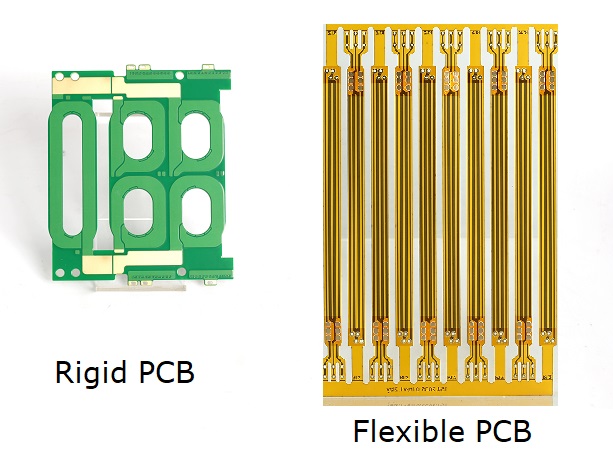

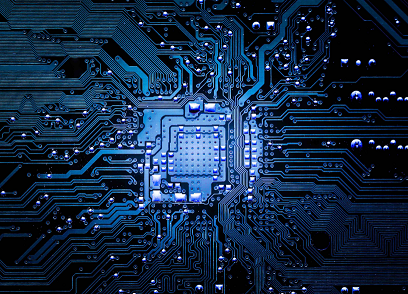

Best Technology Circuit is one of a leading PCB manufacturers in USA. Our products cover a wide range of solutions, from standard FR4 PCBs and multi-layer PCBs to advanced options like metal-based PCBs (MCPCBs), ceramic PCBs, flexible and rigid-flex PCBs, and high-frequency PCBs. As a leading PCB fabrication manufacturer, we are equipped with a monthly production capacity of 260,000 square feet (28,900 square meters), allowing us to complete over 1,000 different boards every month. Additionally, we understand the need for speed in todayâs market, which is why we offer expedited services, ensuring urgent boards can be shipped out within 24 hours to meet tight deadlines.

As a custom manufacturer, we believe that continuous growth is essential to success. Thatâs why we prioritize significant investments in research and development, staying ahead of the latest trends in the PCB industry. Our commitment to quality and customer satisfaction drives us to build lasting relationships and offer personalized support and solutions. While many PCB manufacturers in USA focus solely on production, we go beyond by providing tailored services that address the unique needs of each client. This approach has helped us stand out among PCB fabrication manufacturers, delivering reliable, high-performance boards to meet diverse industry demands. Whether you’re looking for specialized designs or quick turnaround times, we are here to support your goals.

