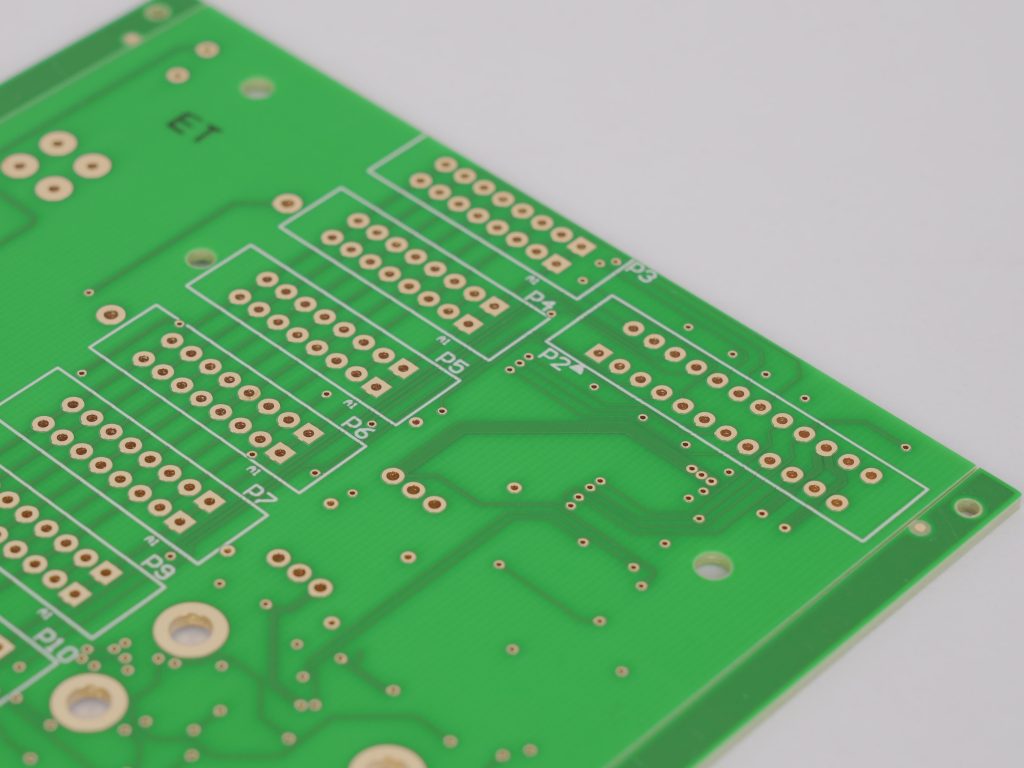

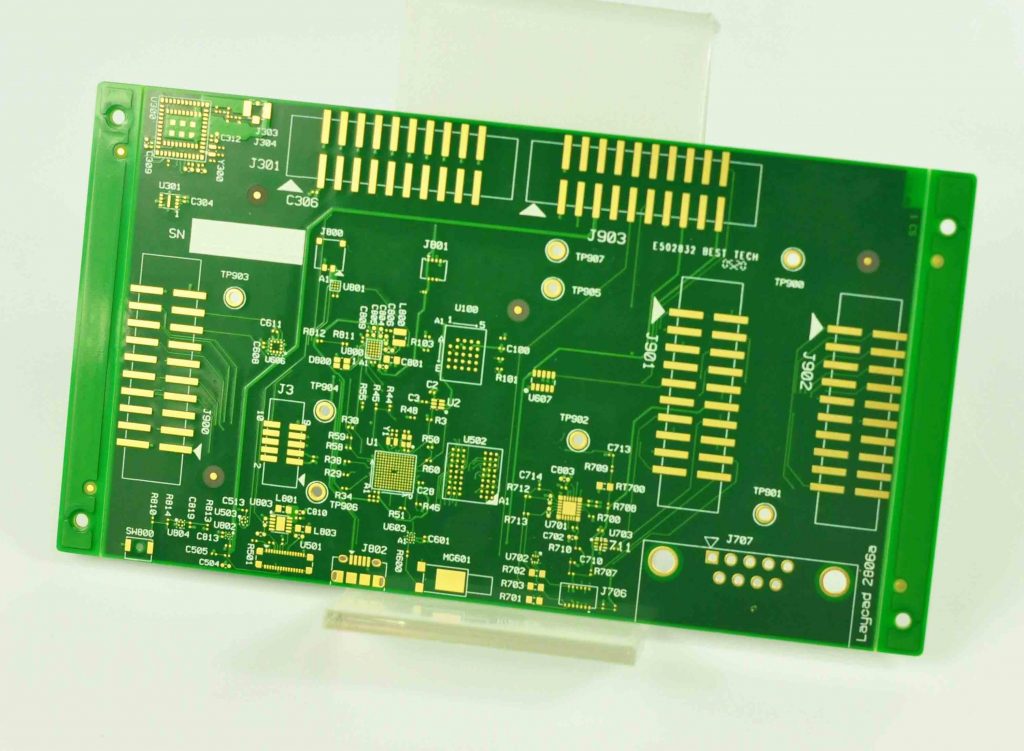

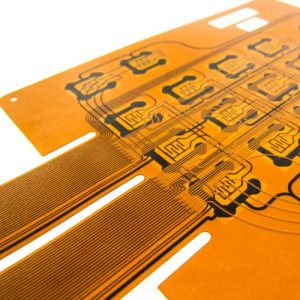

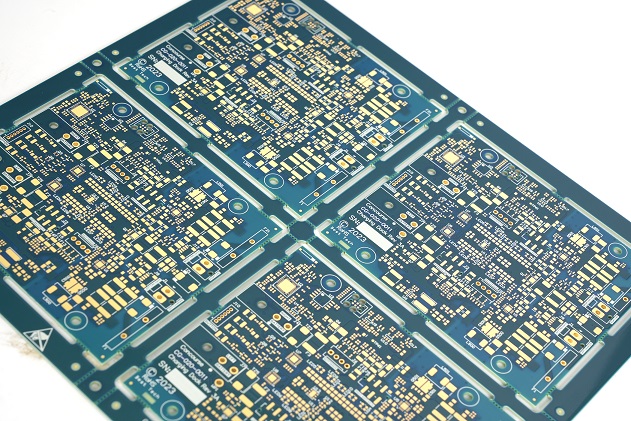

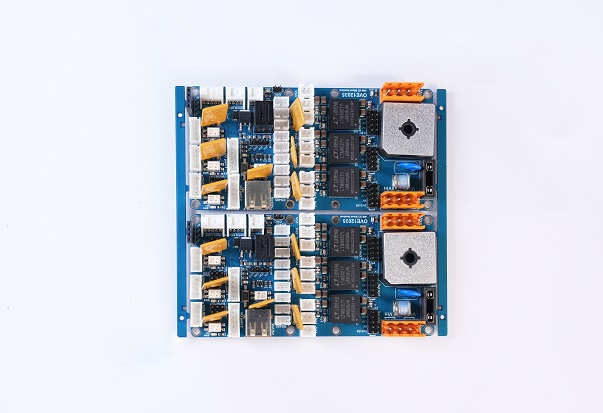

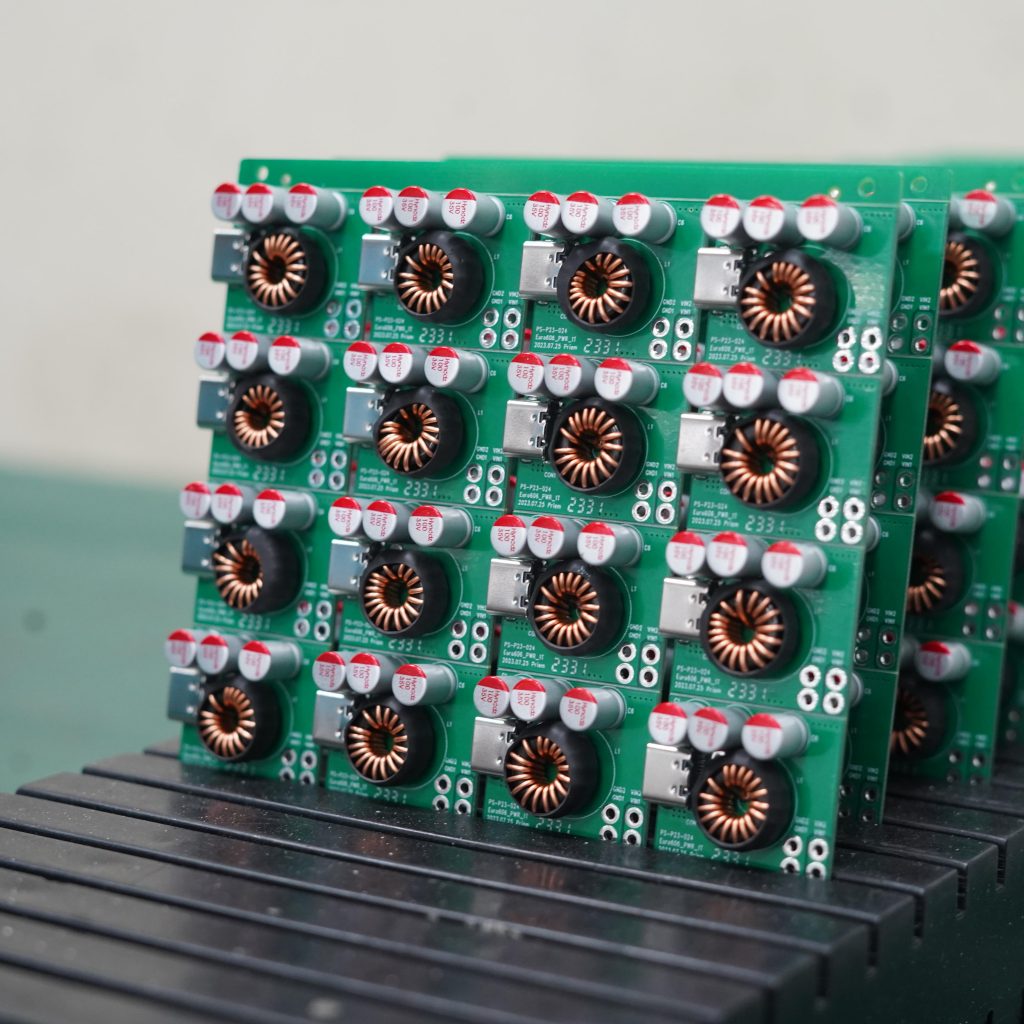

Surface mount technology (SMT) is a widely used surface assembly method in the electronic assembly industry. It mainly uses automated production equipment to directly solder surface mount components (SMD) to the pads on the surface of the printed circuit board (PCB). SMT has the advantages of high production efficiency, high space utilization, high density and miniaturization. However, it has high requirements for production equipment, processes and operating skills.

What is the surface mount technology process?

The process of surface mount technology (SMT) mainly includes the following steps:

