AlN PCB stands out as a top choice when companies need strong heat management and reliable performance in advanced electronics. This ceramic PCB substrate uses aluminum nitride, known for its high thermal conductivity and excellent electrical insulation. With electronics getting smaller and more powerful, keeping heat under control is more important than ever. That’s why many industries rely on AlN ceramic PCB to improve both performance and reliability.

At the same time, customers often want to know how AlN PCB fabrication works, how it compares to other options, and what affects its final price. Understanding these details helps engineers and buyers make smarter choices for their projects. In this blog, we’ll explore everything from the properties of aluminum nitride to the benefits, pricing factors, and even common assembly challenges.

If you’re searching for a reliable ceramic PCB substrate or want to understand how AlN PCB fits into your next design, this guide will help. Whether you’re working on high-frequency devices, power modules, or advanced communication systems, knowing the strengths of AlN PCB can make a big difference.

What is aluminum nitride PCB material?

AlN PCB stands for aluminum nitride PCB, which uses aluminum nitride ceramic as the base material. It is known for excellent thermal conductivity, strong electrical insulation, and reliability in harsh environments. Compared to standard FR4 boards, AlN PCB supports much better heat dissipation. That’s why engineers choose this material for high-power circuits, laser systems, and advanced communication devices.

Aluminum nitride acts as both the base and heat spreader. This unique structure reduces thermal stress, helping sensitive components stay cooler. As technology grows, more industries lean toward AlN PCB to handle performance needs.

Is aluminum nitride a ceramic?

Yes, aluminum nitride is a ceramic. It belongs to the advanced ceramic family, valued for its high strength, electrical insulation, and outstanding heat transfer abilities. Unlike traditional ceramic materials, aluminum nitride supports fast heat removal, which helps extend component life.

Since AlN is ceramic, it also resists chemicals, high temperatures, and mechanical wear. These benefits make it suitable for AlN ceramic PCB manufacturing. Today, designers rely on it for high-frequency devices, power electronics, and communication modules.

Is Aluminium nitride brittle?

Like other ceramics, aluminum nitride is somewhat brittle, especially under sudden mechanical shock. However, it still performs better than some other ceramics used in electronics. Proper design, combined with experienced fabrication techniques, helps reduce risks related to brittleness.

The good news is that once AlN PCB fabrication completes and the board is installed correctly, its durability is impressive. This balance of strength, heat management, and electrical insulation keeps AlN ceramic PCBs in high demand across industries like automotive, aerospace, and telecom.

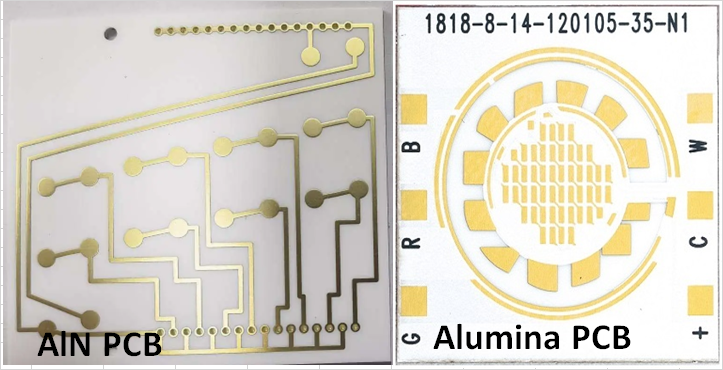

How does AlN PCB compare to alumina PCB in thermal performance?

Thermal performance directly affects the reliability of modern electronics. When comparing AlN PCB to alumina PCB, aluminum nitride performs much better in heat transfer. Its thermal conductivity reaches around 170-200 W/mK, which is far higher than alumina’s 20-30 W/mK.

This major difference matters when components generate heat in compact spaces. Devices that push high power levels or require stable performance over time benefit from this advantage. While alumina PCB offers good insulation and is more affordable, AlN remains the first choice for heat-sensitive applications.

