As we know, there are all kinds of ceramic PCB, DPC ceramic PCB, DBC ceramic PCB, LTCC ceramic PCB, HTCC ceramic PCB, thick film/thin film ceramic PCB.

Very few people know that there is AMB (Active Metal Bonding) ceramic PCB.

Do you know what’s the advantage for AMB ceramic PCB compare with other ceramic PCB (Al2O3/AlN/BeO/Si3N4 PCB)?

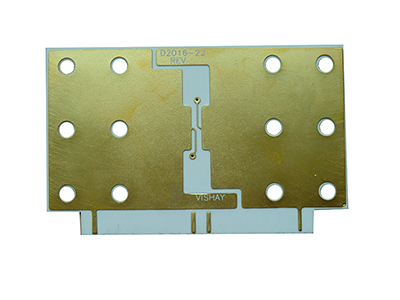

For AMB PCB, the substrate can be AlN ( Aluminium Nitride) and Si3N4 (Silicon Nitride) normally, AlN is the most popular. It is widely known that AlN with very high thermal conductivity ( Theoretical Value is 320W/m.k).

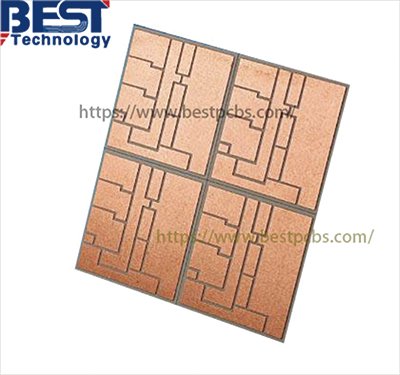

Using AMB technology to combine the oxygen-free copper and AlN material under high temperature, AlN with smaller thermal resistance, lower coefficient of thermal expansion and more stable partial discharge capability.

Compared with the traditional DBC or other substrate, the Aluminum Nitride copper-clad ceramic substrate made by the AMB technology with higher bonding strength of the copper layer and better cold and hot cycling characteristics.

So it is widely used in the field of IGBT, especially for the high-power device control module.

AMB with competitive price and the copper thickness can be much thicker.

For more details, please contact me sales@bestpcbs.com

I will update the manufacture process at the end of this month.

Tags: ceramic PCB, DBC ceramic PCB