4 layer PCB manufacturer is a phrase you’ll come across often when dealing with multilayer circuit board designs. These boards support more complex electronics, offering better performance in smaller spaces. Whether you’re building industrial devices or consumer electronics, a reliable 4 layer PCB partner can simplify your production process. This blog explores key factors you should consider and why choosing the right manufacturer is so important.

Established in 2006, Best Technology offers comprehensive engineering consulting services, including 4 layer PCB assembly with capabilities in FR4, HDI, rigid, rigid-flex boards, and MCPCB. Best Technology delivers 4 layer PCB manufacturing services with a focus on quality and customer satisfaction to 1700 customers across 40 countries. If you have any questions about 4 layer PCB manufacturing process or 4 layer PCB cost, welcome to contact us via sales@bestpcbs.com.

What is a 4 Layer PCB?

A 4 layer PCB is a printed circuit board with four layers of copper traces stacked together. It includes two outer layers and two internal layers. These internal layers are used for power and ground planes or routing signals.

Compared to a 2-layer board, this type allows for more routing space and better EMI control. That’s why it’s preferred in applications like embedded systems, communication devices, and consumer electronics.

Thanks to the additional layers, engineers get more room for complex circuits without increasing the board size. This makes it an excellent choice for compact and high-performance designs.

What is the Best Stackup for 4-Layer PCB?

Stackup matters a lot in any multilayer PCB. For 4 layer boards, the best stackup usually balances signal integrity, EMI control, and manufacturability.

The standard 4-layer PCB stackup looks like this: Top Layer – Inner Layer 1 – Inner Layer 2 – Bottom Layer. Here’s a common configuration:

- Top Layer (Signal)

- Inner Layer 1 (Ground)

- Inner Layer 2 (Power)

- Bottom Layer (Signal)

This arrangement keeps the signal layers next to the planes, which helps reduce noise and crosstalk. In some cases, designers may opt for different configurations based on signal speed or isolation needs. However, grounding between signal layers is one of the most effective ways to ensure signal stability.

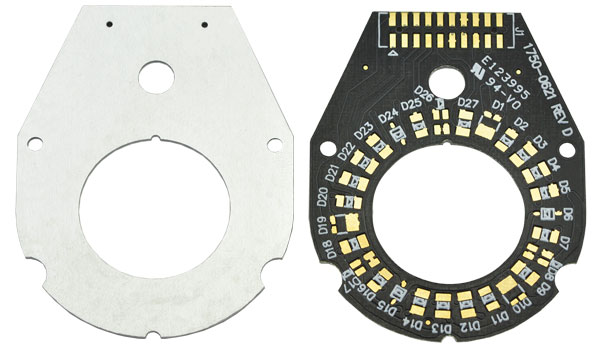

How Thick is a 4-Layer PCB Core?

PCB thickness is an essential spec. In a 4-layer board, the thickness can vary depending on the prepreg and core materials used.

A typical 4-layer PCB has a thickness of 1.6mm. This includes the core and prepreg materials between layers. For instance:

- Core thickness: around 0.8mm

- Prepreg layers: 0.2mm each

- Copper foil: 35µm or thicker depending on current requirements

If your design needs specific mechanical properties, you can go thicker or thinner. Many 4 layer PCB manufacturers offer customization for thickness. So, whether you’re working with handheld devices or industrial-grade equipment, there’s a solution that fits.

4 Layer PCB Manufacturing Process

The process of making a 4-layer board is more complex than single or double-layer boards. But it allows for higher performance. Here’s a quick walk-through:

Step-by-Step Overview:

Inner Layer Imaging and Etching

- The manufacturer starts with laminates. Patterns are transferred to the inner layers using a photoresist. Then, copper is etched away to form the desired traces.

Layer Lamination

- The etched inner layers are stacked with prepreg material and outer copper foils. This sandwich is then laminated under high heat and pressure.

Drilling

- Holes are drilled to connect the layers, including vias that link top to bottom.

Plating

- The drilled holes are electroplated with copper to ensure conductivity across layers.

Outer Layer Imaging and Etching

- Similar to the inner layer, patterns are added to the outer surfaces and etched.

Solder Mask and Surface Finish

- A protective solder mask is applied. Then, finishes like HASL, ENIG, or OSP are added to the pads for better solderability.

Silkscreen Printing and Testing

- Component labels are printed. Finally, every board goes through electrical testing to ensure performance.

This process ensures the board meets all functional and quality standards. A professional 4 layer PCB manufacturer maintains tight control during each step to avoid issues later.

How Much Does a 4 Layer PCB Manufacturer Charge vs 6 Layer?

