Laser direct imaging (LDI) is an advanced PCB manufacturing technology that uses a computer-controlled laser beam to directly expose circuit patterns on a PCB substrate coated with photosensitive material. This technology can achieve high-precision imaging effects and significantly improve production efficiency and imaging quality.

What is laser direct imaging?

Laser Direct Imaging (LDI) is an advanced PCB manufacturing technique that directly transfers circuit patterns onto a photoresist-coated board using laser technology.

Unlike traditional photolithography, which relies on photomasks, LDI uses computer-controlled lasers to etch intricate designs with extreme precision.

This method significantly enhances accuracy, speed, and flexibility, making it a preferred choice for modern PCB production, especially for high-density interconnect (HDI) boards.

How does LDI differ from traditional imaging?

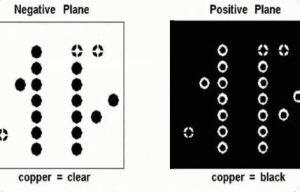

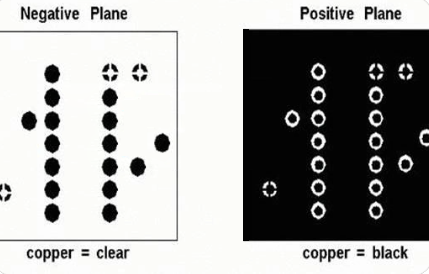

Traditional PCB imaging depends on photomasks to transfer circuit designs onto the PCB. This process involves multiple steps, including photomask fabrication, manual alignment, and exposure to UV light.

Since photomasks are physical templates, they can degrade over time, leading to inconsistencies in production.

LDI eliminates these challenges by using digital laser beams to expose the photoresist layer directly, ensuring greater precision and efficiency. Here’s how LDI stands out:

- No photomasks required ‚Äď Eliminates costs and maintenance associated with masks.

- Higher precision ‚Äď Laser beams can achieve much finer line widths than traditional methods.

- Fast design modifications ‚Äď Digital files allow for easy and quick adjustments.

- Less material waste ‚Äď Reduces the need for physical stencils, making the process eco-friendly.

Why is LDI important for PCB manufacturing?

The demand for compact, high-performance electronics continues to grow. LDI technology plays a crucial role in meeting these demands by allowing manufacturers to create complex circuit layouts with extreme accuracy.

Key Benefits of LDI in PCB Production:

- Fine-line circuit imaging ‚Äď Supports line widths as small as 50 microns or less.

- Better alignment precision ‚Äď Perfect for multilayer PCBs where layers must align perfectly.

- Faster turnaround time ‚Äď Since no photomasks are required, production cycles are shorter.

- Cost-effective for prototypes ‚Äď Ideal for low to medium-volume production runs.

- Reduces defects ‚Äď Eliminates common photolithography issues like misalignment and dust contamination.

What is LDI used for in PCB manufacturing?

LDI is especially valuable for:

- HDI PCBs ‚Äď Enables the creation of extremely fine pitch traces.

- Flexible & Rigid-Flex PCBs ‚Äď Ensures precise patterning for flexible circuits.

- RF and Microwave PCBs ‚Äď Delivers superior signal integrity in high-frequency applications.

- Prototyping & Small Batch Production ‚Äď Reduces the need for costly photomask production.

What are the steps in the laser imaging process?

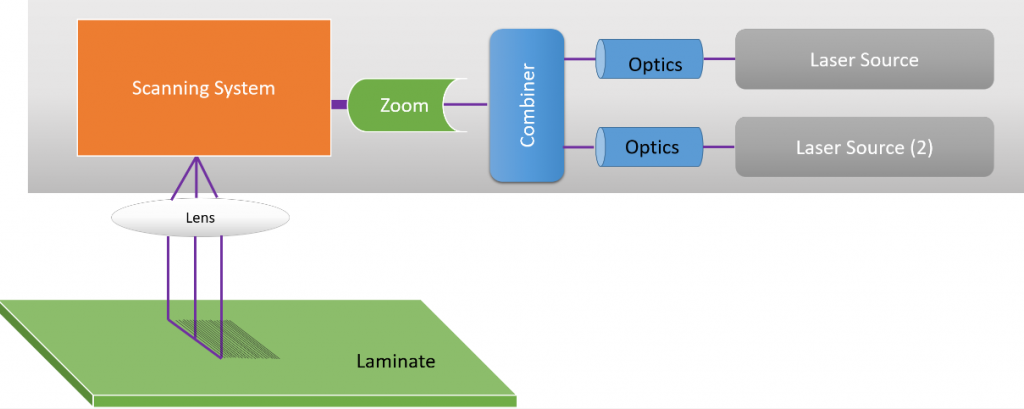

The LDI process follows a precise workflow to ensure accurate circuit patterning on the PCB. Here’s how it works:

- Pre-Processing & Design Preparation ‚Äď The PCB layout is converted into a digital file for LDI processing.

