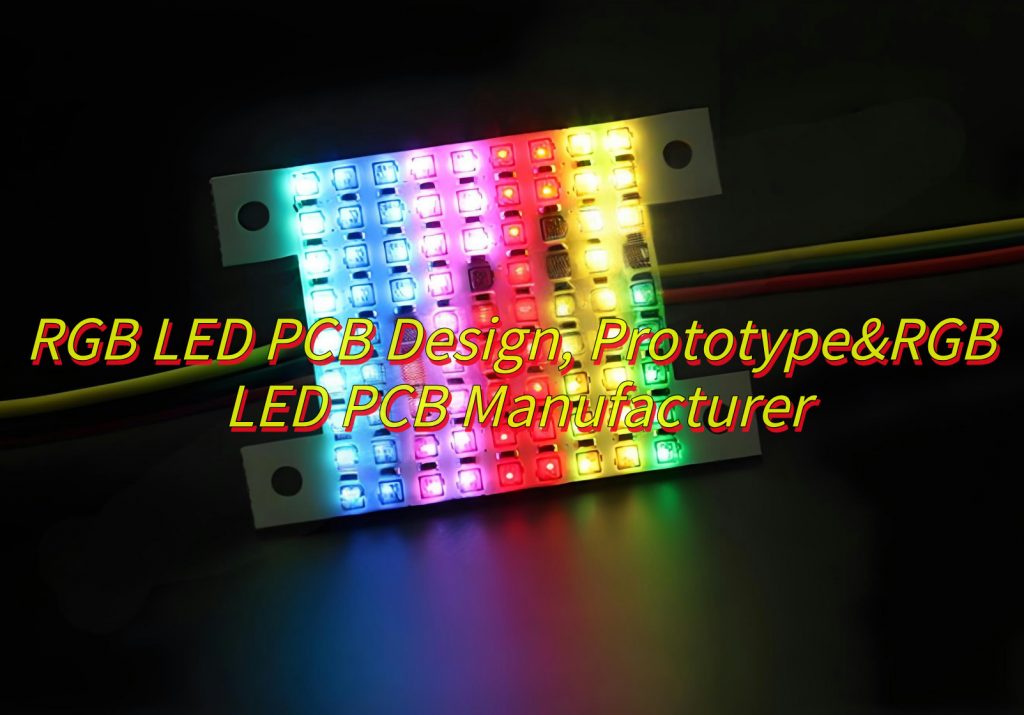

RGB LED PCB is an important part in modern lightening system, It can be seen everywhere in our lives, such as the breathing light strips of smart homes, dynamic special effects of stage lighting and so on. Would you like to get more information about RGB LED PCB? In this blog, letâs explore information about feature overview of RGB LED PCB , and how to design, how to select a PCB supplier together.

Best technology specialize in high quality RGB LED PCB design, prototype and manufacturing over 18 years. We provide one-stop PCB solutions services from signal integrity optimization, thermal management simulation to dynamic heat dissipation of aluminum substrates. And we support PWM precise dimming protocol, integrated EMC protection and impedance matching design. It can ensure 24-bit color restoration accuracy. We can meet the strict demands of stage lighting, architectural lighting, and smart home fields for full-color LED PCBs, helping you seamlessly transition from optical design to mass production. If youâre interested in our service, welcome to contact us at sales@bestpcbs.com.

What Is RGB LED PCB?

RGB LED PCBÂ is a type of printed circuit board (PCB) that integrates Red, Green, and Blue LEDs. It achieves a wide variety of color effects by mixing the light of these three colors (the primary colors of light) and is commonly used in lighting, decoration, and display devices.

What Are the Advantages of RGB LED PCB Board?

- Excellent heat dissipation performance– Adopting aluminum substrate design and suitable for high-power RGB LED applications

- âPrecise color control and diversity-supports dynamic gradient and breathing light and can mix a million of colors.

- âHigh integration and design flexibility-â integrate multiple RGB LEDs, driver chips and control circuits and support modular design

- âEnergy saving and environmental protection– 80% energy saving compared to traditional light sourcesâ and adopt recyclable aluminum substrate and LED does not contain harmful mercury.

- âHigh reliability and stability-âresistant to high temperature, moisture and impact, and can adapt to complex environments (such as outdoor display screens and industrial equipment).

- âFast response and dynamic performance-â LED response speed reaches nanoseconds, and with high-speed PCB signal transmission, smooth dynamic effects (such as game lighting synchronization) can be achieved.

- âWide application scenarios-â decorative lighting (ambient lighting, advertising screens), electronic equipment (keyboard backlight), industrial indication and so on.

Advantages of RGB LED PCB Board

What Is the Use of LED RGB PCB board?

- Decorative lighting– Ambient lighting, holiday decorative lights, dynamic color gradient, breathing lights, music-synchronized lighting effects.

- âElectronic equipment-â Keyboard backlight, computer case lighting effects, status indication of  mobile phones/headphones, personalized lighting feedback of mouse, monitor.

- âDisplay and advertising–Â âLED large screen(stage, shopping mall, stadium), full-color dynamic display of billboards and signboards.

- âIndustrial and signal indication -â Equipment status indicator (operation/fault/warning) and multi-color prompts for traffic signals and security systems.

- âSmart home -ceiling lights, table lamps with adjustable color temperature/color.

- âArt and entertainment–Â âStage lighting, art installations, interactive light shows, background light adjustment for movies/studios.

- âAutomotive lighting-â Interior atmosphere lights, chassis lights.

What Is the Use of LED RGB PCB board?