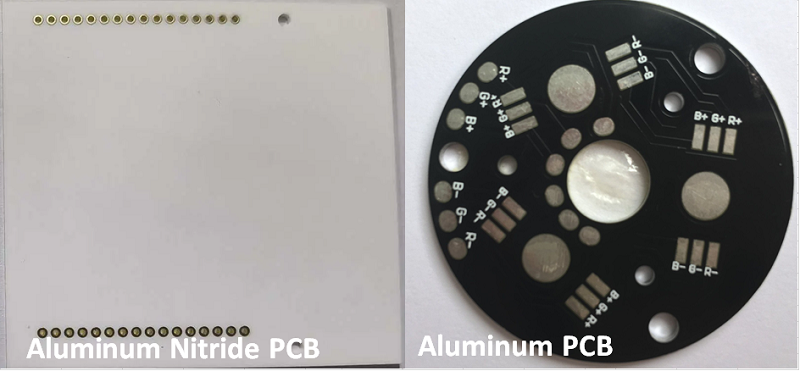

What is the difference between aluminum nitride PCB and aluminum PCB?

This is a common question from customers comparing materials. AlN PCB uses a ceramic core made from aluminum nitride, while aluminum PCB uses a metal aluminum base with a dielectric layer on top. Both manage heat, but they work in different ways.

AlN ceramic PCB offers excellent electrical insulation, which allows designers to place components closer together. It also handles extreme heat better without expanding too much. On the other hand, aluminum PCB, though cheaper, has limited electrical insulation, making it less suitable for high-frequency and precision circuits.

In short, AlN PCB fits better where thermal management and signal performance both matter. Aluminum PCB works well in simpler applications where cost matters more than advanced performance.

What factors affect AlN PCB price?

Several factors affect AlN PCB price, and understanding them helps customers plan projects better. First, the raw material cost plays a key role. Aluminum nitride is more expensive than standard PCB materials, but the benefits often outweigh the cost.

Next, fabrication complexity impacts price. Multilayer designs, micro vias, and precision routing need advanced technology, adding to the total. Batch size also matters. Larger runs usually lower the cost per piece, while small or custom orders cost more.

Lastly, surface treatment choices, tolerances, and assembly needs contribute to the final cost. That’s why working with an experienced AlN PCB fabrication supplier helps balance price and performance.

What are common PCB assembly issues with AlN ceramic PCBs?

Even with advanced materials like AlN ceramic PCB, assembly issues can happen without careful handling. One common challenge is matching the thermal expansion of components with the ceramic base. Sudden thermal changes can stress solder joints if not managed well.

Another potential issue comes from the surface finish. Choosing the wrong finish for high-frequency circuits or high-temperature processes can lead to signal loss or poor solderability.

Lastly, poor handling during assembly can crack the ceramic substrate. This highlights the importance of choosing experienced assembly partners with expertise in AlN PCB fabrication and assembly. By working with a trusted supplier, these risks can be minimized, improving reliability and performance.

What is the use of Aluminium nitride?

Aluminium nitride offers broad uses across multiple industries. Its high thermal conductivity makes it perfect for high-power electronics, such as laser drivers, RF amplifiers, and power modules. These systems generate heat that needs to move away quickly to protect components.

Besides electronics, AlN ceramic plays a role in NFC communication systems, where thermal stability and electrical insulation enhance performance. Medical devices also benefit from aluminum nitride’s biocompatibility and thermal management properties.

In short, AlN PCB supports applications that demand precise performance, stability, and long-term reliability, especially under demanding conditions.

How to select the right manufacturer for AlN PCB fabrication?

Selecting the right AlN PCB fabrication partner directly affects project success. Start by checking the manufacturer’s experience with ceramic PCB substrates. Not all PCB companies have the technology or skills to handle aluminum nitride.

Next, ask about in-house capabilities for drilling, plating, and precision routing. AlN requires specialized equipment and processes, so a capable supplier handles every step under one roof. This ensures quality control and reduces lead times.

Also, consider the manufacturer’s knowledge in PCB assembly issues, especially for ceramics. Experienced suppliers know how to manage thermal stress, select the right surface treatments, and optimize designs for both performance and manufacturability.

Finally, check for customer support and willingness to provide design advice. A good partner not only builds your boards but also helps improve designs to balance performance, cost, and reliability.

In a nutshell, choosing AlN PCB means investing in better thermal performance, electrical insulation, and reliability. With growing demand for aln ceramic pcb in high-power and high-frequency applications, more engineers turn to this advanced material.

Working with a professional AlN PCB fabrication partner ensures your boards meet both performance and cost goals. If you’re looking for a ceramic PCB substrate that can handle the heat, aluminum nitride offers one of the best options available.

At Best Technology, we specialize in advanced ceramic PCBs, including AlN inlay PCB, alumina PCB, and more. Our experts understand the challenges of aln pcb fabrication and assembly issues, delivering high-quality boards for demanding projects. For more information or inquiries, feel free to contact us at sales@bestpcbs.com.