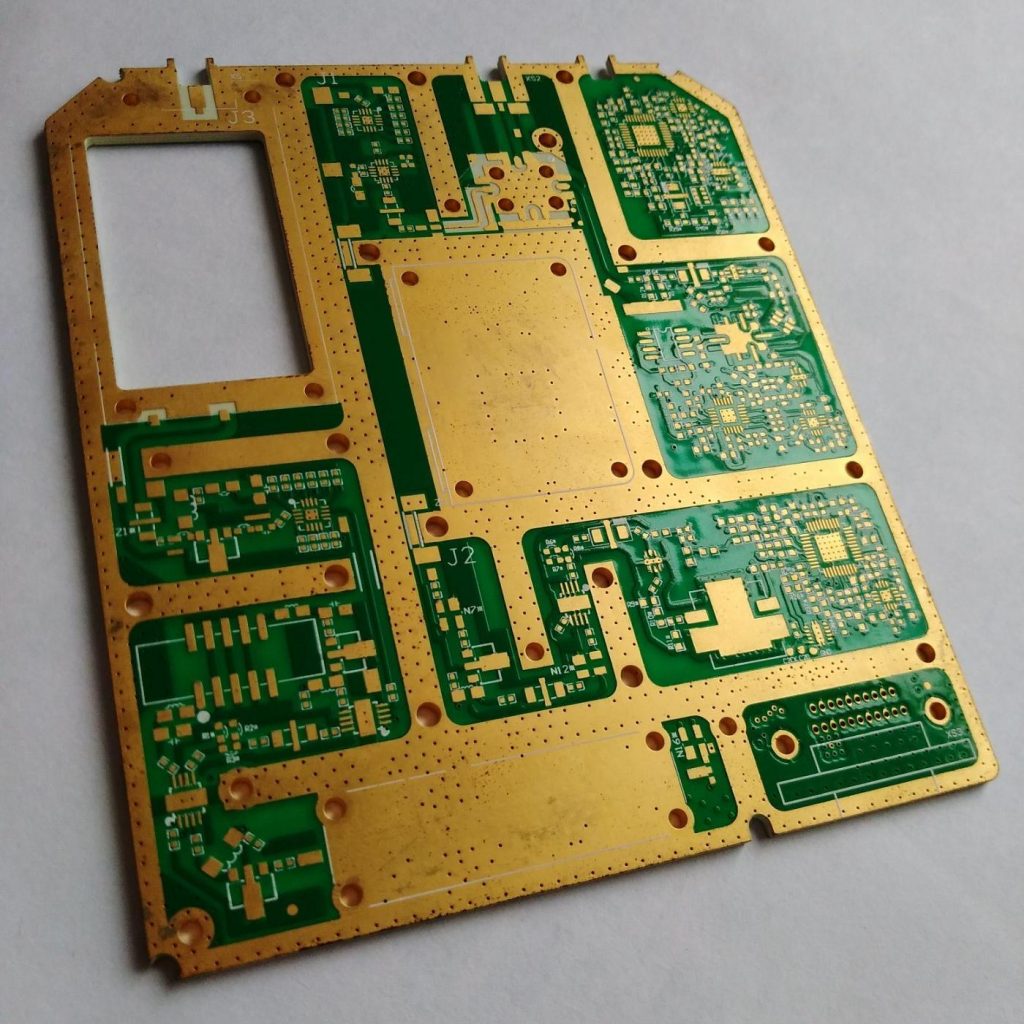

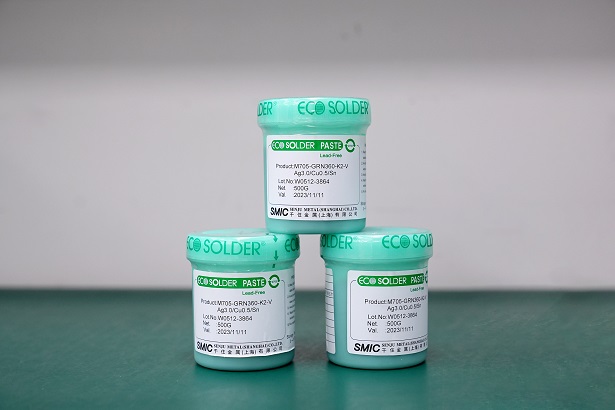

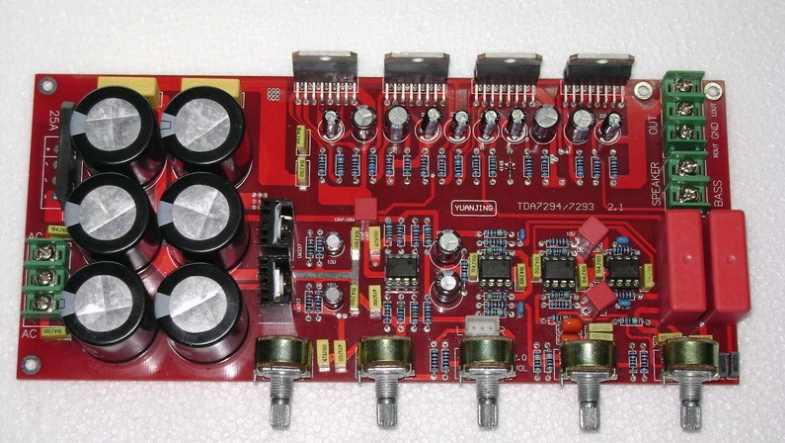

1. Printed circuit board preparation: Before surface mounting, the printed circuit board needs to be prepared first, including cleaning the circuit board, removing the surface oxide layer, and applying solder paste.

2. Component mounting: Use appropriate equipment to accurately mount various electronic components on the printed circuit board.

3. Soldering: After the components are mounted, the solder paste is heated to melt it to form a reliable welding connection.

