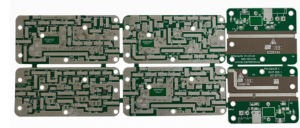

DCB is abbreviation of Direct Bonding Copper. It is an electrical composites with high thermal conductivity and high dielectric strength. Which formed by the copper foil and the ceramic substrate suffering high temperature melting and diffusion process in an inert gas. In power electronics industry, the DCB promoted module package chip interconnect technology development and stimulate power electronics products towards on high power density, multi-set, high-performance low-cost.

The advantage of DCB PCB:

- the copper foil and ceramic can be bonded directly, which have good thermal conductivity, usually thermal conductivity of aluminum -DBC is 24 ~ 28 W / (m K), AlN-DBC is 170 ~ 220 W / (m · K).

- The stability of ceramic substrate makes DCB has a very excellent insulation properties under various conditions.

- Coefficient of thermal expansion close to the silicon enables semiconductor chip which soldered on board to avoid the stress caused by temperature changes, therefore can greatly extend the life of semiconductor products.

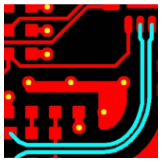

- Can process all types of graphics and lines like PCB, and strong current conducting capabilities make it easy to achieve board-on-chip interconnection function, the maximum carrying capacity will be up to 100 amps / millimeter.

The application of DCB

- Energy-saving control of appliances.

- Energy-saving control of industrial electrical.

- The transportation of wind, solar and other new energy.

- New type solar panels.

Parameters of DCB

| Name | Unit | Test Conditions | Parameters |

| Insulation resistance | MΩ | ≥1 | |

| Insulation voltage | VAC(.RMS) | 1min | ≥3000 |

| Tensile strength | kN/cm2 | ≥5 | |

| Peel strength | N/mm | ≥6 | |

| Thermal conductivity | W/m.k | Indoor 20℃ | 24~28 |

| Thermal expansion coefficient | 1×10-6/℃ | 50~200℃ | ≤7.4 |

| Adaptable of temperature range | ℃ | -40~+200 | |

| Hydrogen embrittlement temperature | ℃ | 400 |

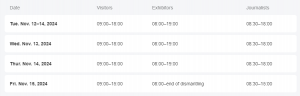

The flatness tolerance value of DCB

| DCB diagonal Length L (mm) | 200~250 | 150~200 | 110~150 | 80~110 | 60~80 | 40~60 | 20~40 | <20 |

| Tolerance value (mm) | ≤1.0 | ≤0.8 | ≤0.6 | ≤0.4 | ≤0.2 | ≤0.1 | ≤0.05 | ≤0.03 |

Parameters of ceramic substrate

| Name | Unit | Test Conditions | Parameters |

| Al2O3 content | % | ≥96 | |

| Insulation voltage | kV/mm | ≥12 | |

| Permittivity | 25℃ 1MHz | ≥9.2 | |

| The dielectric loss tangent | 25℃ 1MHz | ≤3×10-4 | |

| Thermal conductivity | W/m.k | Indoor 20℃ | ≥22 |

| Thermal expansion coefficient | 1×10-6/℃ | 20℃~500℃ | ≤6.7 |

| Density | g/cm3 | ≤3.7 |