It is quite a hot day Aug 9th, 2018. We have our nice UK customers visit us on such hot day. That’s really appreciated.

Both of them are very easygoing, we started to discuss the capability to manufacturing the 14 Layer PCB, customer were concern the impedance control well as well as other specification on the board such as the thickness of the immersion gold. Except FR4 PCB, We also showed other kinds PCB we made to customer, such as Rigid-flex circuit, FPC, metal core PCB, Ceramic PCB , as well as some  special PCB,  Heavy copper PCB,  High Tg PCB,  PCB assembly products.

- Picture1:Best-Technology-Meeting-room

After a short meeting in our office, we bring customer to see our PCB Manufacturing Production Line.

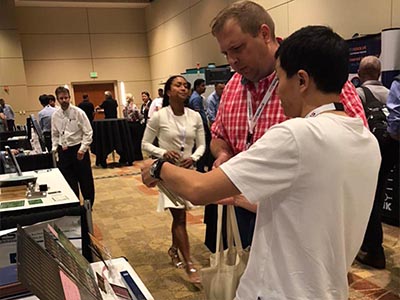

Firstly we showed customer our different Tests Equipment including Impedance Tester, Copper Thickness Tester, Gold thickness Tester, etc.

- Picture2:Tester-Equipments

And then we bring customer to see the different process for how to make the PCB.

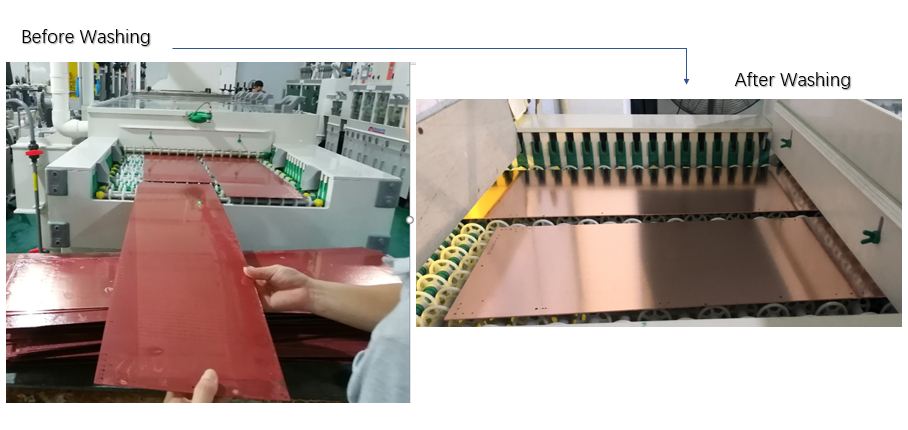

Developing Process

- Picture3:Developing-Process

Drilling Process

- Picture4:Drilling

E-Testing Process

- Picture5:E-testing

After that, we go to our QA line to showing customer how we do the board inspection before we send out the PCB to our customers.

- Picture6:QA-process

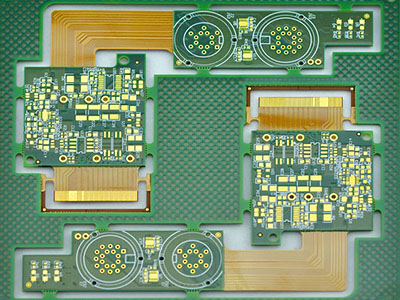

Customer was very happy and satisfy with everything they see in our PCB Plant.

- Picture7:Photos-in-Best-Technology-office

Wish next time we’ll have chance to have lunch or dinner with customer to talk more.