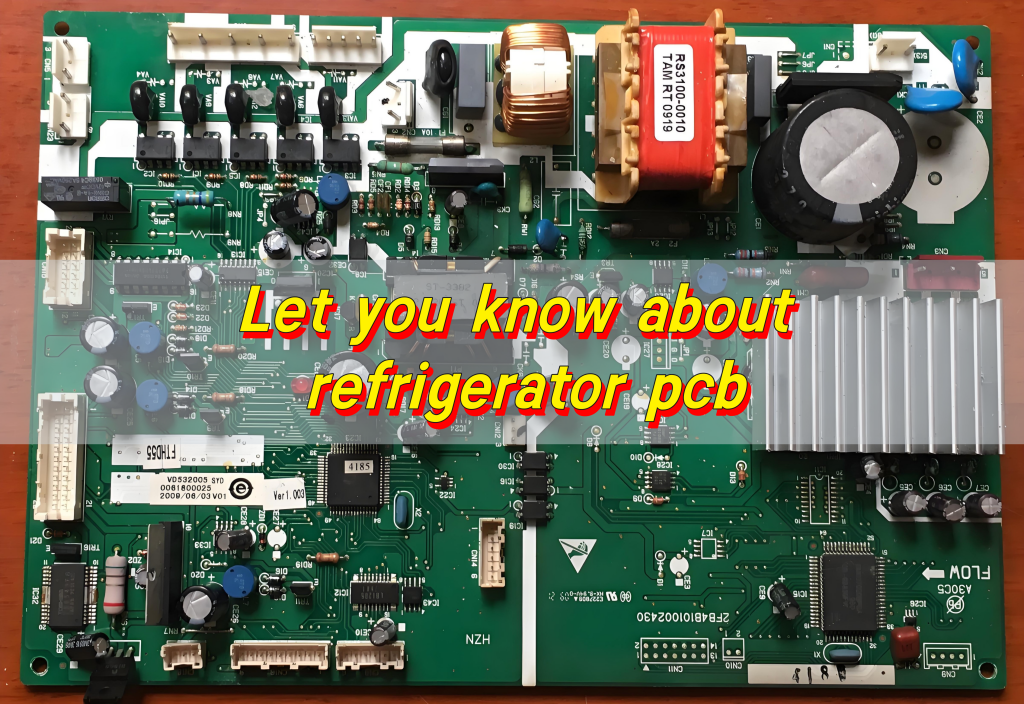

What is a refrigerator pcb? Refrigerator PCB is usually composed of insulating substrate, copper foil circuit and various electronic components. Insulating substrate provides support for circuits and components. Common materials include epoxy glass fiber board, which has good insulation performance, mechanical strength and stability, and can adapt to the complex environment inside the refrigerator.

Do refrigerators have PCBs?

There are PCBs inside refrigerators. The PCB of a refrigerator is one of the core control components of the refrigerator, usually called the computer version or control board of the refrigerator. It is responsible for controlling various functions of the refrigerator, such as refrigeration, preservation, energy saving, etc. It monitors and adjusts the operating status of the refrigerator in real time through sensors and control systems to ensure that the refrigerator can work efficiently and stably.

What is a PCB in a fridge?

The PCB in a refrigerator is an important part of the refrigerator control system. The role of PCB in a refrigerator mainly includes the following aspects:

- Connection and control: As the core of the refrigerator control system, PCB controls the switch and operation of the refrigerator by connecting various sensors and other electrical components. It integrates various sensors, such as temperature sensors and humidity sensors, to provide real-time feedback on the temperature and humidity conditions in the refrigerator, thereby achieving automatic control.

- Interactive function: PCB can interact with users through alarm lights, buzzers and displays to control various functions of the refrigerator, such as constant temperature, refrigeration and thawing.

- Intelligent function: For high-end refrigerators, PCB can also achieve more functions and information feedback by connecting to the Internet. For example, users can remotely control the refrigerator through mobile phone APP, set the laundry program in advance or let the sweeping robot start working, etc.

- Maintenance: In order to ensure the normal operation of PCB, it is necessary to clean and inspect it regularly, and ensure that its installation location is dry and ventilated to avoid moisture. In addition, avoid changing the temperature and appliance settings at will to avoid affecting automatic control.

