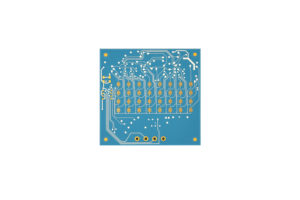

Designing and developing printed circuit boards (PCBs) may sound complex, but it’s an exciting process that is within reach, even for beginners. With the right approach, software tools, and an understanding of the basic principles, you can create functional and efficient PCBs.

Is PCB Design Difficult?

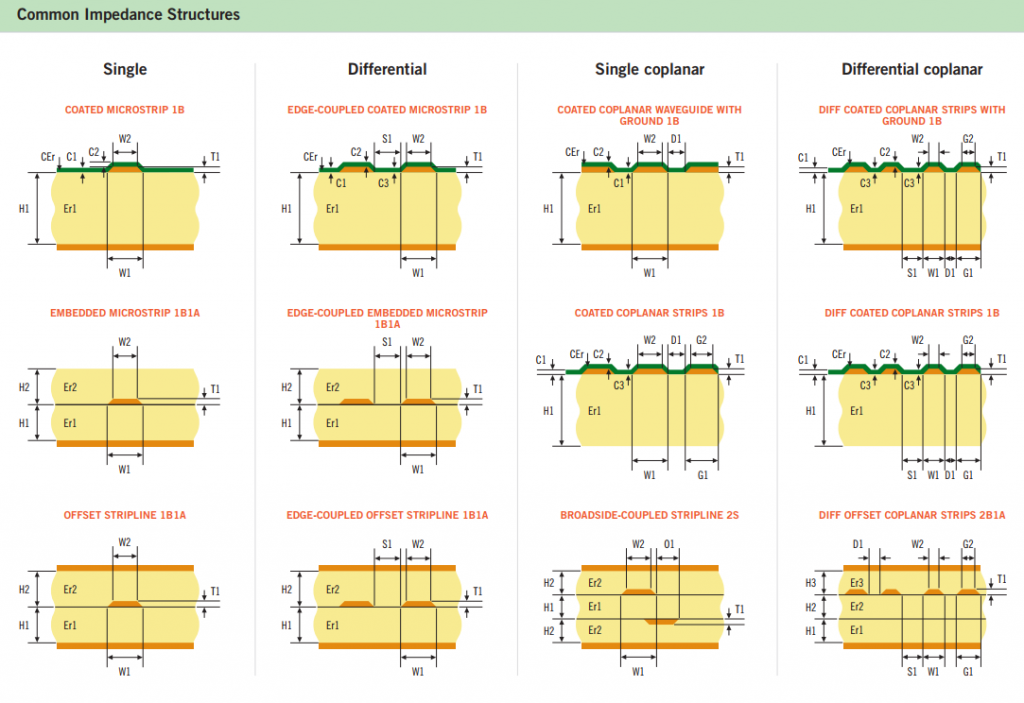

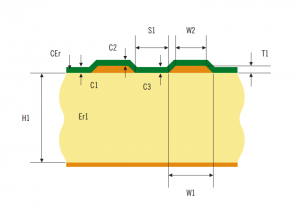

The difficulty of PCB design depends on the learning objectives and depth. If it is just the initial stage, do some simple circuit board design, then it is relatively easy. But if you want to go deep and get to expert level, in areas as diverse as pcb layout, signal integrity, electromagnetic compatibility, impedance design, and more, then you need to put in more work.

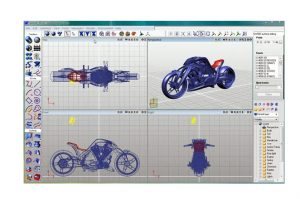

For beginners, choosing the right software and learning resources is very important. PADS from Protel, Altium Designer (AD) and Mentor Graphics are commonly used PCB design software. Protel software is simple and easy to learn, suitable for beginners to use; AD and PADS are powerful, but the operation is complex, suitable for the design of complex circuit boards.

What is the Basic Rule of PCB Design?

The key to good PCB design is layout organization. Keep the design simple, especially at the beginning. Here are a few basic rules to follow:

- Control Trace Length

Controlling the length of traces means adhering to the rule of keeping traces as short as possible in PCB design to avoid unnecessary interference caused by long traces. This is especially crucial for important signal lines, such as clock signal traces, which should be placed very close to the oscillator. When driving multiple devices, the network should be determined based on specific circumstances.