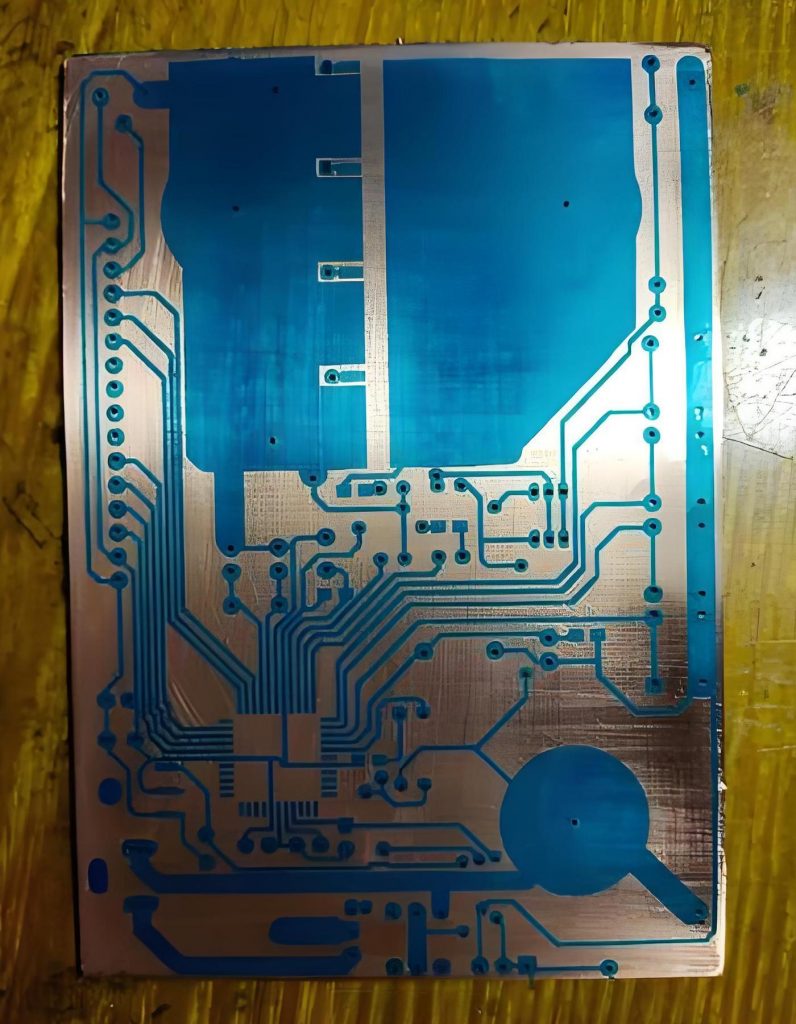

- Photoresist Application ‚Äď The PCB is coated with a light-sensitive photoresist layer.

- Laser Exposure ‚Äď High-precision UV lasers expose the design directly onto the photoresist.

- Development Process ‚Äď Unexposed photoresist is removed, revealing the circuit pattern.

- Etching & Stripping ‚Äď Unwanted copper is etched away, leaving the final circuit traces.

- Quality Inspection ‚Äď The board undergoes optical and electrical testing to ensure precision.

How does laser direct imaging work?

LDI uses a high-intensity laser beam to directly expose the photoresist layer on the PCB without needing a photomask. The system moves the laser precisely across the board, creating circuit traces based on a digitally stored layout.

Since the laser operates with pinpoint accuracy, it ensures perfect pattern alignment, making it especially useful for HDI and multilayer PCB manufacturing.

What are the advantages of laser direct imaging?

LDI has transformed the PCB manufacturing industry with its unmatched speed, accuracy, and efficiency.

1. Enhanced Precision

- Allows for narrow trace widths and tight spacing.

- Reduces alignment errors in multilayer PCBs.

- Supports the production of high-density circuit boards.

2. Eliminates Photomasks

- No need to create, store, or maintain expensive photomasks.

- Digital files can be easily modified for design updates.

3. Faster Production Cycles

- Reduces imaging time compared to traditional methods.

- Supports rapid prototyping and quick design changes.

4. Cost-Efficiency for Prototyping & Low-Volume Runs

- Ideal for custom PCB designs and small-batch production.

- Avoids high costs associated with mask creation.

5. Consistent & Reliable Results

- No photomask degradation means every board is identical.

- Reduces defects like overexposure, misalignment, and contamination.

What are the disadvantages of laser direct imaging?

Despite its benefits, LDI is not without challenges. Here are some considerations:

- 1. High Initial Investment: LDI equipment is more expensive than traditional imaging tools.

- 2. Higher Power Consumption: Laser systems require significant energy to operate efficiently.

- 3. Not Always Ideal for High-Volume Production: For very large-scale manufacturing, traditional photolithography may still be more cost-effective.

ConclusionÔľö

Laser Direct Imaging has revolutionized PCB manufacturing, offering higher accuracy, efficiency, and flexibility compared to traditional imaging techniques.

If you need precision-engineered PCBs with LDI technology, Best Technology is your trusted partner. Contact us at: sales@bestpcbs.com