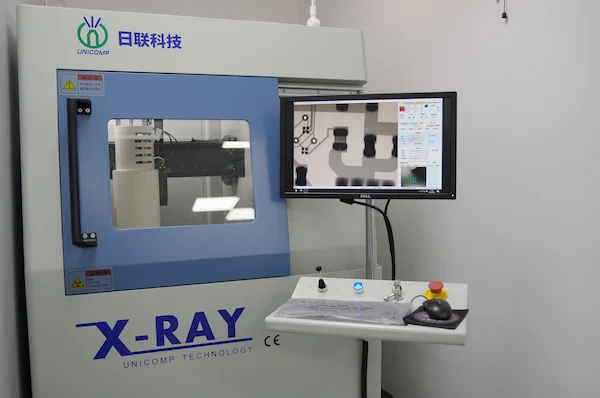

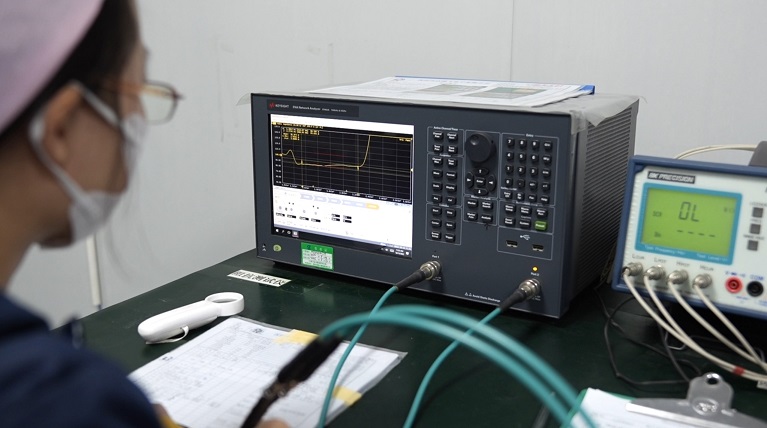

4. Inspection: After welding, use AOI for automatic inspection to ensure the correct mounting and welding quality of components.

5. Testing and debugging: Test and debug the mounted circuit board, and verify whether the function and performance of the circuit board meet the requirements through specific test equipment and procedures.

Each step needs to be carried out carefully to ensure that the mounted circuit board has good quality and reliability. In addition, surface mount technology is suitable for circuit board assembly, with the characteristics of compact structure and small size, and is widely used in the manufacture of electronic products.

What are the roles of surface mount?

The role of surface mount technology (SMT) is mainly reflected in improving the performance, reliability and production efficiency of electronic products, while reducing the volume and weight of products.

Surface mount technology (SMT) has the following significant effects:

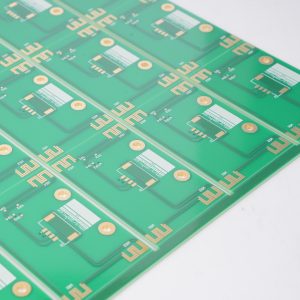

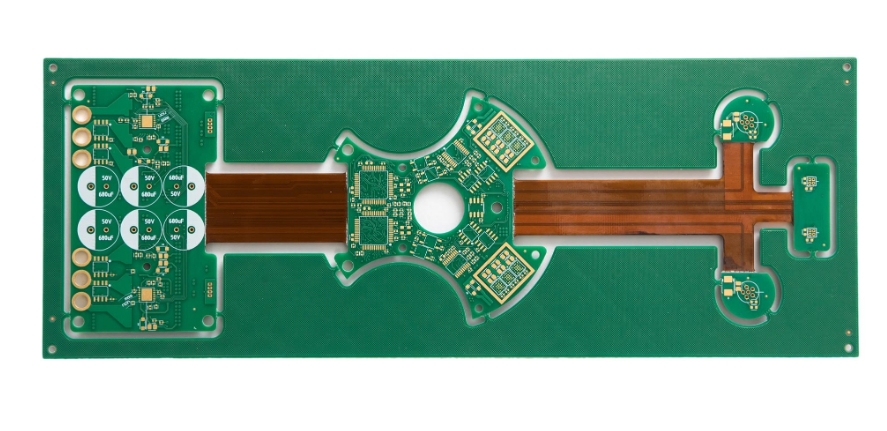

Increase assembly density and reduce product volume: By using surface mount technology, the volume of electronic products can be reduced by 40%~60% and the weight can be reduced by 60%~80%.