What role do PCBs play in refrigerators?

The role of PCB in refrigerators mainly includes controlling various functions of refrigerators, processing sensor signals, realizing the interconnection of home appliances and improving the intelligence level of refrigerators.

1. Control various functions of refrigerators

PCB is one of the core control components of refrigerators, responsible for controlling various functions of refrigerators, such as refrigeration, preservation, energy saving, etc. Through sensors and control systems, PCB can monitor and adjust the operating status of refrigerators in real time to ensure that refrigerators can work efficiently and stably.

2. Processing sensor signals

PCB smart home appliance board is responsible for processing signals from various sensors, such as temperature sensors and humidity sensors in refrigerators. Through accurate analysis and processing of these signals, smart home appliance board can automatically adjust the operating status of home appliances according to preset programs.

3. Realize the interconnection of home appliances

PCB smart home appliance board also realizes the interconnection of home appliances. With the help of network module, smart home appliances can be connected to the home wireless network, and users can remotely control home appliances through mobile phone APP.

Can refrigerator PCB be repaired?

Refrigerator PCB (Printed Circuit Board) can be repaired. If the PCB of the refrigerator fails, you can take the following steps to repair it:

- Check the warranty period: First check whether the refrigerator is within the warranty period. If it is within the warranty period, you can contact after-sales for free repair or replacement.

- Self-inspection and simple repair: For some simple problems, you can check and repair them yourself. If the refrigerator does not run after power on, you can check whether the fuse, plug, temperature controller contacts, etc. are normal.

- Replace PCB: If the PCB is severely damaged, you may need to replace the entire PCB. You can buy an identical PCB to replace it yourself, but you need to be careful when disassembling it, especially not to damage other components.

What is the common damage of a refrigerator?

Common causes of refrigerator PCB damage mainly include the following:

- Overvoltage: The working voltage of the refrigerator circuit board is 220V. If the voltage is too high, the circuit board will be overloaded and damaged. It is recommended to use a socket with stable voltage or a voltage stabilizer to protect the circuit board.

- Overload: Hanging items on the refrigerator or placing heavy objects on its door will cause the door to be poorly sealed, air circulation to be blocked, and the refrigerator to work abnormally, which will lead to circuit board overload.

- Sudden power outage: Sudden power outage or lightning may cause damage to the refrigerator circuit board. In case of power outage or bad weather, it is recommended to disconnect the power supply or use a protective device.

