If we observe carefully, we will find that most of the high-quality surface light lamps in the market use COB light source, such as LED spotlights, Automotive, LED Backlight for LED TV, etc. What are the advantages of such choice?

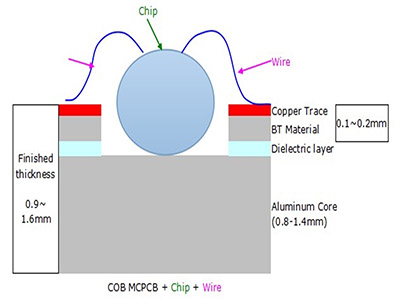

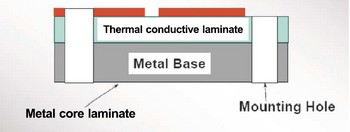

First of all, we need to how the COB differ from the common MCPCB. “Chip-On-Board” Metal Core PCB is a type of MCPCB used in thermoelectric separation application. By using COB, the micro-chip (also known as “die”) directly touch the metal core where the heat dissipate, and electrically interconnect the trace of circuit board (wire-bonding) so that power supply can be provided.

Advantages of utilizing COB MCPCB over common MCPCB:

- High thermal conductivity(137W/m.K), High insulation, High pressure resistance

- High reflectivity: mirror aluminum≥98% (The reflectivity of Taiyo Soldermask used in common MCPCB is 75-80%, the highest is only 90%)

Since the COB is packaged directly on the MCPCB, it’s easy assembly for high powers LED, direct heat dissipation through the substrate can not only reduce the manufacturing process and cost of the bracket, but also have the advantage of reducing heat dissipation resistance. So the spotlight produced by COB technology will be lighter, more flexible and able to realize more possibilities on the stage.

If you are also interested in COB, please feel free to contact me, I’m looking forward to communicating more with you.

You’re welcome to visit our website to learn more about us. https://www.bestpcbs.com/products/COB-MCPCB.htm