How does a breadboard work? Breadboard allow users to quickly build and test circuits without soldering through their unique structural design. It usually consists of a plastic board with many small holes on it, and these small holes are connected to metal pieces inside. By inserting electronic components into these holes, electrical connections can be made between components, and circuits can be quickly built and tested.

What is a Breadboard?

A breadboard is a reusable platform for building temporary electronic circuits. It consists of a rectangular plastic board with a grid of small holes, into which components such as resistors, capacitors, transistors, and integrated circuits (ICs) can be inserted. These holes are connected internally by thin metal strips that create an electrical path without requiring soldering.

The biggest advantage of a breadboard is its flexibility. Unlike traditional PCBs, where components must be soldered, a breadboard allows for quick modifications. This makes it perfect for testing new circuit ideas, troubleshooting problems, and making iterative design changes without permanently fixing components in place.

What’s Inside a Breadboard?

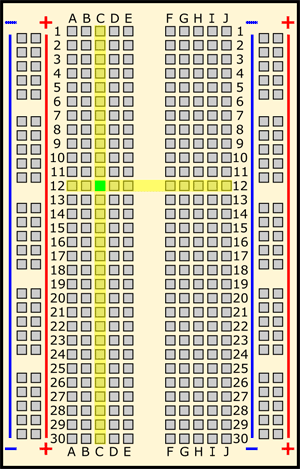

Though a breadboard appears simple on the outside, its internal structure is what makes it work efficiently. Underneath the surface, it has rows of conductive metal strips that connect certain holes together.

A standard breadboard is divided into three main sections:

- Power Rails: These are the long horizontal strips on both sides of the board, usually marked with red and blue lines. They are used to distribute power (positive and negative voltage) across the board, making circuit connections easier.

- Terminal Strips: These are the main working area where most of the components are placed. Each row of five holes is electrically connected, allowing for easy placement and wiring of circuit elements.

- Central Divider: The middle gap on a breadboard separates the two halves, which is especially useful for placing integrated circuits (ICs). This ensures that each pin of the IC remains isolated from the others unless explicitly connected with wires.

How Does Current Flow in a Breadboard?

When a component is inserted into a row, it automatically becomes connected to other components within the same row. However, the middle divider prevents direct connections across the board, requiring jumper wires for cross-board connections.

The power rails run vertically, meaning that any component connected to the power strip has access to the same voltage supply. By carefully arranging components and jumper wires, circuits can be created and modified without the need for soldering or permanent wiring.

How does a breadboard work?

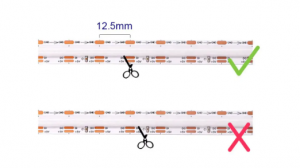

The working principle of breadboard is based on the clever layout of internal metal strips. The core of the breadboard is that the circuit can be quickly built without soldering. The jacks on the board are connected by metal strips arranged in parallel at the bottom. Every five holes form a conductive path. When the component pins or wires are inserted into the same group of holes, they can be turned on.

The groove in the center divides the panel into two parts, which are used to insert dual in-line integrated circuits (DIP) to ensure that the pins will not short-circuit. The vertical power rails (marked with “+” and “-“) on both sides provide unified power supply for the entire circuit. The holes on the same side are connected by internal metal strips. When in use, the power rails need to be connected with wires to distribute power.

When building a circuit, it is necessary to plan the position of the components according to the circuit diagram, insert the pins into the corresponding jacks and pay attention to the polarity. Jumpers are used to connect different groups of holes. It is necessary to avoid jumping integrated circuits or overlapping wires. When experimenting, the power supply should be disconnected before operating the components to prevent short circuits.

Breadboards are divided into solderless, single-sided and combination types. The solderless type is portable and suitable for simple experiments, while the combination type supports complex projects but is larger in size. When using, please pay attention to the thickness of the component pins (no more than 0.8mm). It is recommended to connect the wires horizontally and vertically to facilitate testing.

