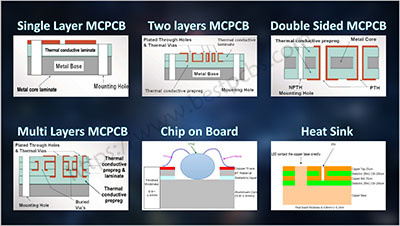

Best Technology has more than 14 year experience for producing Metal core PCB, we have our own raw materials factory for MCPCB and we fabricate MCPCB in Shenzhen, so that customer various special requirements can be meet here.

Compared to copper and stainless steel, aluminum is the most economic option considering thermal conductivity, rigidness, and cost. And many of these aluminum alloys base have been divided into classes, the commonly used on MCPCB are AL1060, AL3003, AL5052 and AL6061.

Do you know the differences between these substrates? This blog will give a brief introduction for you.

1060 alloys

AL1060 are commercially pure, unalloyed aluminum, it’s soft, ductile, workability and exceptional corrosion resistance, making it suitable for hard-forming applications. It can be welded with any method, but it cannot be heat-treated. Its cost is the lowest of the four types.

3003 alloys

AL3003 use silicon, copper, and magnesium as the main alloying elements, oftentimes with supplemental nickel and beryllium. They are heat treatable, have high strength, good resistance to cracking and wear, and have good machinability.

| Mechanical Properties | Metric | English |

| Ultimate Tensile Strength | 200 MPa | 29000 psi |

| Tensile Yield Strength | 186MPa | c |

| Shear Strength | 110 MPa | 16000 psi |

| Modulus of Elasticity | 68.9GPa | 10000 ksi |

| Shear Modulus | 25 GPa | 3630 ksi |

5052 alloys

AL5052 use magnesium as their primary alloying element and are not heat-treatable, but it’s the highest strength alloy of the more non-heat-treatable grades. Its resistance to fatigue is better than most grades of aluminum and have a great surface aesthetic when anodized.

In our company, if not special request or notes, the default material we use is AL5052 after considering all the performance and cost.

| Mechanical Properties | Metric | English |

| Ultimate Tensile Strength | 228 MPa | 33000 psipsi |

| Tensile Yield Strength | 193 MPa | 28000psi |

| Shear Strength | 138 MPa | 20000 psi |

| Modulus of Elasticity | 70.3GPa | 10200 ksi |

| GPaShear Modulus | 25.9 GPa | 25.9 760 ksi |

6061 alloys

| Mechanical Properties | Metric | English |

| Ultimate Tensile Strength | 310 MPa | 45000 psi |

| Tensile Yield Strength | 276 MPa | 40000 psi |

| Fatigue Strength | 207MPa | 30000 psi |

| Shear Strength | 96.5MPa | 14000 ksi |

| Modulus of Elasticity | 68.9 GPa | 10000 ksi |

| Shear Modulus | 26 GPa | 770 ksi |

AL6061 implement magnesium with silicon as their principal alloying elements. Their strength is improved with heat treatment. AL6061 is one of the most widely used aluminum alloys, it has high strength and superior corrosion resistance. Its weld-ability and formability make it suitable for many general-purpose applications.

Cost Comparison: AL1060 < AL3003 < AL5052 < AL6061

If you have other questions about MCPCB, welcome to contact Tammy (Email:sales@bestpcbs.com), she will prove you professional suggestions and solutions.