If you need a Metal Core PCB for your project, there are some different types can be selected, the selection of the MCPCB type depends upon the type of application and project you are performing. This blog will provide you information about the metal based PCB, which will also illustrate the construction, uses and distinguishing features of the MCPCB boards, hope it can help you to choose the most appropriate MCPCB for your subsequent projects.

Types of Metal Clad PCB

There are many different types of the MCPCB depending upon the type of base material, currently the most common metal used for MCPCB manufacturers are Aluminum, Copper and steel alloy. The selection of the base material depends upon the type and nature of the electronic project.

1) Aluminium core PCB

Aluminium is a better material that we can use for the core of a board. The reason is that it has high heat transfer capability. Moreover, it also shows the heat dissipation capacity to the maximum extent. Aluminium is also relavitively cheaper as compared to the copper material. Therefore, it represents the cheaper and better manufacturing of the printed circuit boards.

2) Copper metal core PCB

Copper is the best material for the core of MCPCB, since this material shows the best heat transfer capability. Moreover, this material is also fit for the excellent heat dissipation during the process. These features save the PCBs from the thermal issues.

The copper core PCB shows the best thermal conductivity as compared to other PCBs. The normal value of the thermal conductivity for these PCBs is 2.0W/mk. However, we can get this value of thermal conductivity up to 12W/mk in the case of insulating layer. Therefore, these types of the PCBs have the tremendous use in the high-power LED lights.

3) Stainless steel PCB

Another important material that has an excessive use in the metal core PCBs is the¬†Stainless steel PCB, which¬†also¬†can¬†provide better capability of connectivity and high performance, and it’s¬†more rigid than both aluminum and copper, but thermal conductivity is lower than them too.¬†

Stack up of Metal core PCB

The stack up and construction of the MCPCB depends on the number of layers in the PCB. The PCB with the single layer, two layers and multiple layers have the different methods of stack and construction.

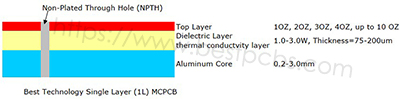

1) Single Layer Metal Core PCB

A single layer MCPCB consists of a metal base, Dielectric Layer, Copper Circuit Layer. The advantage is that it provides a better connection between components of the PCB, and it’s efficient at the heat dissipation in the high-power generator systems. These PCBs have the holes on the board for the mounting process of the electronic components. It can also have the screws around the chassis of the board for the arrangement of the components.

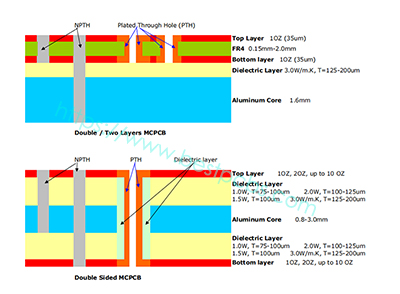

- Two (Double) Layers MCPCB / Double Sided More Core PCB

In some cases, there’s not enough space on the single layer PCB for the mounting of enough electronic components. So¬†we need to use the two layers¬†conducting material to resolve this issue.

Regarding the MCPCBs with two layers of copper conductor, there are two basic types, one is Two (Double) layers MCPCB, the other one is Double Sided More Core PCB, which depends on your demand of the mounting of the electronic components, the components can be soldered on both sides on Double Sided More Core PCB.

If you would like to know more details of the differences between Double Sided MCPCB and Double/Two Layers MCPCB, welcome to click following link.

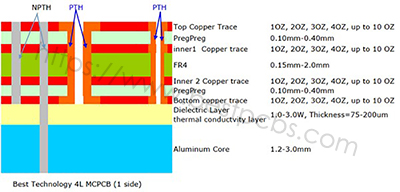

3) Multi Layers metal core PCB

The Multi¬†Layers¬†MCPCB¬†have the more complex and integrated circuit/construction, which can be populated more components on the boards, put signal and ground layer into seperated layers, to achieve better performance in electrical performance. It’s best for heat transferring from electrical components to the chassis of the board. The use of these boards is tremendous in the digital and analogue devices.

If you have any questions about MCPCB, welcome to contact Best Technology.