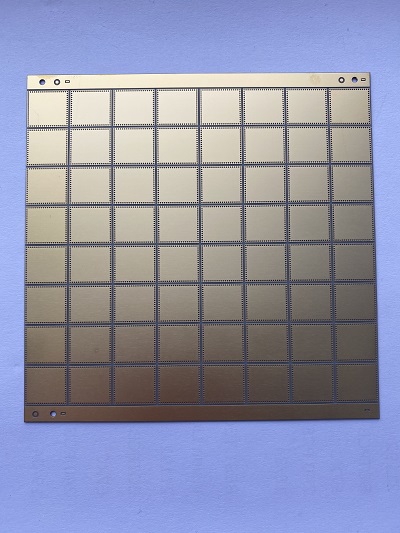

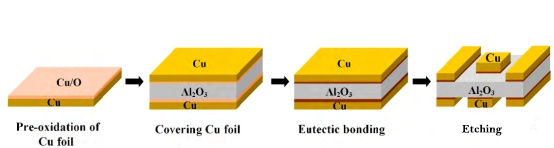

DBC means direct bonding copper, it is a ceramic surface metallization technology.

The copper is bonded on Alumina, Beryllium Oxide and Aluminum Nitride, Packaging applications for power electronic modules, semiconductor refrigeration and LED devices are widely used.

96% Al2O3 has good insulation, good chemical stability, high strength, and low price. It is the preferred material for DBC technology, but the thermal conductivity of aluminum oxide is low, and there is a certain thermal mismatch with the thermal expansion coefficient of Si.

BeO is a good ceramic material used in DBC technology. It has high low-temperature thermal conductivity. It can be used for medium and high power devices. In the application field and process, the toxicity caused by it should be properly protected.

AlN material is non-toxic, moderate dielectric constant, thermal conductivity is much higher than aluminum oxide, close to beryllium oxide, and thermal expansion coefficient close to SI. All kinds of chips and high-power devices can be directly attached to the AlN substrate. No transition layer of other materials is used. The prospects currently used in DBC technology are very promising.

There is no any layer between the metal and ceramic substrate, so the thermal diffusion ability is strong; the contact resistance is also low, which is conducive to the connection of high-power and high-frequency devices.

The linking temperature is lower than the melting point of copper, and the DBC substrate maintains a stable geometric shape during the connection process. In some cases, the copper foil can be made into the required shape before the linking, and then the DBC preparation process is performed, eliminating the need After connecting the etching process.

The copper conductor part has a very high current-carrying capacity, so it has the ability to reduce the size of the intercepting medium and increase the power capacity.

If you want to know more about DBC ceramic PCB, please feel free to contact sales8@bestpcbs.com