- Avoid Forming Self-Inductive Loops

In PCB design, it is important to pay attention to signal lines forming self-inductive loops between different layers, particularly in multilayer boards. The chances of forming self-inductive loops increase when routing signal lines between layers, and these loops can cause radiated interference.

- Minimize Ground Loop Principle

The principle of minimizing ground loops is to keep the signal lines and their loops as small as possible. The smaller the loop area, the less external radiation and interference it experiences. When defining ground planes, consider the distribution of the ground plane and important signal lines to prevent issues caused by ground plane cuts.

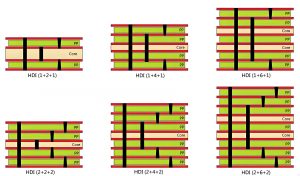

In double-layer board designs, while leaving sufficient space for the power supply, the remaining areas should be filled with reference ground and include some necessary vias to effectively connect signals on both sides. Ground isolation should be used for key signals. For designs with higher frequencies, special attention should be paid to the signal loop problems of the ground plane, and multilayer boards are recommended.

- High-Speed Signal Shielding Design

The relevant ground loop rules are also aimed at minimizing signal loop areas and are mainly used for important signals such as clock and synchronous signals. For particularly important and high-frequency signals, consider using a shielded structure design with copper coaxial cables. This means isolating the line from the ground on all sides while effectively grounding the shield layer and ensuring its connection with the ground plane.

- Avoid the “Antenna Effect”

Generally, routing with one end suspended is not allowed to avoid the “antenna effect,” which reduces unnecessary interference radiation and reception; otherwise, it may lead to unpredictable results.

- Chamfer Rule

PCB design should avoid sharp corners and right angles to prevent unnecessary radiation and poor manufacturing performance. The angle between all traces should be ≥135°.

- Avoid Overlapping Different Power Layers

Different power layers should be spatially separated to reduce interference between them, especially between power supplies with significant voltage differences. Issues arising from overlapping power planes must be avoided, and if unavoidable, consider using an isolated ground layer.

- Avoid Via Proximity to SMT Pads

If vias are not covered with a solder plug, they can easily be placed too close to SMT pads during layout. This can cause solder to flow through the via to the other side of the PCB during reflow, resulting in insufficient solder on the SMT pads and causing issues like cold solder joints. It is generally recommended to maintain a distance of more than 25 mils from the edge of the via to the SMT pad and to apply solder mask over the via.

- Do Not Route Traces Wider than SMT Pads Directly into the Pads

If traces are wider than the pads, the window area of the SMT pads generally expands beyond the pad size. This means that if the solder paste on the pad is slightly insufficient during reflow, there is a risk of cold solder joints. Using traces that are slightly larger or slightly smaller than the pads can also help avoid excessive heat dissipation during soldering.

- Do Not Place Components Too Close to the Board Edge

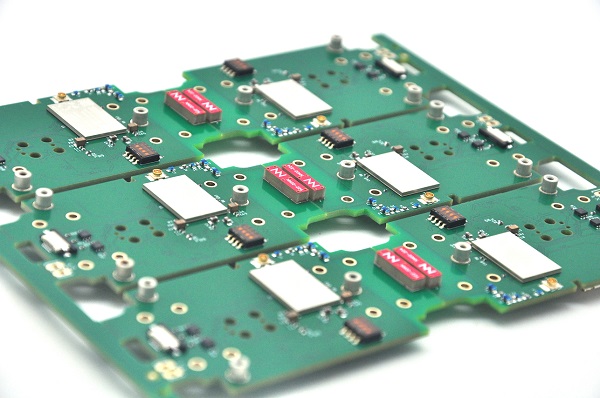

During the assembly and soldering stages of the PCB, the board will be transported through various processing areas, such as solder paste application and pick-and-place machines, followed by reflow soldering. Therefore, when designing the PCB, at least one side must leave enough space for a processing margin of at least 3 mm in width and 50 mm in length. There should be no interference between components and leads within the processing margin, as this could affect the normal transport of the PCB.

