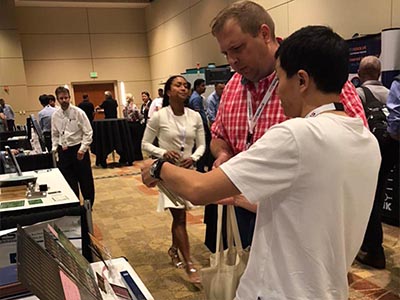

Glasses, watch, T-shirt etc. all these little things in our daily life are changed by wearable. There’s been a veritable explosion of the Internet of Things (IoT) wearable. Apple just  few weeks ago got FDA clearance for its ECG functionality on the Apple Watch. Many companies are looking to make their mark on the wearable industry.

Taking the smart glasses as an example, it is able to find a right direction for you or you can use it to have a facetime with friends. In the near future, it will be a kind of mobile product as smart phone. Even there is no need to go to the hospital for a electrocardiogram examination and ask some suggestions from the doctor, because the smart watch will make it happen. In a word, if you can dream it, the rigid-flex PCB will make it.

There are so many wearable devices springing up as bamboo shoots after a spring rain and the electronic market growth is led by these wearable devices. Meanwhile, they also bring a huge market for the rigid-flex PCB.

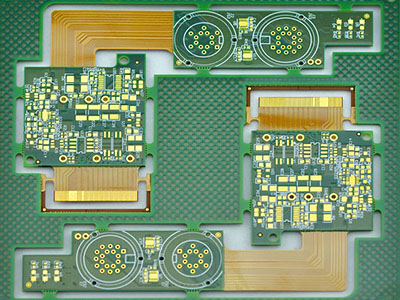

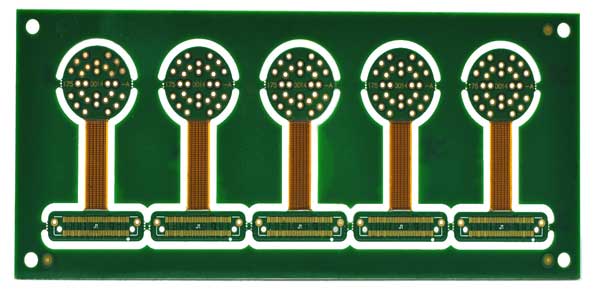

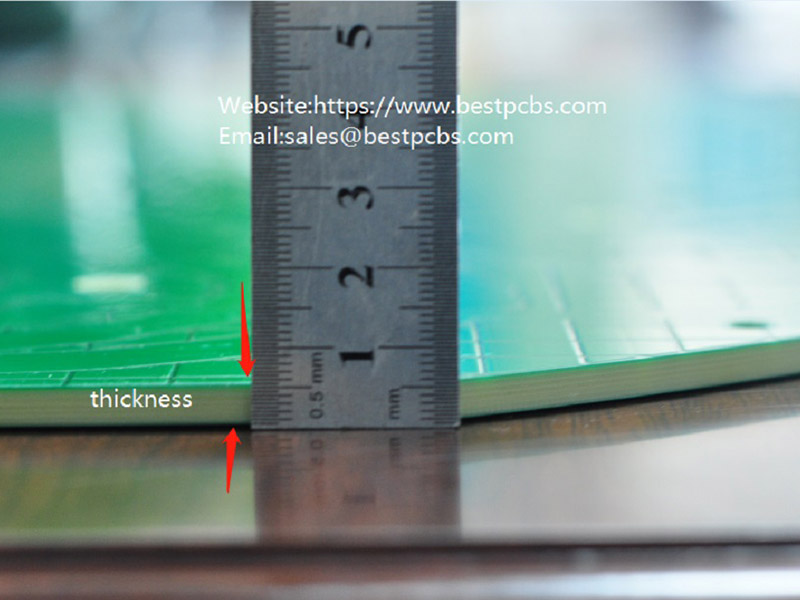

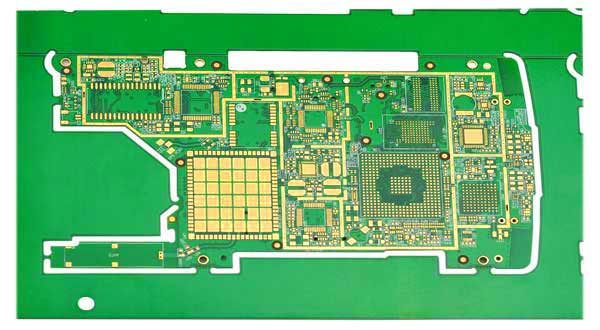

Rigid-flex PCB stands for the combination of rigid PCB and flexible PCB which is gone through lamination and other process flows to form a board that possesses characteristics of FPC (flexible printed circuit) and PCB (printed circuit board). It can be applied to some products those have special requirements because of it has a certain area of flexibility and rigidity. With this characteristic, it is really helpful to reduce space, volume and performance of the product. Therefore, the rigid-flex PCB is mainly used in consumer electronics. The products in North America and Europe are dominated by military and medical device. Nowadays, the production area of rigid-flex PCB is concentrated in Europe, America and Japan. Besides, the rigid-flex PCB, which replaces the combination of rigid-flexible-connector, is mainly applied to mobile phone.

Because of all these benefits of rigid-flex PCB, believe that it will be the darling of the crowds after HDI and FPC.