions.

- Dimensional Stability: Even in humid or fluctuating environments, the board keeps its shape.

- Electrical Insulation: The glass fibers prevent current leakage and minimize signal loss.

- Mechanical Strength: These boards don’t crack easily. They can take a beating during assembly or usage.

- Low Fiberglass Board Price: Compared to ceramics or PTFE substrates, fiberglass board price is much lower—without major performance tradeoffs.

Why Is Fiberglass Used in Motherboards?

Motherboards are the nerve center of any computing device. They require a substrate that’s flat, stable, and electrically inert. Fiberglass checks all those boxes. Its woven glass core resists bending and warping over time, ensuring that pins, sockets, and solder joints stay aligned. It also helps dissipate heat generated by processors and other high-power components.

Motherboards also demand multi-layered structures. Only multilayer fiberglass circuit boards can deliver the routing density needed for complex connections between CPU, RAM, GPU, and other modules. That’s why fiberglass remains the default material for virtually all desktop and laptop motherboards.

What Is Fiberglass Board Used For?

Beyond motherboards, electrical fiberglass boards are everywhere:

- Consumer Electronics: Smartphones, TVs, game consoles.

- Automotive Systems: Engine controls, infotainment, safety modules.

- Industrial automation: Robotics, factory controls, and power distribution.

- Healthcare equipment: Monitors, diagnostic tools, and imaging devices.

- Telecom Infrastructure: Routers, switches, and antennas.

- Telecommunication devices: Routers, modems, and base stations.

- LED Lighting: Strip lights, bulb circuits, streetlamps.

- Aerospace Systems: Flight controls, navigation, radar electronics.

Thanks to their adaptability and performance, fiberglass boards can be customized for nearly any electrical task. This is why fiberglass circuit board manufacturers remain in high demand globally.

Why Is Fiberglass Hazardous?

Though highly useful, fiberglass isn’t without precautions. During manufacturing, cutting or sanding fiberglass can release microscopic glass particles. These can irritate the skin, eyes, and respiratory system. That’s why workers must wear protective gear in production settings.

However, once the board is sealed and installed, it poses minimal risk. Finished electrical fiberglass boards are stable, safe, and inert under normal use conditions. They do not emit toxins or degrade during product life.

Is Glass Fiber the Same as Fiberglass?

Technically, yes—glass fiber and fiberglass refer to the same material. “Glass fiber” usually describes the raw filament or strands. “Fiberglass” refers to the composite made from glass fibers and resin.

In PCB manufacturing, the terms are often used interchangeably. Whether you say printed circuit board fiberglass or glass fiber PCB, the meaning remains consistent: a reliable, heat-resistant circuit platform. While the terms are related, in practice, fiberglass is the final product used in PCBs, not just the raw glass fiber.

FAQs

Q1: Is fiberglass better than FR2 in circuit boards?

Yes. Fiberglass (FR4) offers higher strength, better insulation, and improved heat tolerance compared to FR2 paper-based boards.

Q2: How much does a fiberglass board cost?

The fiberglass board price varies by layer count, size, and copper thickness. Single-layer boards may cost less than $1 per piece, while multilayer HDI boards are higher.

Q3: Can fiberglass circuit boards handle high power?

Yes. With proper copper thickness and thermal management, fiberglass PCBs handle moderate to high power loads reliably.

Q4: Are fiberglass boards environmentally friendly?

Most are ROHS-compliant. However, disposal must be handled properly due to the epoxy content.

Q5: Who are top fiberglass circuit board manufacturers?

Top producers include Best Technology, TTM Technologies, and PCBWay. Look for ISO-certified factories with full in-house fabrication.

Whether you’re building a simple LED board or a complex communication device, printed circuit board fiberglass options are there to support your design.

Looking for a trustworthy partner to supply high-quality fiberglass PCBs? Best Technology has more than 18 years of experience manufacturing standard and custom circuit boards, including single to multilayer designs, HDI, and high-frequency variants. Our in-house production facilities are ISO9001, IATF16949, AS9100D and UL certified, ensuring that every board meets global quality standards. We pride ourselves on delivering fast lead times, customized solutions, and exceptional technical support that help our clients stay ahead in an ever-evolving market.

Tags: Electrical fiberglass board, Fiberglass board price, Printed circuit board fiberglass