If the layout cannot accommodate this, consider adding an independent 3 mm processing margin or panel. (Note: SMT components cannot be placed within 5 mm of the edge on either side of the processing panel to facilitate reflow soldering.) If the components on your PCB are hand-soldered, you can disregard this requirement.

- Keep Solder Mask Window Sizes Consistent

The solder mask layer needs openings for the pads. These openings prevent the solder mask from covering the pad area, protecting the PCB circuit from oxidation and short circuits during soldering. Typically, a solder mask layer covers the outer layers of the PCB. Common solder masks are green (though black, red, yellow, and blue are also used).

Solder should not be applied to pads to avoid solder paste sticking. To avoid the solder mask layer interfering with pad solderability due to process tolerances, it is common to design a solder mask opening that is larger than the pad by approximately 0.1 mm (4 mil). However, it is also acceptable to keep the solder mask opening area the same size as the pad dimensions; the factory will process it uniformly for you.

- Reduce EMI Interference

Every PCB can be affected by EMI or become a source of interference. As part of the engineering design, special attention is required during PCB layout:

- Increase the spacing between high-frequency traces and low-frequency or analog traces.

- Minimize the return path for high-speed signals and ensure they do not cross split planes. Smaller current loops reduce EMI radiation intensity.

- High-speed differential signals should be routed in parallel and have equal lengths; otherwise, they will offset the noise suppression characteristics of the differential pair.

- Avoid using vias on high-speed traces, as they may lead to EMI emissions.

What Files Are Needed to Manufacture a PCB?

When you’re ready to manufacture your PCB, you will need to generate specific files for the fabrication process. The most common file format used by PCB manufacturers is the Gerber file. Here are some other important files that needed to submitted to manufacturer:

1. Gerber Files – your design files, include the design layout, detailing copper layers, solder masks, and silkscreen layers.

2. Drill Files – specify the locations and sizes of holes for vias and component leads.

3. Bill of Materials (BOM) – a list of all components required for the board, including part numbers and quantities.

4. Pick and Place File – guides the automated machines on where to place each component on the PCB.

What Software to Use for PCB Design?

Choosing the right software can make the design process much easier, especially for beginners. Here are a few commonly used PCB design tools:

- KiCad: This is a free, open-source software that’s great for both beginners and professionals. It has a user-friendly interface and includes a schematic editor, PCB layout, and 3D viewer.

- Eagle: Popular among hobbyists, Eagle offers a simple design process and an extensive component library. It’s free for small designs but has premium features for more advanced projects.

- Altium Designer: For more complex projects, Altium Designer is an industry-standard tool with advanced features. While it’s pricier, it offers professional-grade tools for high-level PCB design.

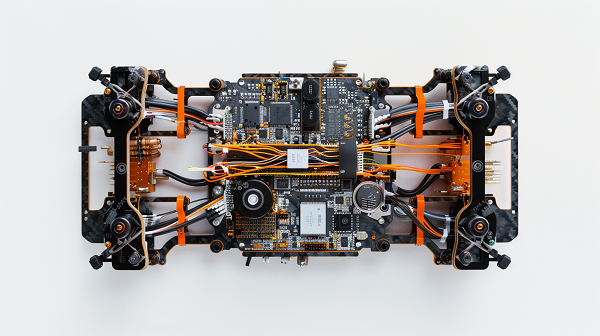

How Do You Manufacture a PCB Board?

Manufacturing a PCB involves several steps, and understanding the process helps ensure your design is ready for production. Here’s a simplified overview:

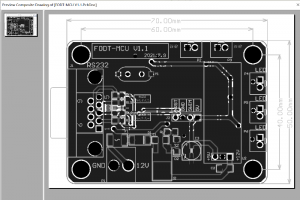

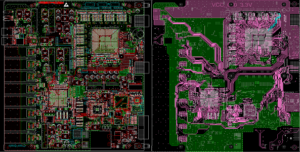

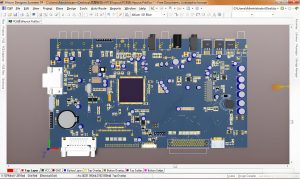

Step 1: Designing the PCB

Using PCB design software to create the PCB layout. The design process includes defining the schematic, component placement, and trace routing. Designers must consider factors such as signal integrity, power distribution, and thermal management.