What is PCB Manufacturing

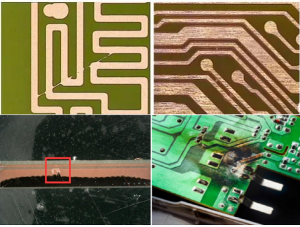

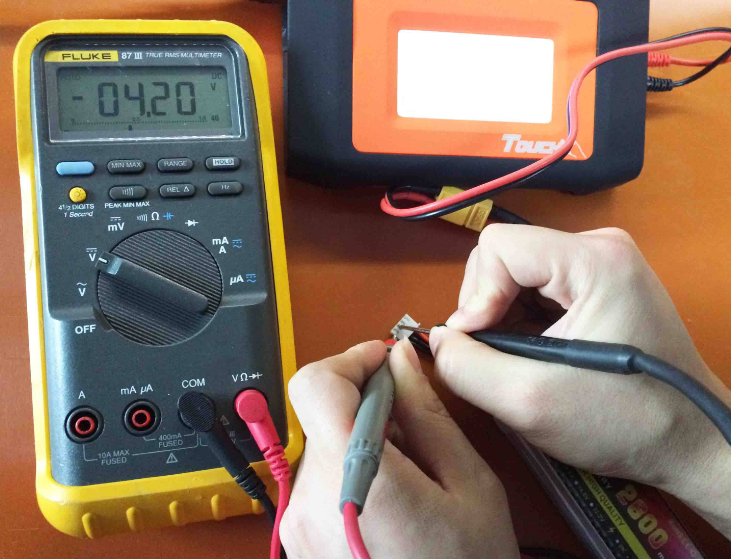

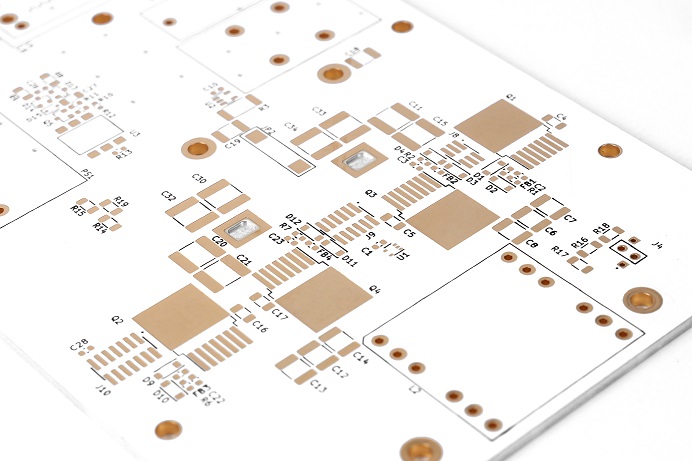

What is PCB Manufacturing?PCB manufacturing is the process of converting circuit design into actual printed circuit boards (PCBs) through a series of processes. PCBs are boards used to connect and support electronic components in electronic devices. They are mainly composed of insulating materials and conductive materials. They connect various electronic components to each other through conductive paths, power supply, and signal transmission.

How is a PCB Manufactured

How is PCB manufactured? First, the PCB circuit diagram is designed, then the film is made, coated, exposed, developed, etched, laminated, drilled, electroplated, and finally surface treated to manufacture the PCB.

