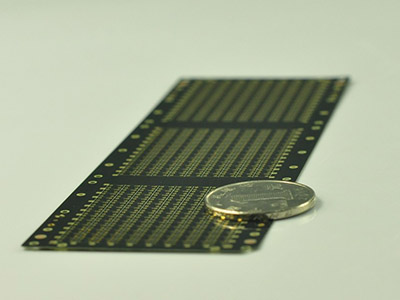

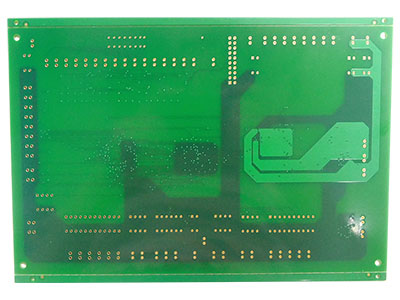

As we know, the extra thin PCB means the thickness of printed circuit board is more thin than normal PCB, which is refer to a thickness smaller than 0.4mm for 1L/ 2L & 4L PCB. For extra thin PCB, we know they are all very thin and are easily to be broken, so the option for the surface treatment of the extra thin PCB is very crucial.

So, what kind of finishing to be recommended for the extra thin Rigid PCB?

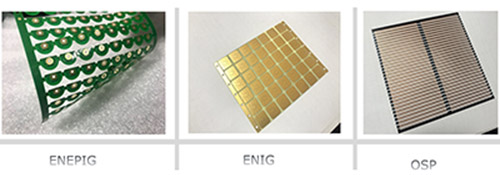

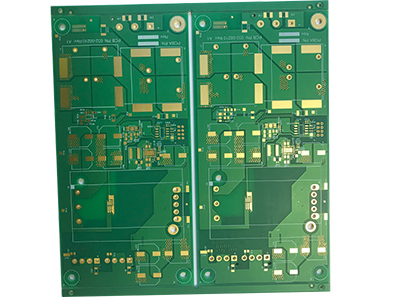

Generally, there are 3 kinds finishing can be recommended for the extra thin PCB. It is OSP, ENIG (Electroless Nickel Immersion Gold), and ENEPIG.

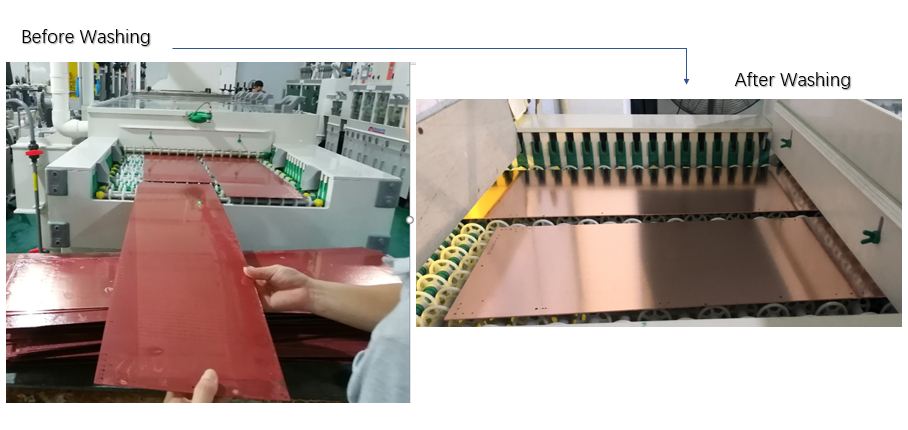

But you may want to ask that lead-free Tin is also a common finishing for the PCB. Why not recommend LF HASL?

Thatââ¬â¢s because while LF HASL Process, the PCB will be easy to be blew away, people will use heated compressed air to leveling (blowing) on the coating molten tin (lead) solder, during this process, the traces will be easy to be broken as well.

So normally, we will not recommend the LF HASL finishing for an ultra thin FR4 PCB.

HASL lead-free is only suitable for a board with minimum thickness of 0.6mm, while the standard gold immersion surface coating can support PCB with a minimum thickness of 0.2mm. For the surface treatment of ENEPIG , which plate only needs to be about 0.1 microns for palladium and about 0.1 microns for gold, (palladium is a precious metal that is much harder than gold), so for board with ENEPIG finishing, its surface will looks more smooth, thatââ¬â¢s also why it is the most recommended surface treatment for an extra thin PCB.

If you are searching for an extra thin PCB, feel freely to ask or send your inquiry to us. We will be pleased to share you more information regarding the extra thin PCB.

Tags: extra thin pcb, extra thin rigd pcb, surface treatment