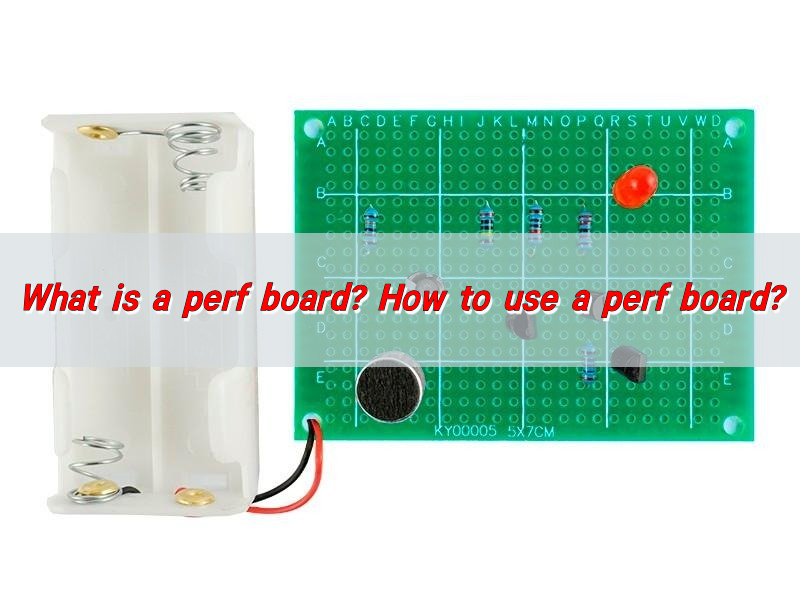

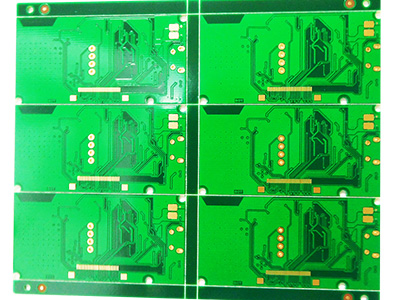

Perf board is a board used in the field of electronics and PCB. It is a board with grid holes. These holes are used to insert and solder the pins of electronic components and are used to place and solder electronic components. It is similar to a breadboard, but is mainly used in situations where soldering is required, and is suitable for simple circuit design and prototyping.

What is a Perf Board?

A perf board, short for perforated board, is a flat board with a grid of holes. These holes are plated or non-plated, allowing electronic components to be mounted and soldered.

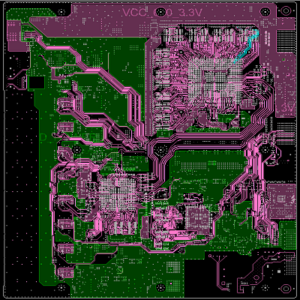

Unlike a PCB, which has pre-designed traces, a perf board gives complete freedom to create custom wiring connections.

Perf boards are ideal for prototyping and small-scale projects. They serve as an intermediate step between breadboarding and full PCB manufacturing. Many electronics enthusiasts rely on perf boards to refine their designs before moving to mass production.

What Does a Perf Board Do?

A perf board acts as a platform for circuit assembly. It allows components like resistors, capacitors, and integrated circuits (ICs) to be mounted securely. By connecting these components using solder and wires, a functional electronic circuit is created.

Unlike a breadboard, which is temporary, a perf board provides a permanent and durable solution. Once components are soldered, they remain firmly in place, ensuring a stable connection and reliable performance.

What is the Difference Between a Perf Board and a Breadboard?

Both perf boards and breadboards are used for building circuits, but they serve different purposes.

Breadboards are reusable, allowing circuits to be assembled without soldering. They are great for testing ideas but are not ideal for permanent designs.

Perf boards require soldering but create stronger and more reliable connections. They are used when a project needs to be more durable than a breadboard prototype.

Breadboards have internal metal connections, making wiring easy. Perf boards require manual wiring, offering complete customization.

How Do Perf Boards Work?

A perf board works by providing a physical base for electronic components. Each hole allows component leads to pass through. Solder is used to create permanent electrical connections.