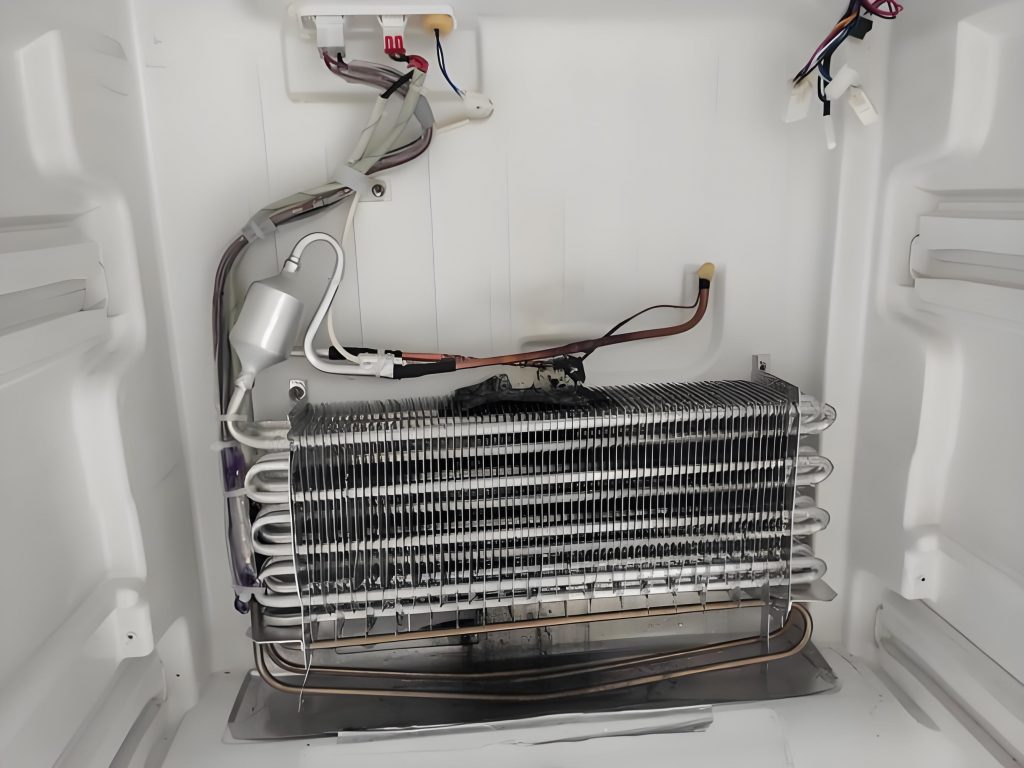

- Poor heat dissipation: The temperature of the refrigerator compressor continues to rise, and it cannot dissipate heat in time, which will burn out the fuse and other components, causing damage to the refrigerator circuit board.

- Unstable voltage: Unstable voltage cannot meet the power used by the refrigerator, which will cause damage to the refrigerator circuit board. It is recommended to install a voltage stabilizer to protect the circuit board.

How much does it cost to replace a circuit board in a refrigerator?

The cost of replacing a circuit board in a refrigerator is affected by many factors:

- Refrigerator brand and model: The design, function and complexity of the circuit board of refrigerators of different brands and models vary greatly, and the price will also vary greatly. The circuit boards of high-end brands or refrigerators with complex functions are usually more advanced, more sophisticated and more expensive.

- Fault severity: If only individual components on the circuit board are damaged, the problem can be solved by repairing and replacing the components, and the cost is relatively low; but if the circuit board has serious problems such as short circuits and burns, the entire circuit board needs to be replaced, and the cost will increase significantly.

How much does it cost to repair a PCB?

The cost of repairing a PCB is affected by many factors, as follows:

1. Fault type

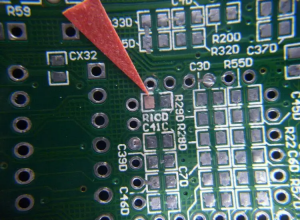

- Component damage: If only individual ordinary components are damaged, such as capacitors and resistors, the repair is relatively simple and the cost is low; if key components such as chips are damaged, the repair is difficult and the cost will increase significantly.

- Circuit problem: The difficulty of repairing a circuit break or short circuit varies depending on the complexity of the circuit. The cost of repairing a simple circuit is low, and the cost of repairing a circuit problem on a multi-layer board or high-density circuit board is high.

- Solder joint problem: It is relatively easy to repair the cold soldering and desoldering of a small number of solder joints, and the cost is not high; but if a large number of solder joints have problems or the solder joints are located in important parts such as chips, the repair cost will increase.

- Software failure: For the PCB boards of some smart devices, if there are software failures, professional software engineers are required to debug and repair them, which may increase the repair cost.

2. Circuit board type

- Computer motherboard: The repair of ordinary desktop computer motherboards is relatively common and easy, and the cost is average; while the notebook motherboard has high integration and complex structure, which is difficult to repair and the cost is usually high.

- Mobile phone motherboard: Mobile phone motherboards are small in size and highly integrated. Repair requires high-precision equipment and technology, and mobile phones are updated quickly. The repair costs of motherboards of different models vary greatly.

- Home appliance circuit boards: The circuit boards of common home appliances such as TVs, refrigerators, washing machines, etc. have relatively simple functions, and the repair costs are generally stable, but if they are circuit boards of high-end smart home appliances, the repair costs may be higher.

- Industrial control circuit boards: Industrial control circuit boards have extremely high requirements for stability and reliability, and usually use high-quality components and complex designs. They are difficult to repair and costly.

How to customize refrigerator PCB?

