The 380V AC board is a crucial component in industrial and commercial electrical systems, providing efficient power distribution to high-demand equipment. Whether you’re managing a manufacturing plant, operating large machinery, or overseeing complex HVAC systems, understanding how a 380V AC board works is essential for ensuring smooth operations and avoiding electrical issues. In this blog, we will explore the key features, benefits, and applications of 380V AC boards, as well as offer insights on how to choose the right one for your system.

At Best Technology, we specialize in high-quality PCBs, MCPCBs, FPCs, and ceramic PCBs that power a wide range of electrical and industrial systems. Our products are designed with precision and reliability to meet the demands of advanced applications, including those involving 380V AC boards for power distribution.

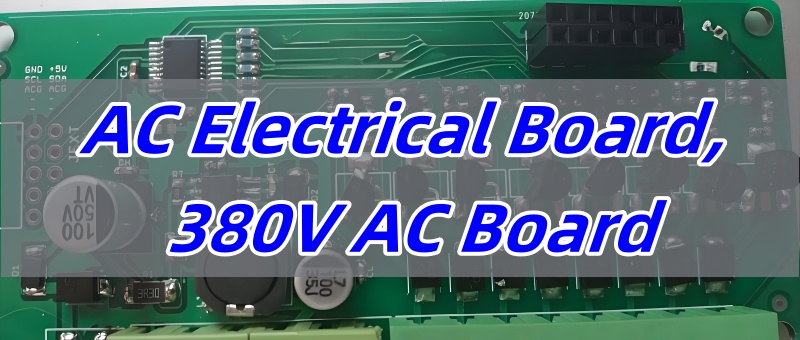

What is a 380V AC Board?

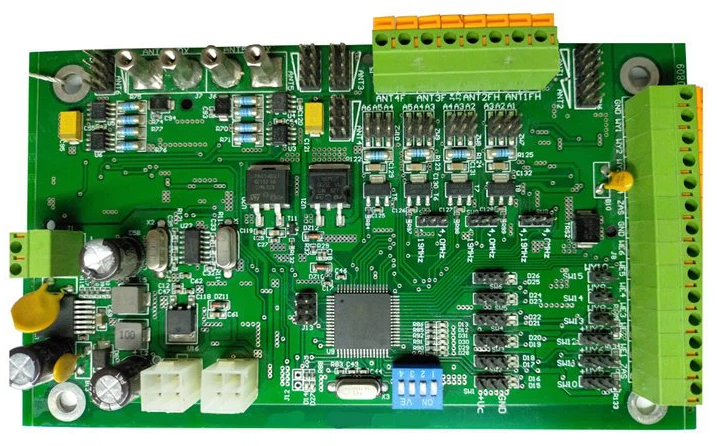

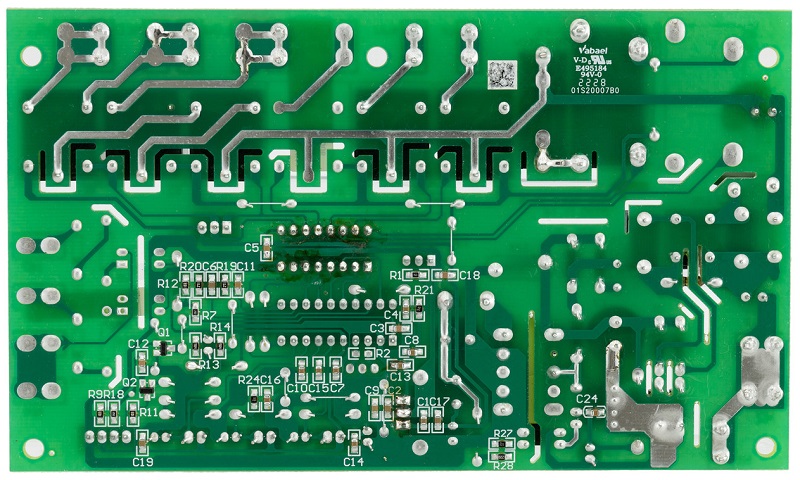

A 380V AC Board is an electrical control or distribution panel designed to safely manage and distribute 380-volt alternating current (AC) power in industrial or high-voltage systems. A 380V AC board is a critical component in electrical systems, particularly in industrial and commercial applications. This board helps distribute electrical power efficiently across various devices and machinery. Unlike standard voltage boards, the 380V AC board is designed to handle higher voltage levels, making it suitable for heavy-duty systems that require a stable and powerful energy supply.

Typically used in industrial environments, 380V AC boards are equipped with safety features to ensure smooth operation while preventing any electrical hazards. These boards play a key role in managing power distribution in large-scale operations, ensuring consistent performance for everything from production lines to high-powered machinery.

How Does a 380V AC Board Work?

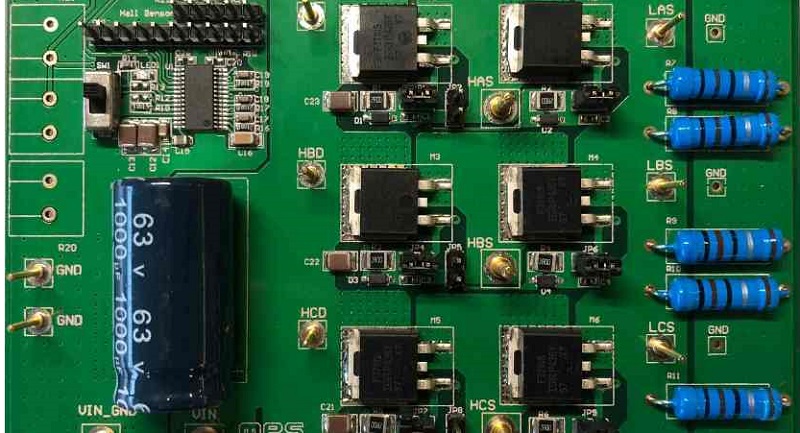

The 380V AC board works by controlling and directing electrical power from the source to various parts of the electrical system. It acts as the main hub in power distribution, ensuring that each device receives the correct voltage to operate efficiently. The board can also be designed with circuit breakers, fuses, and relays to provide protection and control over the electrical flow.