âImprove reliability: SMT has high reliability, low solder joint defect rate and strong vibration resistance.

Optimize high-frequency characteristics: SMT reduces electromagnetic and radio frequency interference and optimizes the high-frequency characteristics of the circuit.

Automated production: SMT is easy to automate, thereby improving production efficiency.

Enhanced compactness: Using small surface-mounted components can save a lot of space on the printed circuit board, and circuit assembly is easier to automate.

Adapt to a wide range of fields: As a new generation of electronic assembly technology, SMT has penetrated into various fields, including but not limited to computers, communication equipment, consumer electronics, etc.

In summary, surface mounting technology has significantly improved the comprehensive performance and production efficiency of modern electronic products by increasing assembly density, optimizing circuit performance, enhancing product reliability, and realizing automated production.

What is the advantage of surface mount?

The advantages of surface mounting mainly include:

High assembly density: Surface mounting technology (SMT) allows more electronic components to be installed in a limited space.

Small size and light weight of electronic products: By using SMT, smaller and lighter electronic products can be manufactured.

âHigh reliabilityâ: SMT has a low solder joint defect rate, which improves the reliability of the productâ.

âEasy to automateâ: SMT technology is very suitable for automated production and can greatly improve production efficiencyâ.

âDesign flexibilityâ: SMT allows different components to be used on the same circuit board, providing design flexibilityâ.

âEMC complianceâ: SMT technology helps meet electromagnetic compatibility (EMC) requirements and ensure the safety and performance of the equipmentâ.

âSelective solderingâ: SMT supports selective soldering, which increases the customizability of the productâ.

In addition, SMT technology is cost-effective because the packaging size of components is generally standardized and can be quickly and accurately installed using automated equipment, thereby reducing production costsâ. At the same time, SMT reduces human errors and improves product quality because the placement of components is very consistent, reducing errors or the need for rework.

What are the disadvantages of surface mount?

âThe disadvantages of surface mount technology (SMT) mainly include incompatibility with certain components, the possibility of soldering defects, and high equipment costs. â

âIncompatibility with certain componentsâ: SMT technology is not suitable for all types of components.

âPossibility of soldering defectsâ: Although SMT technology reduces the need for drilling and shortens setup time, it is not a zero-defect soldering process. In actual applications, SMT may encounter various soldering defects.

âHigher equipment costâ: Although SMT technology can improve production efficiency and circuit density, it requires expensive special equipment and professional technicians.

In summary, although SMT technology has many advantages, such as reducing drilling, shortening setup time, and improving production efficiency, it also has some disadvantages, especially in terms of incompatibility with certain components, possible soldering defects, and high equipment costs.

What does SMD stand for in surface mount?

SMD stands for Surface Mounted Devices. â

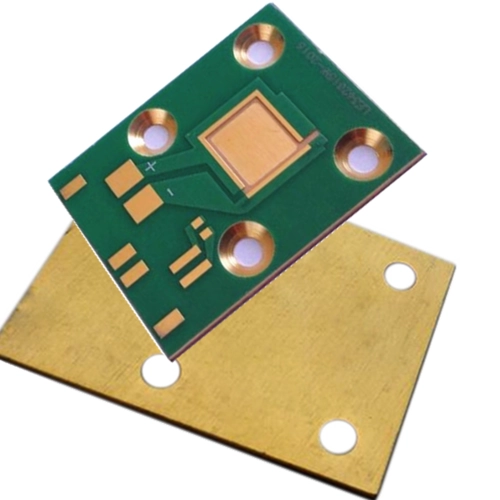

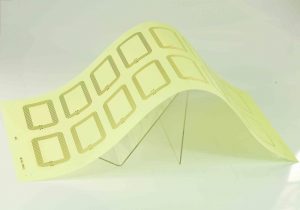

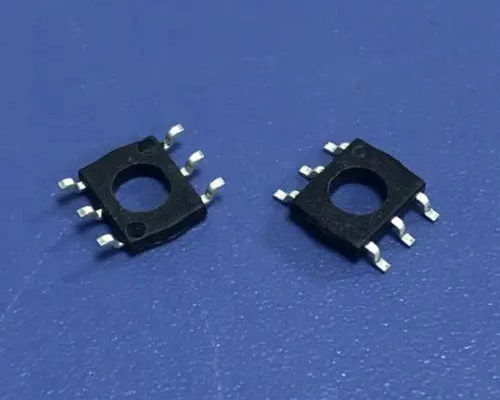

SMD is a type of component in surface mount technology (SMT), which is characterized by small size, high power, stable performance, and easy automated assembly.