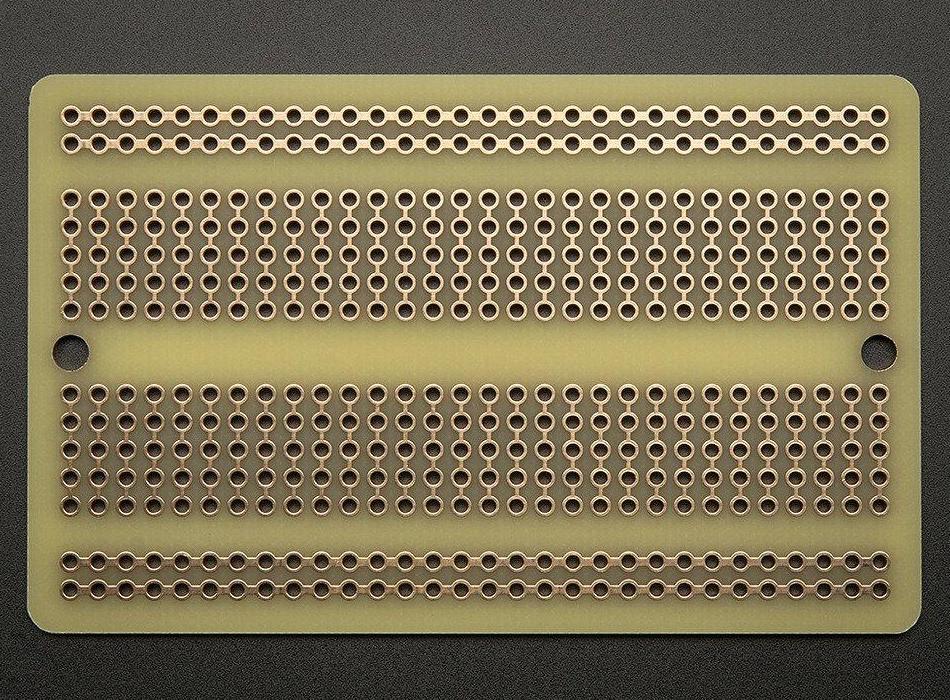

There are different types of perf boards:

Single-sided perf boards have copper pads on one side for easy soldering.

Double-sided perf boards have pads on both sides, enabling more complex connections.

Stripboard perf boards have connected rows of copper, simplifying circuit routing.

Since there are no predefined traces, wiring must be done manually using solder bridges, jumper wires, or thin copper wires. Proper planning helps prevent messy connections and improves circuit performance.

How to use a perf board?

Using a perforated board (also known as a hole board or a universal board) to build a circuit requires welding to connect components. Its operation process is essentially different from that of a breadboard.

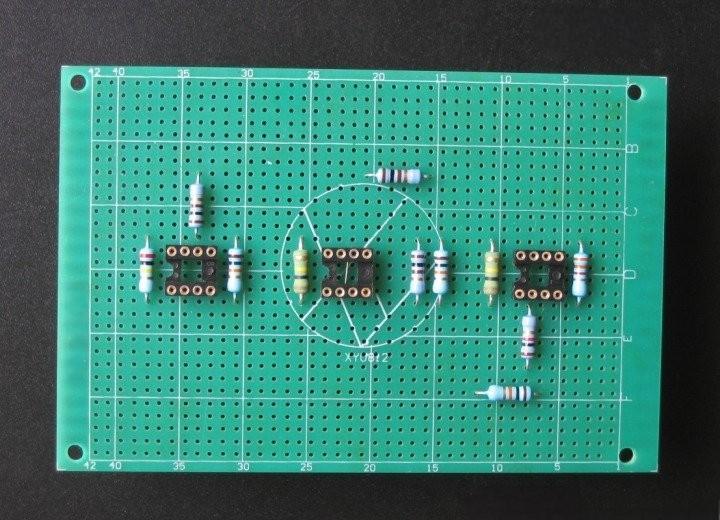

First, you need to plan the component layout according to the circuit diagram, insert the component pins into the corresponding holes, pay attention to polarity and spacing, and ensure that components such as integrated circuits, resistors, and capacitors are arranged neatly. When laying out, the wire length should be shortened as much as possible, and the component pins themselves can be used as connection points to simplify welding.