In simple terms, it takes high-voltage AC (Alternating Current) and distributes it across systems to maintain functionality. The power is converted and routed to different parts of a circuit as needed, ensuring that everything from lights to heavy machinery gets the energy it needs without overloading the system.

What’s the Role of AC Electrical Board in Power Distribution?

AC electrical board, including the 380V AC board, plays a central role in power distribution. They ensure that electrical power is delivered safely and efficiently from the main power supply to various circuits. Without these boards, it would be challenging to manage high-power requirements, particularly in industrial sectors where large machines and systems need consistent energy.

These boards help organize circuits, prevent overloads, and ensure that the right voltage reaches the correct equipment. For example, in factories, they allow for the seamless operation of production lines by ensuring that all machinery receives the right voltage for operation, minimizing the risk of faults and downtime.

What’s the Key Difference Between 380V AC Boards and Standard Voltage Boards?

The primary difference between a 380V AC board and a standard voltage board lies in the voltage levels they handle. A standard voltage board typically operates at lower voltages, such as 120V or 240V, while a 380V AC board is designed to handle higher voltage levels, often required for industrial or commercial applications.

This higher voltage capability of the 380V AC board allows it to power more energy-intensive systems, such as large machinery or high-performance HVAC systems. Furthermore, 380V AC boards are built to be more robust and equipped with additional safety features to handle these higher loads without compromising system integrity.

What Are the Benefits of Using 380V AC Boards in Electrical Systems?

Using a 380V AC board in electrical systems offers several benefits. First, it supports the distribution of power across larger, more complex setups, which is essential in industrial settings. With a 380V AC board, businesses can manage their energy needs more efficiently, avoiding the need for separate power sources or additional transformers.

Moreover, these boards help increase the reliability of electrical systems. They are built to handle higher loads and ensure that everything, from lighting to heavy machinery, operates seamlessly. The 380V AC board also ensures energy efficiency, as it minimizes energy loss during transmission.

Another significant advantage is safety. These boards are equipped with built-in protection features, such as overload protection and short-circuit prevention, ensuring that electrical faults do not damage expensive equipment or cause potential hazards.

What Are the Common Applications of 380V AC Boards in Industrial Equipment?

380V AC boards are widely used in industries that require stable and reliable electrical power. Common applications include:

Manufacturing Plants: 380V AC boards power heavy machinery, assembly lines, and other equipment that demands high-voltage electricity.

HVAC Systems: Many commercial and industrial HVAC systems operate on 380V power, and the boards help regulate and distribute the required energy efficiently.

Pumps and Motors: Large pumps and motors used in water treatment plants, chemical processing, and mining often rely on 380V AC boards for consistent energy supply.

In fact, anywhere large, energy-intensive equipment is used, you’ll likely find a 380V AC board ensuring that everything runs smoothly and efficiently.

How to Safely Install and Maintain a 380V AC Board?

Safety is crucial when dealing with 380V AC boards, and proper installation and maintenance are key to preventing electrical hazards. Here are some tips:

Professional Installation: Always hire a licensed electrician with experience working with high-voltage systems to install your 380V AC board. Proper installation ensures safe wiring and minimizes the risk of faults.

Regular Inspections: Periodically check the board for signs of wear or damage. Pay attention to circuit breakers, fuses, and wiring to ensure they’re in good working order.

Clearances and Ventilation: Ensure that the board is installed in a well-ventilated area with adequate clearance for heat dissipation. Overheating can lead to system failure.

Use Proper Safety Gear: When maintaining or inspecting your board, always wear the necessary protective equipment, such as rubber gloves and safety goggles.

By following these steps, you can ensure the safe operation of your 380V AC board while preventing common electrical hazards.

How to Choose a 380V AC Board for Your System?

Choosing the right 380V AC board for your system requires considering several key factors:

Power Requirements: Ensure the board can handle the power demand of your system. You’ll need a board that can provide the necessary current without risk of overload.

Safety Features: Look for boards with built-in protection features such as overload protection, short-circuit protection, and thermal monitoring.

Size and Compatibility: Consider the size of the board and ensure it fits within your existing system’s layout. It’s also essential that it is compatible with the other electrical components in your system.

Manufacturer Reputation: Select a board from a trusted manufacturer that offers quality and durability. Ultimately, selecting the right 380V AC board ensures that your electrical system remains efficient, reliable, and safe.

In conclusion, understanding the role and benefits of 380V AC boards is crucial for anyone involved in industrial or commercial electrical systems. From their ability to power high-demand equipment to ensuring safe power distribution, these boards play an integral part in maintaining the efficiency and reliability of operations. Whether you’re installing a new system or upgrading an existing one, make sure to choose the right board based on your power needs, safety requirements, and system compatibility.

As a trusted leader in the PCB manufacturing industry, Best Technology provides cutting-edge solutions that support the efficient operation of complex systems in sectors like automation, manufacturing, and energy. Whether you’re looking to enhance the performance of your electrical systems or integrate custom solutions, Best Technology is your partner for innovation and quality in PCB design and production. If you need seamless, high-performance solutions for your industrial and electrical needs, reach out to us at sales@bestpcbs.com for more information.