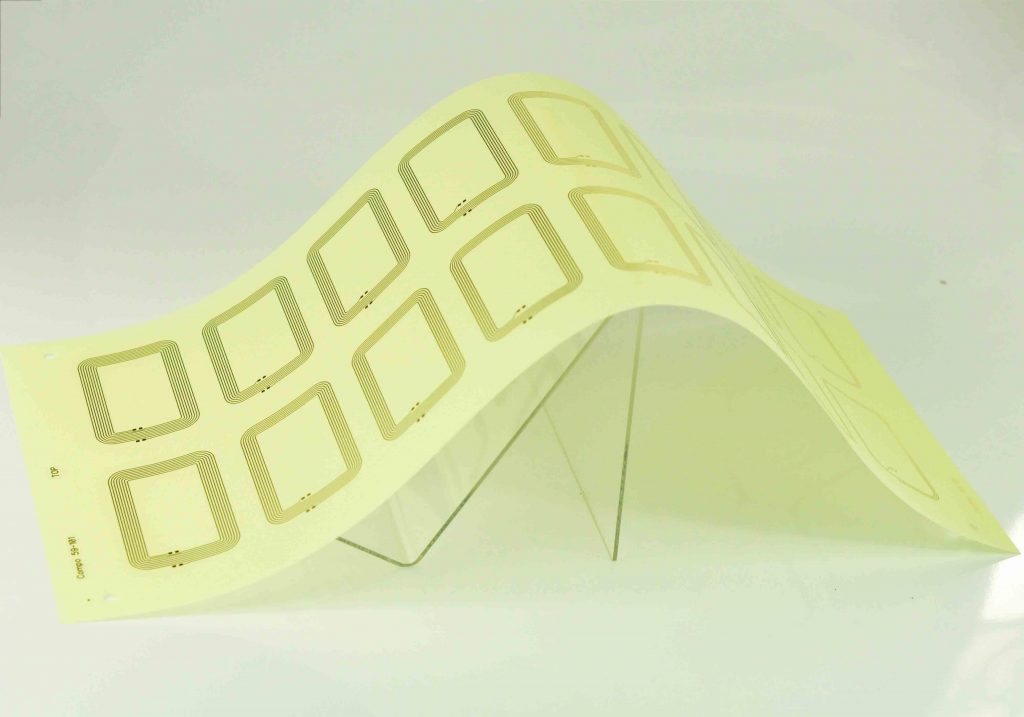

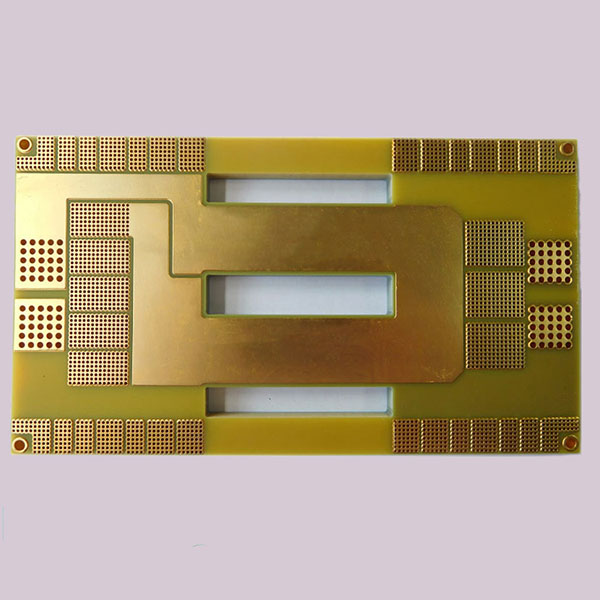

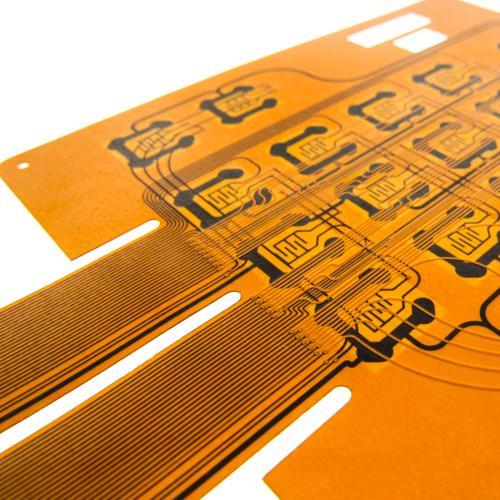

SMD packaging technology can maximize the space utilization on the circuit board, especially for the design of dense circuit boards. SMD packaging usually adopts metal oxide semiconductor (MOS) technology, and its packaging methods are diverse, including COB, QFN, LCC, BGA, etc.

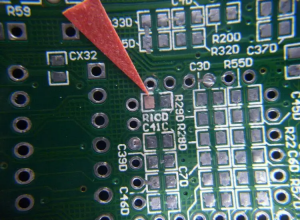

In practical applications, the appearance inspection of SMD devices includes visual inspection or use of a magnifying glass to check whether the solder end or pin surface is oxidized or has contaminants, and to ensure that the nominal value, specification, model, accuracy, and external dimensions of the components are consistent with the product process requirements. To ensure the performance and reliability of the device.

The wide application of SMD technology not only improves the performance of electronic products, but also promotes the automation and efficiency improvement of the electronics manufacturing industry. It is an indispensable part of the modern electronics manufacturing industry, especially in applications that require high integration and high reliability.

What is the application of surface mount?

The application of surface mount technology is mainly reflected in improving production efficiency, reducing product volume and weight, and meeting the market demand for miniaturized, lightweight, and high-performance electronic products. This technology is mainly used to mount electronic components on printed circuit boards (PCBs) to achieve circuit connection and system integration.