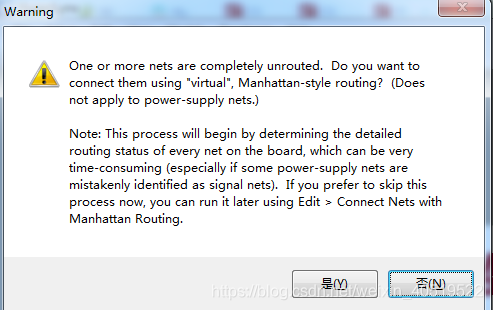

Step 2: Design Review and Engineering Questions

Once the initial design is complete, a thorough review is conducted. This includes checking for design rule violations, verifying component footprints, and ensuring all connections are correct. Engineers may raise questions about potential performance issues, manufacturability, and compliance with regulatory standards. Feedback from this review may lead to modifications to optimize the design.

Step 3: Printing the PCB Design

After finalizing the design, the PCB layout is printed onto a transparent film, which will be used as a photomask for the etching process. This film represents the layers of the PCB, including copper and solder mask layers.

Step 4: Printing the Copper for the Interior Layer

The copper layers are printed onto the laminate using a photoresist process. The photoresist is applied to the copper-clad laminate, and the printed film is exposed to UV light. The areas that are exposed to light will become soluble and can be washed away, leaving behind a copper pattern that matches the PCB design.

Step 5: Etch the Inner Layers or Core to Remove Copper

The exposed copper is etched away using a chemical process, leaving only the desired copper traces. This step must be carefully controlled to ensure the traces are of the correct width and spacing, as specified in the design. The etching process can be done using either chemical etching or laser etching.

Step 6: Layer Alignment

Once the inner layers are etched, they must be aligned correctly for lamination.

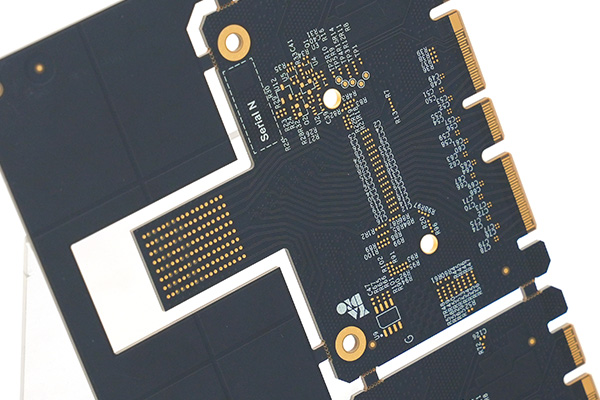

Step 7: Automated Optical Inspection (AOI)

Automated Optical Inspection is performed to check the accuracy of the printed copper layers. Any discrepancies, such as missing or misaligned traces, can be identified and corrected before proceeding to the next steps.

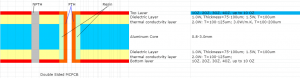

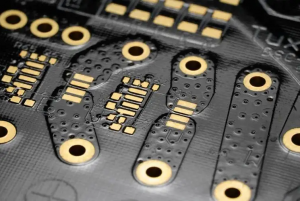

Step 8: Laminating the PCB Layers

The aligned layers are then laminated together using heat and pressure. It combines the different layers, including copper, dielectric, and solder mask layers, into a single, solid structure.

Step 9: Drilling

Once the layers are laminated, holes are drilled for vias and mounting holes. The drilling process requires precision, as these holes must align perfectly with the design specifications. Computer-controlled drilling machines are typically used to achieve the necessary accuracy.

Step 10: PCB Plating

After drilling, the PCB goes through an electroplating process where a conductive layer is added to the walls of the drilled holes.

Step 11: Outer Layer Imaging

Similar to the inner layers, the outer layers are prepared for imaging. A photoresist is applied, and the printed film of the outer layer design is aligned and exposed to UV light. The unwanted areas are washed away, leaving a pattern on the copper layer.

Step 12: Outer Layer Etching

The outer copper layers are then etched to remove the unprotected copper, leaving behind the desired copper traces.

Step 13: Outer Layer AOI

Another round of Automated Optical Inspection is conducted on the outer layers to ensure that the copper traces and pads are correctly formed.

Step 14: Solder Mask Application

A solder mask layer is applied to protect the PCB and prevent solder from bridging between components during assembly. The solder mask is typically a green epoxy coating, but it can also be available in other colors. The areas where solder is needed are left exposed.