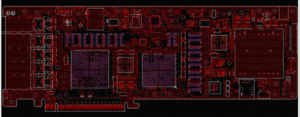

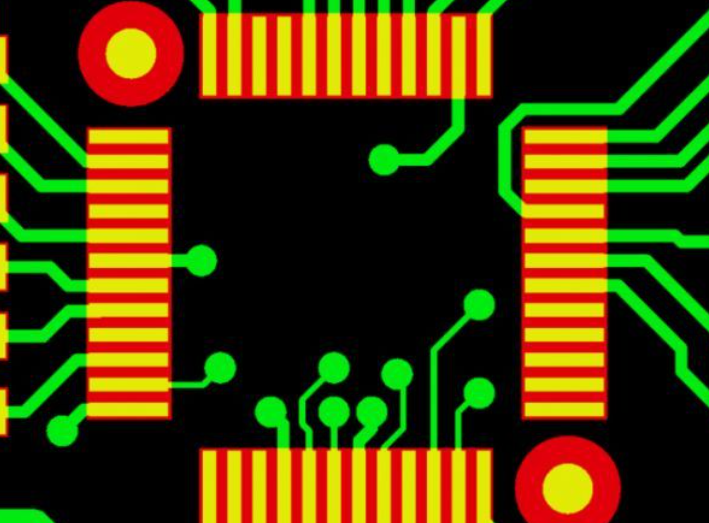

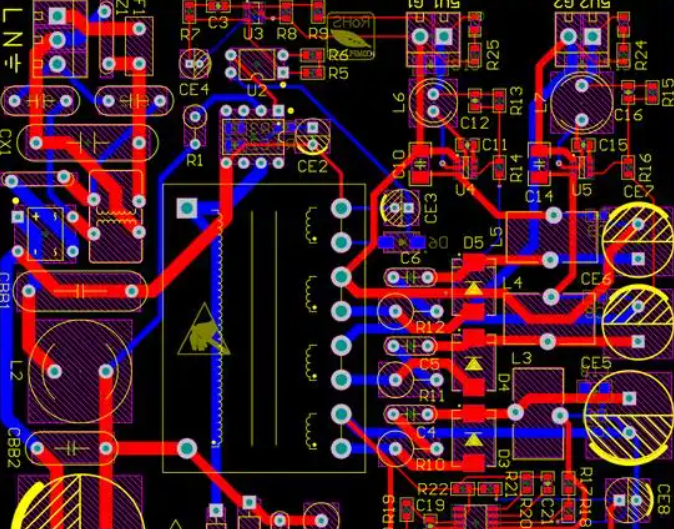

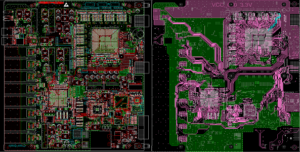

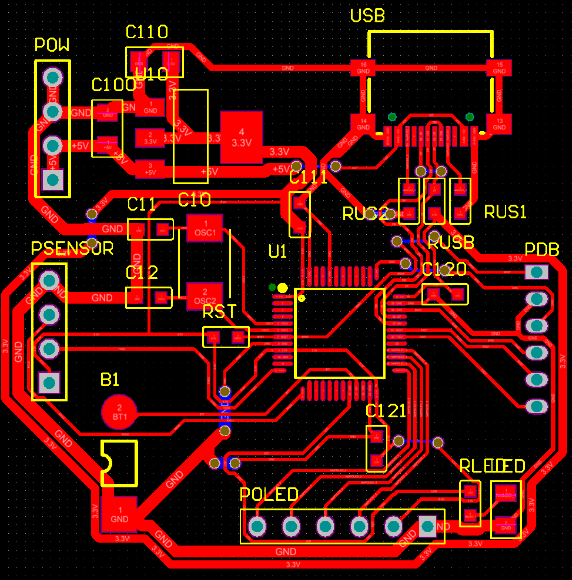

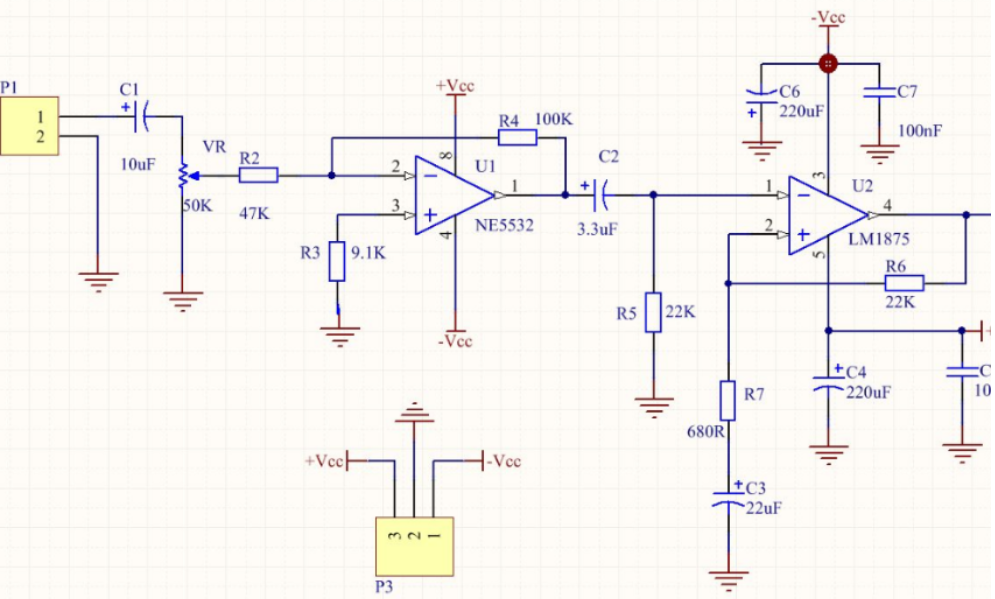

Design: First, the designer uses CAD software to design the circuit diagram and convert it into a PCB layout. This process includes determining the connection method of the circuit, the location of components, etc.

âFilm making: The designed circuit diagram is made into a transparent film sheet through a photoplotter for exposure.

âCoating: A layer of photosensitive material, usually photoresist, is coated on the substrate. This layer of material changes when exposed, and the unexposed part will be removed in the subsequent development process.

âExposure: The film is covered on the substrate coated with the photosensitive material, and the photosensitive material is cured by ultraviolet exposure.

âDevelopment: Remove the unexposed photosensitive material and leave the circuit pattern.

âEtching: Use chemical etchants to remove the copper foil that is not protected by the photosensitive material to form conductive lines and pads.

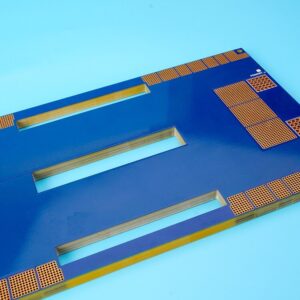

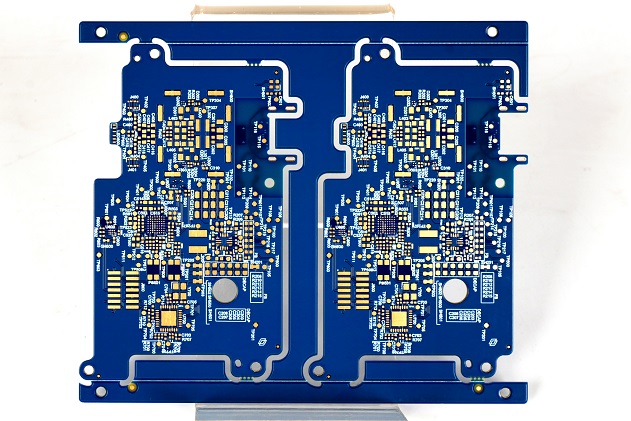

âLamination: Laminate multiple layers of circuit boards together to form a multi-layer PCB.

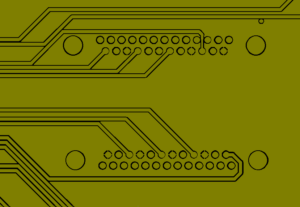

âDrilling: Drill corresponding holes on the board according to the design requirements for connecting different circuit layers.

âPlating: Electroplating metal in the hole to form a conductive path.

