Last time we have talked about the structure difference between the aluminum PCB and ceramic PCB. So, based on the different structures, whose thermal conductivity is better?

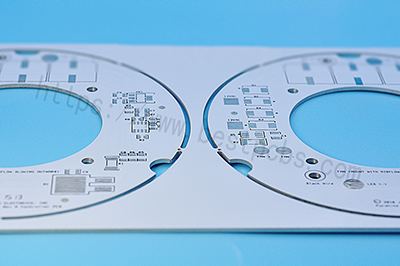

We have known that a single layer aluminum PCB is made up of copper layer, dielectric layer and aluminum layer. Meanwhile, the dielectric layer is the decisive factor affecting the thermal conductivity.

Generally, its thermal conductivity ranges from 0.8 to 3.0 W/m-K, but can up to 8.0 W/m-K. So, in terms of heat dissipation, the aluminum substrate does much better than FR-4 substrate. And it is a good choice for LED lighting products with high power.

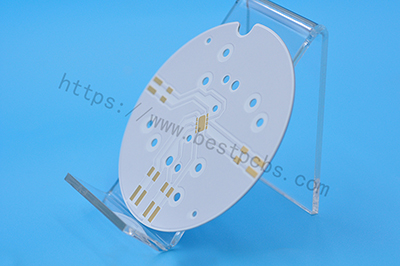

However, the heat-conducting property of ceramic PCB is superior to that of the aluminum PCB.

Since ceramic itself is an insulating material with a great heat-conducting property, it does not need a dielectric layer. Therefore, the heat can be dissipated directly through the ceramic.

Because of its excellent performance in heat dissipation, it is particularly suitable for the lighting product with ultra high power and those products which have a high demand of heat dissipation.

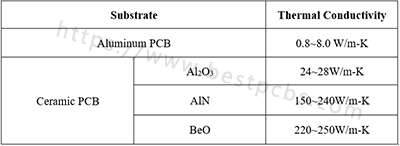

To summarize, clearly, we can know from the table below that ceramic PCB does better than aluminum PCB in terms of thermal conductivity and heat dissipation. And this is mainly because of the dielectric layer, which is related to the functions of bonding, insulation and heat conduction.

The better the heat conduction performance of the insulating layer, the more conducive it is to the diffusion of heat generated during the operation to the device, hence it will be more conducive to lower the operating temperature of the device. That is to say, aluminum PCB will be subject to the dielectric layer, while ceramic PCB will not be restricted.

And, this is the end of the comparison of the thermal conductivity between aluminum PCB and ceramic PCB. If you still have any questions about them, please feel free to contact us.