RGB LED PCB Manufacturers

Selecting the right RGB LED PCB manufacturer ensures high-quality PCBs for efficient LED performance. Reputable manufacturers provide design support, high-precision manufacturing, and customized solutions. Best Technology, a leading PCB manufacturer, offers expert engineering services and high-quality RGB LED PCBs tailored to specific applications. Here are more information about our company:

- Technology leadership-Utilizes aluminum-based board with high-precision Surface Mounted Technology(SMT) , supporting monochrome/full-color RGB solutions.

- One stop PCB solution:Â provide a wide range of RGB LED PCBs (including RGB LED strip PCB ) and matching electronic components, such as RGB LEDÂ driver PCB and RGB LEDÂ controller PCB.

- Customized Solutions-Provide customized service( including custom logo) with low MOQ( one piece)

- Quick Respond to Customers-Professional team online 24 hours, providing full process tracking from scheme design to prototyping and mass production.

- Fast Delivery-Have a electronic manufacturing supply chain, providing one-stop solutions and PCBA services.

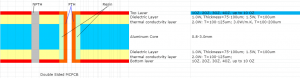

What Are the Materials of RGB LED light PCB?

- Aluminum substrate– Suitable for high-power RGB LED scenarios (outdoor displays, wall washers).

- FR4 board – Suitable for low-cost, low-power solutions (advertising light boxes, indoor decorative lights).

- Flexible substrate (PI base material) : Suitable for bendable scenarios (LED strip lights, curved decorations).

- Copper substrate– Suitable for high-power precision equipment (industrial equipment, high current modules).

- Double-sided fully fiberglass PCB board-Suitable for high stability scenarios (commercial lighting, moisture resistance requirements).

Materials of RGB LED light PCB

How To Design RGB LED PCB?

1. Select LED and drive solution â

âLED modelâ: Prioritize models with integrated driver IC (such as WS2812B) to reduce peripheral circuits.

Diver Mode: Low power suitable for Direct MCU PWM drive (such as Arduino). High power suitable for Constant current driver chip (such as TLC5940) or MOSFET+resistor.

âInterface typeâ: Determine common anode or common cathode, and unify circuit logic.

â2. Circuit schematic design â

âPower inputâ: Indicate voltage (5V/12V/24V) and maximum current.

Series control: short signal line + data flow direction mark (such as DINâDOUT of WS2812B).

Parallel control: independent PWM signal line grouping.

âFilter designâ: Add capacitor (10ÎŒF~100ÎŒF) to the power supply end, and add RC filter (100Ω+100pF) to the signal line.

â3. PCB layout planningâ

âLED arrangementâ: uniform spacing (avoid light spots), high-power LED spacing â„10mm. Close to the edge of the PCB (reduce heat impact on sensitive components).

âComponent partitioningâ: the power module is away from the signal line. The MCU/driver chip is centrally arranged to shorten the signal path.

â4. Power and ground wiringâ

âPower lineâ: line width â„1mm/1A current, avoid right-angle routing.

âGround copper layingâ: full board laying to reduce noise and impedance.

âSingle-point groundingâ: digital ground, analog ground, and power ground are connected through 0Ω resistors or magnetic beads.

â5. Signal line optimizationâ

âSignal priorityâ: high-frequency signals (such as PWM) are given priority to short and straight routing.

Avoid parallel long-distance power lines (anti-interference).

âImpedance controlâ: add termination resistors (22~100Ω) when necessary.

â6. Add test and debug interfaceâ

âPower test pointâ: VCC and GND reserved pads or through holes.

âSignal test pointâ: Key PWM signal lines are led out to the pin header.

âReserve jumper next to LEDâ: Convenient for disconnection detection in case of fault.

â7. Silkscreen and markingâ

âPolarity markâ: All LEDs are marked with “+” or “-” poles.

âInterface markingâ: Clearly define the position of power, signal, and ground wires (such as “VIN”, “DIN”, “GND”).

âVersion numberâ: The version is marked in the corner of the PCB (such as V1.0).

â8. DRC rule checkâ

âLine width/spacingâ: Comply with PCB factory process (for example: minimum line width 0.2mm, spacing 0.15mm).

âShort circuit/open circuitâ: EDA tool automatically checks (such as KiCad, EasyEDA).

âHeat dissipation verificationâ: Ensure that there are no dense traces in high-power areas.

â9. Prototyping and test verification

âAfter you made a RGB LED PCB prototype, you can do some functional and heat tests with it.

âColor switching: Check whether the RGB mixing is normal.

Brightness consistency: Measure the voltage/current of each LED.

âHeat testâ: Run continuously for 1 hour in a high-power scenario and measure the temperature rise (recommended â€60â)

FAQs of RGB LED PCB

- What is the lifespan of an RGB LED PCB?

RGB LED PCBs can last over 50,000 hours, depending on heat management and component quality.

- Can RGB LED PCB be customized?

Yes, RGB LED PCBs can be customized in terms of size, shape, and control features based on application needs.

- What is the difference between RGB LED FR4 PCB and RGB LED aluminum PCB?

RGB LED aluminum PCB offer better heat dissipation, while RGB LED FR4 PCB are more cost-effective and suitable for low-power LEDs.

- How do I control the colors in an RGB LED PCB?

Colors are controlled using PWM (Pulse Width Modulation) technology via an LED driver or microcontroller.

- Where can I buy high-quality RGB LED PCBs?

Best Technology provides high-quality RGB LED PCBs with expert design and manufacturing services.

In conclusion, thatâs all about RGB LED PCB. If you want to know more about RGB LED PCB design, prototype and production, please feel free to contact Best Technology.(The email is at the beginning of this blog). Looking forward to hearing from you soon!