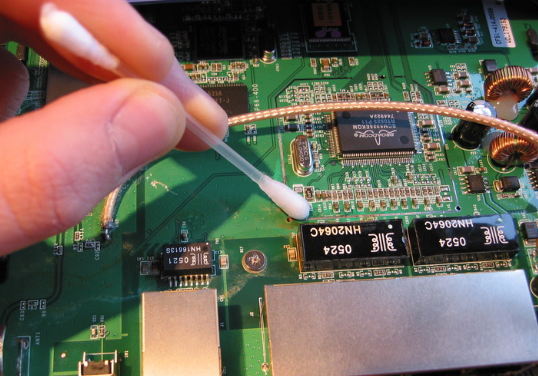

Surface treatment: PCB surface is treated, such as tin plating, gold plating, etc., to protect the copper foil and improve welding performance.

Kow long it takes to get pcb board from manufacturing

how long it takes to get pcb board from manufacturing?The time to manufacture a PCB depends mainly on the number of layers and complexity of the PCB.

âDouble-sided boardâ: Prototyping usually takes 1-3 days, and mass production takes about 5 daysâ.

â4-6 layer boardâ: Prototyping takes 2-4 days, and mass production takes 5-10 days.

â8-layer boardâ: Prototyping takes about 3-5 days, and mass production takes 7-15 days

How much does it cost to manufacture a pcb board

how much does it cost to manufacture a pcb board?The price of PCB boards varies depending on many factors, including the number of layers on the board, special requirements, quantity, etc.

Main factors affecting the price

â Number of layers of the boardâ: The more layers, the higher the price. For example, the price difference between a double-sided board and a four-layer board is largeâ.

â Special requirementsâ: Special materials, processes, or designs will increase the costâ.

â Quantityâ: When the order quantity is large enough, the unit price may be reduced or even exempted from additional feesâ.

â Proofing quantityâ: The more proofing quantity, the lower the unit priceâ.

What is a bom in pcb manufacturing and design

what is a bom in pcb manufacturing and design?BOM (Bill of Materials) is a technical document that describes the composition of a company’s products. It lists in detail the raw materials, parts, components, etc. required for the product, and indicates their quantity, specifications, etc. BOM plays a vital role in the manufacturing and design process.

What is design for manufacturability dfm for pcb’s

what is design for manufacturability dfm for pcb’s?DFM inspection refers to a comprehensive inspection of the design files after the PCB design is completed to ensure that the design meets the manufacturing process and requirements. The main purpose of DFM inspection is to find and solve problems in the design to ensure the manufacturability and reliability of the product.

Component layout: Check whether the layout of components is reasonable.

âLine width and line spacing: Ensure that the line width and line spacing meet the manufacturing requirements.

âImpedance control: Check whether the impedance control is accurate.

Through reasonable DFM design and DFM inspection, the manufacturing performance of the product can be improved, the production cost can be reduced, the product quality and reliability can be improved, and the product development cycle can be shortened. Therefore, in PCB design, the role of DFM should be fully valued and incorporated into the design process to achieve better product design and manufacturing effects.

DFM has the following important significance in PCB design:

âReducing costs: Through reasonable DFM design, the scrap rate in the production process can be reduced, the production efficiency can be improved, and the production cost can be reduced.

âImproving quality and reliability: By optimizing the layout and design, reducing electromagnetic interference, signal crosstalk and other problems, and improving the performance and reliability of the product.

âShortening the development cycle: Taking into account the manufacturing process and requirements in the design stage can avoid later modifications and adjustments and increase the speed of product launch.

FAQ About PCB

Do you have the ability to place bare dies on FR2?

Itâs no problem for us to place bard dies on FR2, wire bonding and seal with glob top. Please send us details such as: IC type (CMOS, TTL, etc), Wire type & diameter, glue type (conductive or non-conductive), products on high or low cost market. Etc. And our Metal dome is okay on FR2 as well.

What is the minimum copper thickness you can produce?

We can produce a minimum copper thickness of 1oz (18um).

How do you apply solder paste during production?

Solder paste is applied using stencil printing after silkscreening. The temperature for reflow soldering is set between 150-180°C.

Do you have your own factory? Are you an OEM?

Yes, we have our own SMT factory.

What material is smt stencil made of?

The edges of the SMT stencil are usually made of hollow aluminum frames (unless there are special customer requirements).

How much area can you produce daily?

Approximately 500 square meters per day.

What is the maximum board thickness you can produce?

The maximum thickness we can produce is 10mm.

What is the minimum stencil thickness you can make?

0.08mm, 0.10mm, 0.12mm

What is the minimum distance from the hole to the PCB?

0.25mm

What thermal conductive materials do you provide?

We use RS-2000 5GLM from Taiyo for thermal conductivity.