Step 15: Silkscreen Application

Silkscreen printing is used to apply labels, component designators, logos, and other markings onto the PCB surface.

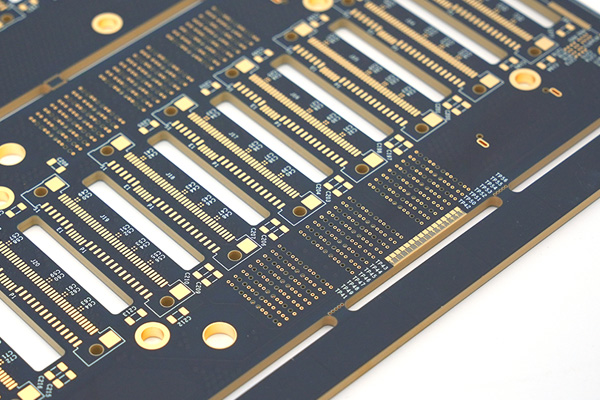

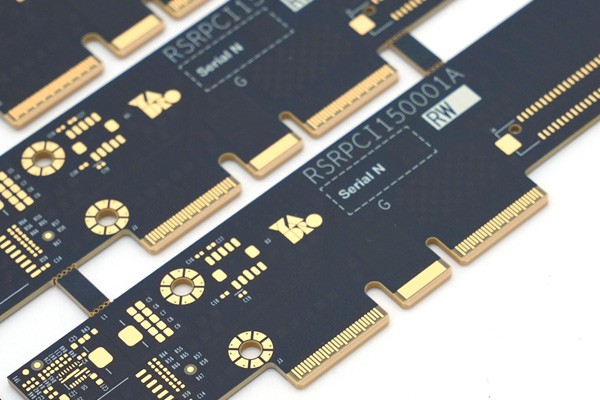

Step 16: Finishing the PCB

The finishing process includes applying surface finishes such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservative) and so many surface treatments.

Step 17: Electrical Reliability Test (E-test)

Before packaging, the PCBs undergo electrical testing to ensure that all circuits function correctly. This may include continuity testing, insulation resistance testing, and high-voltage testing.

Step 18: Profiling and Route Out

The final PCB is profiled and routed to its specific shape, including cutting out the edges and any slots or cutouts required.

Step 19: Quality Check and Visual Inspection

A final quality check and visual inspection are performed to ensure that all specifications have been met. Examining for any physical defects, such as scratches, solder mask misalignment, or improper solder application.

Step 20: Packaging and Delivery

Once all checks are complete, the PCBs are cleaned, packaged, and prepared for delivery. Proper packaging is essential to protect the PCBs during shipping.

What Is the Cheapest PCB Finish?

The cheapest finish is HASL, which is also widely used. HASL applies a thin layer of molten solder to the surface, providing good protection and easy solderability. However, it’s not always suitable for fine-pitch components or designs requiring a flat surface. Other options, such as ENIG (Electroless Nickel Immersion Gold), are more expensive but provide a smoother, more durable finish for advanced designs.

Developing a PCB for the first time can feel like a daunting task, but by understanding the basics and using the right tools, it’s a process that anyone can learn. From following simple design rules to choosing affordable software and finishes, creating a PCB can be a good experience. Working closely with manufacturers and learning through trial and error will sharpen your skills over time.

How Much Does It Cost to Get a PCB Board Made?

The cost of producing a PCB depends on several factors, such as the size, number of layers, material used, and whether you’re doing a prototype run or full production. For a simple, single-sided board, costs can start as low as $10 to $20 per board, but more complex, multi-layer designs can cost upwards of $100 or more per board.

Additional costs may include shipping, testing, and assembly if you are having components mounted by the manufacturer. It’s always a good idea to get quotes from multiple manufacturers and consider both cost and quality.

If you don’t want to develop a PCB board by yourself, choosing a reliable EMS PCB manufacturer like Best Technology. We are engaging in PCB manufacturing over 18 years, we deeply understand every design rules and know which one is best for manufacturing. Best Team offer full turnkey PCB & PCBA service for over the world. We can help to PCB design, PCB layout, PCB manufacturing, components sourcing, PCB assembly, box building, and function testing. Give us your ideal, we can make it come true!