Customizing refrigerator PCB requires the following steps:

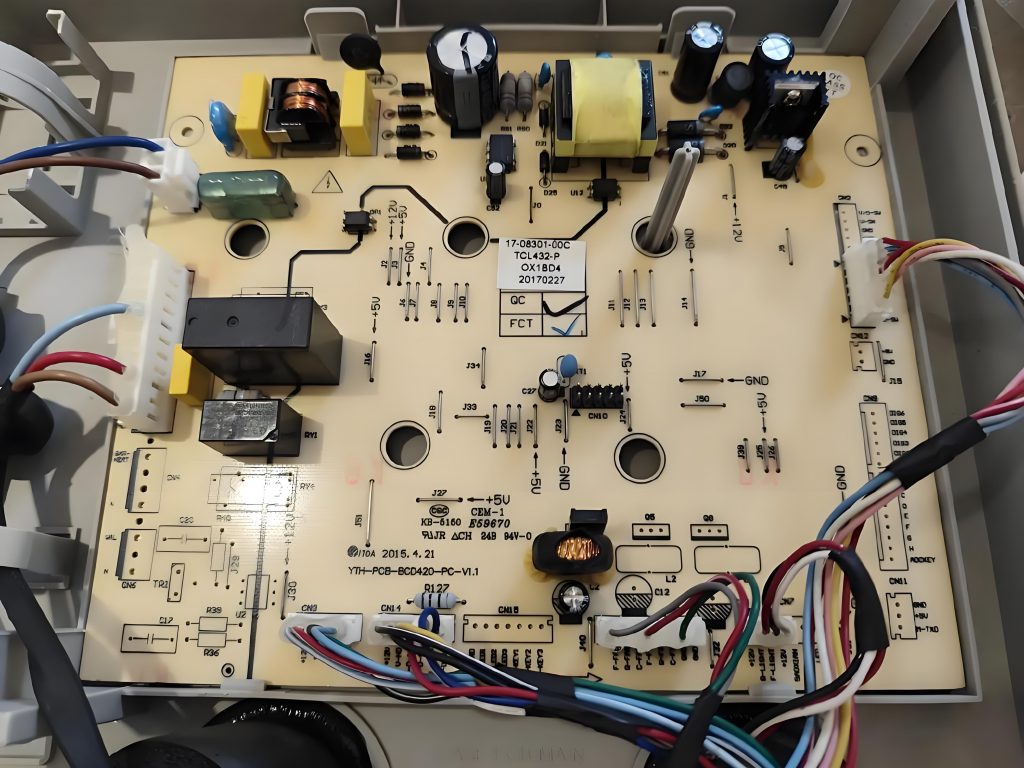

- Clear requirements: determine the functional requirements of the refrigerator, consider the use environment of the refrigerator, determine the PCB’s operating temperature range, humidity requirements, electromagnetic compatibility and other performance indicators.

- Design circuit: According to the requirements, use professional design software to draw circuit diagrams, layout and wiring; plan the board layers reasonably. For refrigerator PCBs with complex functions, multi-layer board design can be used; consider the heat dissipation problem. For heating components, they should be laid out as close to the edge as possible, and heat sinks or heat dissipation holes can be added to ensure the temperature stability of the PCB during operation.

- Select materials: According to the use environment and performance requirements of the refrigerator, select the appropriate substrate and the appropriate copper foil thickness to meet different current carrying capacity and signal transmission requirements. According to the electrical performance and environmental adaptability requirements, select the surface treatment process, etc.

- Manufacturing and testing: During the manufacturing process, drilling holes needs to be accurately drilled, electroplating ensures the formation of a good conductive layer, etching removes excess copper foil, silk-screens clear and accurate symbols and component identification, and uses automated optical inspection equipment to quickly and accurately inspect the PCB. Electrical and functional tests are also performed to ensure that the PCB meets the design requirements and performance standards.

- Assembly and debugging: Assemble electronic components onto the PCB through surface mount technology or through-hole technology, pay attention to welding quality, perform system debugging on the assembled PCB, check whether the various functions of the refrigerator are normally implemented, such as temperature control accuracy, start and stop and operation status of the refrigeration system, intelligent interconnection function, etc., and make timely adjustments and optimizations to any problems that arise.

As a key component of the refrigerator, the refrigerator PCB should be designed to take into account the special environment of the refrigerator, and be resistant to low temperature, humidity, and electromagnetic interference. BEST Technology will start from the design of the refrigerator PCB and customize the best solution based on the characteristics and needs of different refrigerators. In the production process, various process standards are strictly followed, and then the finished product is strictly tested to ensure the high quality of the PCB layer by layer.