Via Tented, Via Filled (filled with solder mask) & Via Plugged (Via In Pad – Conductive material or Non-Conductive material)

One of the most confused idea during our PCB design is the difference between Via Tenting, Via Filling and Via Plugging. Designers often get mixed up between them and fail to take full advantage of the process.

Today, let us discuss them, so that you can be confident in specifying your design requirements clearly when submitting PCB files to Best Technology before final manufacturing.

Via Tented

What is via?

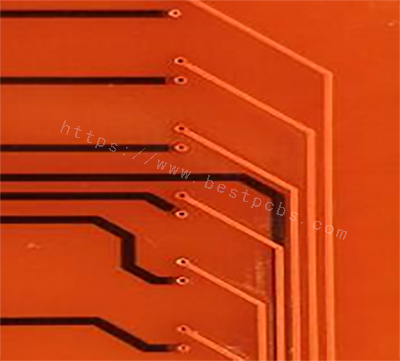

A plated through hole (PTH) in a Printed Circuit Board that is used to provide electrical connection between a trace on one layer of the Printed Circuit Board to a trace on another layer. Since it is not used to mount component leads, it is generally a small hole and pad diameter.

A. Three methods and definitions of via processing

There are three methods for via processing: via hole opening & via hole cover oil & via hole plug oil

1. Through hole opening window: it is the tin on the solder ring of the via (the tin is exposed like a plug-in pad). The window is usually used to debug the measurement signal. The disadvantage is that it is easy to cause a short circuit.

2. Through hole cover oil: it is the welding ring of the through hole (via) covered with solder mask ink

3. Through hole plugging oil: refers to plugging the hole with ink.

Secondly, the inspection standards for a processing method

1. Through-hole opening window is like a plug-in pad, and the window is sprayed with tin. Inspection standard: tin can be tinned, and tin can be easily tinned.

2. The inspection standard of the via hole cover oil: it is not easy to tin in the patch.

3. Inspection criteria for via plug oil: First, it must be opaque, and it must be covered and blocked by ink.

Finally, we are talk for comparison and distinction between via hole cover oil and via hole plug oil:

1. Via plug oil This process is an important supplement to via plug oil, so generally high-quality boards will require via plug oil. And often many engineers who are just entering the industry are stupid and unclear. So how do you distinguish between the two?

2. The requirement of via hole cover oil is that the ring of the via hole must be covered with ink. The emphasis is to ensure the thickness and coverage of the ink on the edge of the hole. The key control is that the ring does not accept false copper exposure and orifice oil. Thin

3. Through hole plugging oil is the production of plug holes with ink inside the holes of the through holes. The emphasis is on the quality and density of the plug holes. After the holes are plugged, no light can be transmitted.

4. The method of plugging the via hole is to first fill the via hole with ink to block the via hole, so that the ink on the solder mask will not flow into the via hole, so as to achieve the situation that the via hole does not appear yellow. (If you have strict requirements and place an order for via hole cover oil, the cover oil is usually not full or yellowish, you can change it to via hole plug oil later). In addition, the smaller the vias are, the easier it is to plug them. The vias of the fortress oil are not easy to be too large (the circuit board proofing plugging oil is directly plugged with ink, and the printing tape is plugged. It is recommended that the vias that need to be plugged are designed to be <0.5mm. This is also free; no additional money is required).

If you have more question Via Tented, Via Filled& Via Plugged, warmly welcomed to contact Best Tech for more FR4 design service.