Pricing always plays a major role. The cost of a 4-layer board depends on materials, size, and volume. On average, a 4-layer PCB may cost 25%–50% less than a 6-layer PCB of the same dimensions. Here’s why:

- Material use: Fewer layers mean less copper and prepreg.

- Processing time: Less time required for pressing and drilling.

- Testing cost: 6-layer boards need more in-depth electrical testing.

For basic 4-layer boards, pricing can start at $50–$100 per square meter for large batches. Complex designs or special materials may push it higher. That said, when you’re scaling production, the per-unit cost drops quickly.

4 Layer PCB Manufacturer India

Who is 4 Layer PCB Manufacturer India? India’s electronics manufacturing landscape is growing fast, and finding a reliable 4 layer PCB manufacturer is now easier than ever. With rising local demand and a push for domestic production, several Indian companies are offering world-class multilayer PCB solutions, including 4 layer PCB fabrication. Below manufacturers focus on quality, quick delivery, and affordable pricing, making them suitable for global and local clients.

1. Circuit Systems India Ltd. (CSIL)

- Based in Gujarat, CSIL is one of India’s well-known names in multilayer PCB manufacturing. With modern facilities and a global customer base, CSIL offers 4 layer PCBs with high reliability and quick prototyping. They serve industries such as telecom, automotive, and consumer electronics, ensuring strict process controls and RoHS compliance.

2. Shogini Technoarts Pvt. Ltd.

- Located in Pune, Shogini is a seasoned PCB manufacturer with more than 40 years of experience. They provide single to 8-layer boards and specialize in prototype and medium-volume production. Their 4 layer PCBs are used in power electronics, automotive, and industrial control sectors. Their in-house testing and customization capabilities help them deliver consistent results.

3. Genus Electrotech Ltd.

- Operating from Gandhinagar, Genus Electrotech is a leading end-to-end electronics manufacturer in India. Along with PCBA, they produce high-quality 4 layer PCBs for lighting, energy, and automation applications. Their fully automated facility supports high-volume runs and strict quality standards, making them a trusted choice for OEMs in India and abroad.

Choosing the right 4 layer PCB manufacturer in India can bring many benefits from cost savings to faster delivery and smoother communication. The companies listed above have strong reputations for quality, technical support, and scalability. Whether you need small batches or large-volume orders, working with Indian PCB manufacturers can offer great value while supporting your project timeline and performance needs.

How to Choose a 4 Layer PCB Manufacturer?

Choosing the right partner can save time, reduce costs, and improve final product quality. Here are a few things to look for:

Experience in multilayer PCBs

- Not every PCB manufacturer specializes in 4-layer boards. Make sure they’ve handled complex layouts and can offer design support.

Material flexibility

- Check if they work with your preferred substrates (FR4, High Tg, Rogers, etc.).

Certifications and quality control

- Look for ISO9001, UL, and IPC compliance. Also ask about in-house testing capabilities.

Customization and technical support

- Good communication and support for stackup optimization or impedance control are big pluses.

Turnaround time

- Fast delivery helps you stick to your project timelines. But don’t sacrifice quality for speed.

Scalability

- Choose a supplier who can handle low-volume prototyping and high-volume runs.

A reliable 4 layer PCB manufacturer won’t just deliver boards. They’ll act as a partner in your development journey.

Why Should You Choose Best Technology as Your 4 Layer PCB Manufacturer?

At Best Technology, we’re proud to be a trusted 4 layer PCB manufacturer serving clients worldwide. We’ve spent over 18 years fine-tuning our process to ensure consistent quality, fast delivery, and technical excellence.

Here’s what sets us apart:

Advanced manufacturing capability

- We handle complex stackups, blind and buried vias, controlled impedance, and more.

Strict quality control

- From AOI to flying probe and final inspection, we don’t miss a detail.

Global support team

- We work with clients across Asia, Europe, and the Americas. No matter where you’re located, our team responds fast and clearly.

Custom solutions

- Whether you need high-frequency 4-layer boards or standard FR4 designs, we can tailor the solution.

Sustainability

- Best Technology is capable of delivering high-quality multilayer boards with fast turnaround. Our factory is certified for international standards like ISO9001, ISO13485, IATF16949, AS9100D. We follow RoHS and REACH regulations and actively reduce waste in our process.

If you’re looking for a 4 layer PCB manufacturer that values reliability, communication, and results, Best Technology is here for you.

In conclusion, finding the right 4 layer PCB manufacturer can make a big difference in your electronics project. From understanding the stack up to managing cost and choosing a trustworthy partner, every step matters. India is growing fast in this space, offering excellent value. And when you need a partner with deep experience and full-service capability, Best Technology stands out with our quality and commitment. Reach out to us at sales@bestpcbs.com for a quick quote and expert support in your 4-layer PCB project.