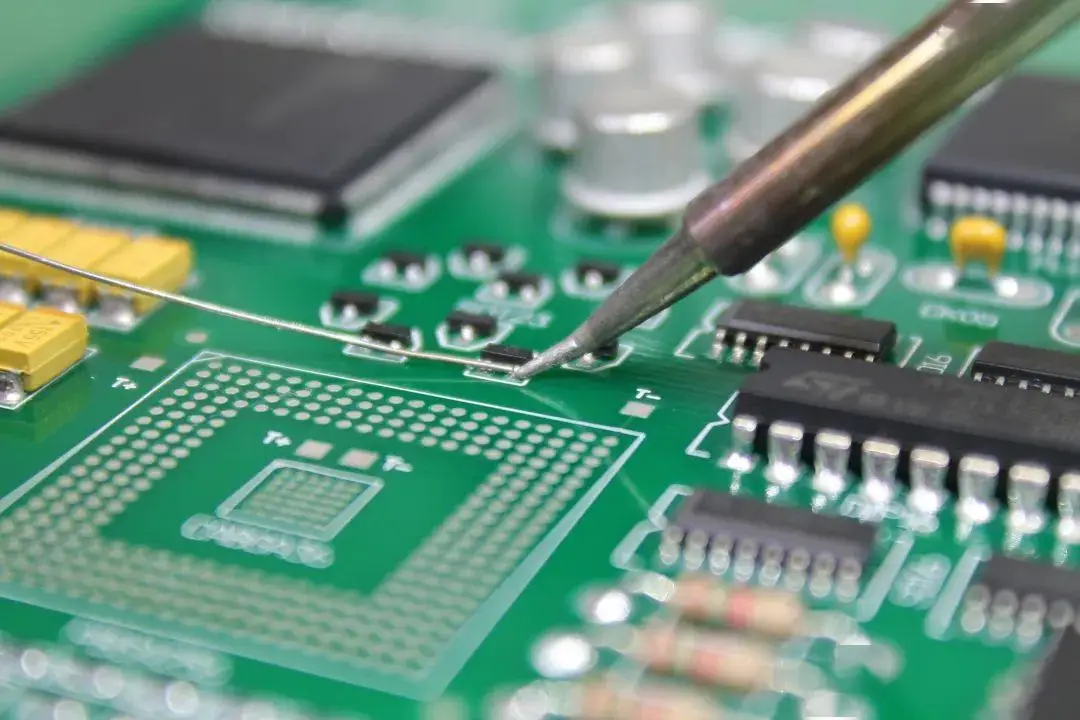

Printed circuit board assembly(SMT), also known as “stuffing†or “populatingâ€Â the bare printed circuit board, is quite an intricate process which involves many different stages. Best Technology’ in house printed circuit board assembly service makes ordering your turnkey printed circuit boards a hassle-free experience as you can count on the industry’s largest support team to help you control every step of the process.

Here are some of the basic elements involved in the printed circuit board assembly process:

Solder Paste – Solder paste is a combination of flux, a chemical created to assist in the bonding and melting of the metal, and small fragments of metal (solder) so as to apply the electronic components to the printed circuit board. The paste is placed on the board in specific places along the board in exact amounts with the use of a Solder Stencil and a paste application machine, automatically.

Pick and Place Machine – This machine is essential in an automated printed circuit board assembly process. The machine is programmed to automatically coordinate with complete accuracy the places to precisely mount each electronic component to be soldered to the printed circuit board. These machines are exact and quick.

Infrared Reflow – After the precise bonding element (solder paste) is applied to the PCB, the board will be directed to the reflow oven to join the electronic components to the board by melting the solder paste. This “oven†is comprised of many heaters whose main function is to heat the board to a precise temperature and control the level of cooldown as the solder hardens. This process is crucial to the creation of properly functioning electronics. The printed circuit board will run through a series of testing to ensure no issues or short-circuiting nor misalignments have occurred.