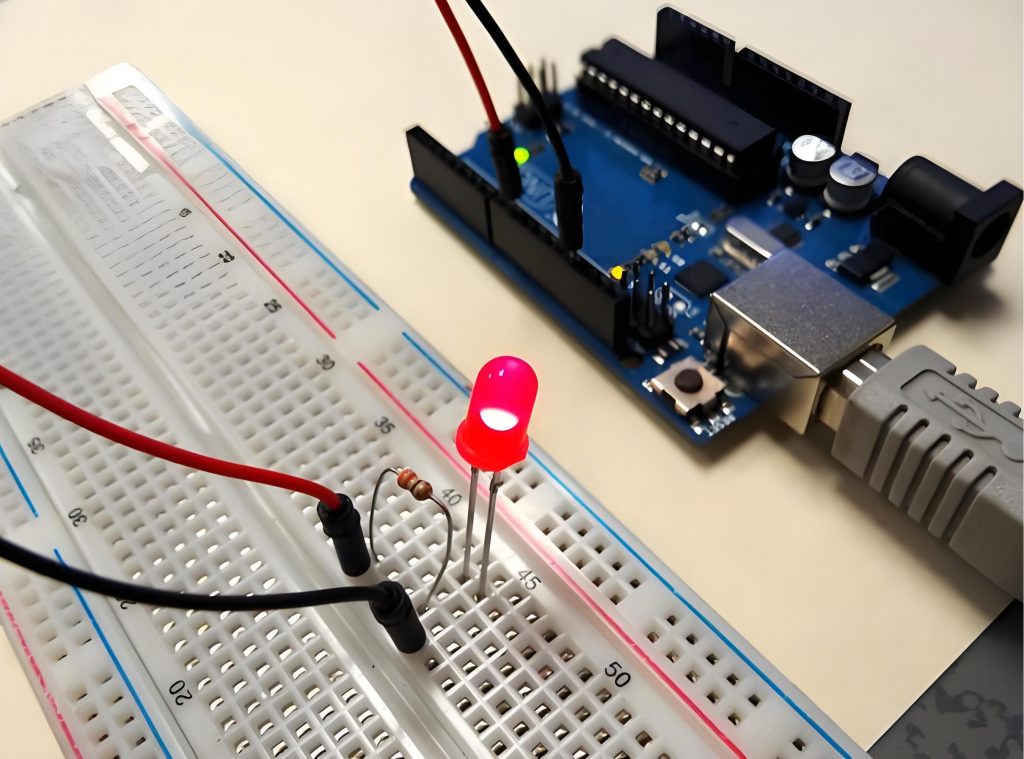

How to Use a Breadboard?

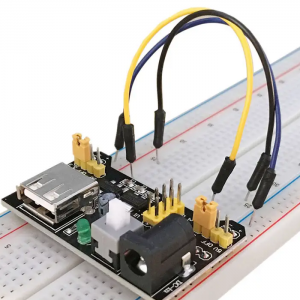

To begin, you first need a power source, such as a battery or a power adapter. The positive and negative terminals should be connected to the power rails to ensure consistent voltage distribution.

Next, components such as resistors, LEDs, transistors, and capacitors can be placed in the terminal strips. Each component should be positioned in a way that allows proper current flow. To complete the connections, jumper wires are inserted to link different components together, forming a functional circuit.

Once the circuit is assembled, the power supply is activated, allowing the circuit to operate. This flexibility makes breadboards invaluable for rapid prototyping and troubleshooting.

What Are the Lines on a Breadboard?

The lines on the breadboard indicate its internal connections. These markings make it easier to plan the layout of the circuit.

- Power Rail Lines (Red and Blue): The red line represents the positive voltage, while the blue line represents the negative or ground connection.

- Horizontal Row Markings: These indicate that all the holes within a row are electrically connected.

- Central Divider: This is a key feature that separates two halves of the breadboard, preventing direct electrical connections between them unless linked with wires.

How Much Current Can a Breadboard Handle?

Breadboards are not designed for high-current applications. Most standard breadboards can safely handle around 0.5A to 1A of current. Going beyond this limit can cause overheating, loose connections, or even damage the breadboard’s internal metal strips.

For high-power circuits, using a PCB or soldered perf board is recommended to ensure durability and efficiency.

What Are the Types of Breadboards?

Breadboards come in different types, each suited for specific applications. The most common types include:

- Solderless Breadboards: These are the most widely used, featuring removable and reusable connections, making them ideal for prototyping.

- Solderable Breadboards: These provide a more permanent solution by allowing components to be soldered onto them after prototyping is complete.

- Stripboards (Veroboards): These contain continuous copper tracks that can be cut as needed to customize circuit layouts.

- Mini Breadboards: These are compact and perfect for small-scale circuits or portable electronic projects.

What Are the Disadvantages of a Breadboard?

Despite their versatility, breadboards do have some limitations:

- Limited Current Capacity: They are not suitable for high-power applications.

- Unreliable for High Frequencies: The internal resistance and capacitance can affect signals above 10MHz, making them unsuitable for RF applications.

- Loose Connections: Components and wires can become unstable, leading to intermittent circuit failures.

For more permanent and high-performance applications, PCBs are the best choice.

What is the Frequency Limit of a Breadboard?

Breadboards are best suited for low-frequency circuits. Due to their internal capacitance and resistance, they typically function reliably below 10MHz. Above this range, signal integrity issues arise, causing unwanted noise, interference, and potential malfunctions.

For high-frequency applications, custom PCBs or RF-specific boards are the recommended alternatives.

Conclusion:

A breadboard is a must-have for anyone working with electronics. It allows fast, flexible, and cost-effective circuit building.

Their reusability, affordability, and ease of use make them the perfect choice for prototyping. However, for high-current or high-frequency applications, PCBs are the better alternative. For custom PCB solutions, contact sales@bestpcbs.com

Tags: breadboard, breadboard pcb, breadboard work, pcb breadboard