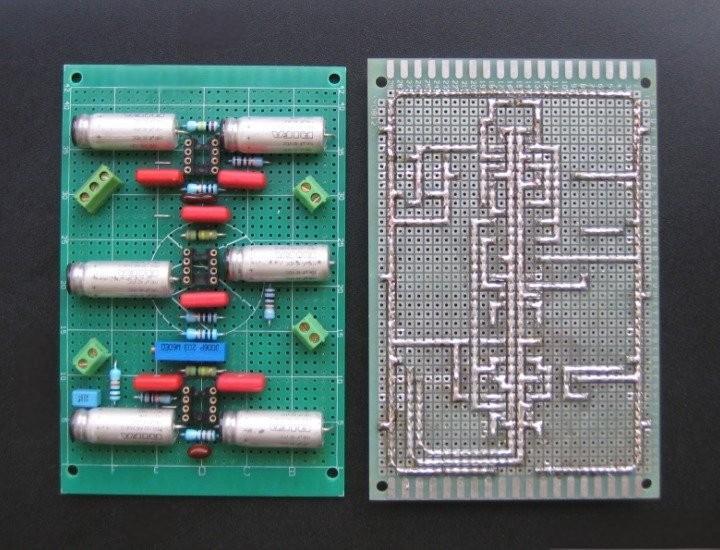

Next, you need to use solder to weld the component pins to the copper foil surface of the perforated board. Before welding, you need to clean the oxide on the surface of the copper foil, and use rosin flux to improve the welding quality.

For jumper wires, you can choose thin enameled wires or tinned copper wires, and weld them along the copper foil routing direction. If necessary, you can use wires to connect different areas on the back of the board. After welding, you need to cut off the excess pins of the component, and use a multimeter to check whether each solder joint is conductive to confirm that there is no short circuit or cold soldering.

To increase the success rate, you can draw a perforated board layout diagram on paper in advance, marking the component positions and routing paths. For complex circuits, modular welding can be used to test functions part by part. Beginners are advised to use a soldering station instead of a soldering iron to control the temperature and prevent damage to components.

In addition, the copper foil surface of the perforated board should be kept clean, and excessive solder accumulation should be avoided during soldering, which may cause short circuits in adjacent copper foils. The completed circuit can be fixed in the housing with screws, which is suitable for making electronic devices that need to be used for a long time.

What is a Perf Board Made Of?

Perf boards are made from different materials, depending on durability and cost requirements.

- FR4 (Fiberglass): Strong and heat-resistant, commonly used for professional projects.

- Phenolic Resin: Cheaper but more fragile, suitable for low-cost applications.

- Epoxy Boards: Lightweight and flexible, but less durable than FR4.

The copper pads on perf boards can be tin-plated for better solder adhesion. Some high-quality boards have gold-plated pads, offering better conductivity and corrosion resistance.

How to Make a Perf Board?

Creating a perf board from scratch requires precision. The board must have evenly spaced holes and strong material for durability.

Manufacturers follow these steps:

- Material Selection – FR4, phenolic, or epoxy sheets are chosen based on the application.

- Hole Drilling – A grid of evenly spaced holes is drilled using CNC machines.

- Copper Plating (Optional) – Some boards are coated with copper to improve conductivity.

- Cutting and Finishing – The board is trimmed to standard sizes and inspected for defects.

For DIY projects, modifying an existing board is easier than making one from raw materials.

How to Cut a Perf Board?

Cutting a perf board requires precision to avoid damaging the holes or copper pads. The best methods include:

- Score and Snap – Using a sharp knife, score the board along a straight line, then snap it carefully.

- Hacksaw or Rotary Tool – A fine-tooth saw or Dremel cuts through thick boards easily.

- Shears – Heavy-duty scissors work for thinner boards but may cause rough edges.

After cutting, sanding the edges ensures a smooth finish. It prevents sharp corners from damaging wires or components.

How to Assemble Electronic Components on a Perf Board?

Building a circuit on a perf board follows a structured process:

- Plan the Layout – Arrange components logically to minimize wire clutter.

- Insert Components – Place resistors, capacitors, ICs, and other parts into the holes.

- Solder the Connections – Secure each component with solder, ensuring strong joints.

- Add Wires or Solder Bridges – Use insulated wires or solder traces to connect components.

- Test the Circuit – Check for short circuits or missing connections before finalizing.

Good soldering techniques prevent weak joints and ensure a long-lasting circuit. Proper planning and clean wiring improve circuit performance.

Conclusion:

A perf board is an essential tool for prototyping and DIY electronics. It bridges the gap between temporary breadboards and professional PCBs. For high-quality custom perf boards, contact sales@bestpcbs.com