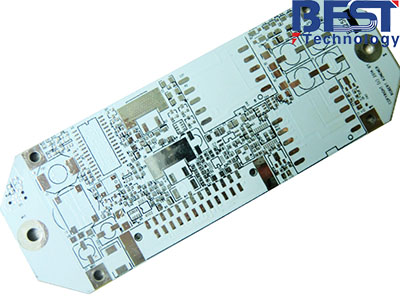

Best Technology is a full turn-key assembly service company, we can supply the assembled board with very nice and clean surface.

Do you want to know how we control the cleaning process of PCBA? We would like to share the full cleaning process.

As we know, flux is used when soldering electrical components to a printed circuit board.

After assembly process finished, we need to remove all the unnecessary flux paste or other solder flux/ residue in order to avoid any quality issue.

Although it is a simple work, but to prepare some tools and preparation is necessary and important. Like wash board water, dust-free cloth, brush,Tweezers, static bracelets, finger gloves

Here is the how the cleaning process we made:

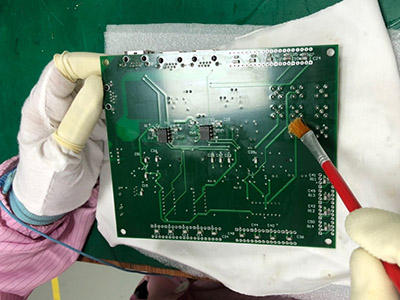

Step1:

Use brush to brush the solder joint and solder flux on the soldered PCB. Applying some alcohol or acetone onto the brush, do not use too much pressure, as this may cause the solder point to break. Repeat the procedure as necessary, to remove remaining flux residue on the PCBA.

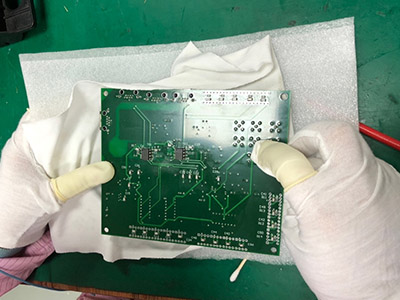

Step2:

Wipe with a clean dust-free cloth to clean the assembled PCB.

Keep board clean and tidy to make sure no impurities and finger marks. Do the same process for bottom side.

Step3:

When above step finished, keep the board for an extra day to let the board dry enough before packing. Best QC guys will do final inspection for the finger prints under light. this will be helpful to check the cleaning result further.

Step4:

Finally, use dust-free cloth to do the final cleaning and let the board dry and clean enough before package.

Above are the process for how we clean the assembled boards.

Best Tech is a very professional manufacturer in printed circuit board and assembly. We clean each of assembled boards as the procedure we showed above.

If you are interesting to know more process for how we control the quality for the PCB assembled boards, contact us at any time, we will show you more.