Surface mount technology can replace traditional through-hole insertion technology, thereby improving product reliability and performance and reducing costs. The technology has a wide range of applications, including but not limited to consumer electronics, military cutting-edge electronics, and fire detectors, manual alarms, and various electronic modules.

In the manufacture of electronic products, surface mount technology has become a revolutionary change, dominating the development of electronic equipment and bringing about major changes in electronic products.

Conclusion:

Usually, the electronic products we use are designed by PCB plus various capacitors, resistors and other electronic components according to the designed circuit diagram, so most electrical appliances require various SMT (patch) processing technologies to process.

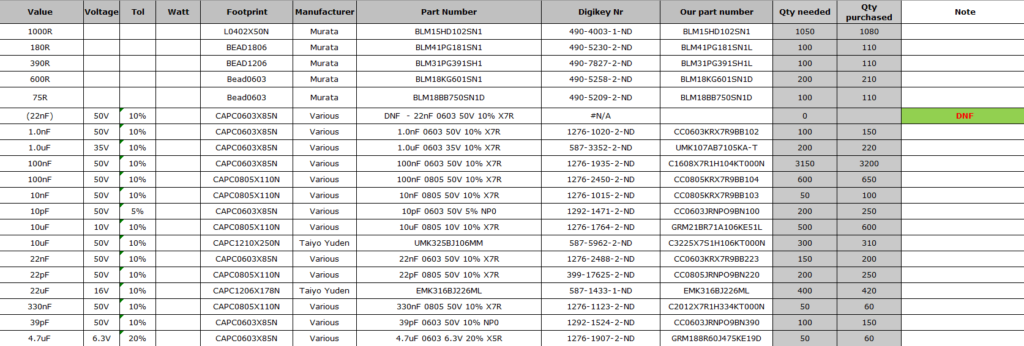

BEST Technology focuses on the procurement and processing of various electronic products and processing services for incoming materials, including but not limited to SMT patches, DIP plug-ins, welding, functional testing and maintenance, and assembly proofing and batch production. We can provide proofing, small batch and batch SMT mounting, and can also purchase electronic components and make PCBs.