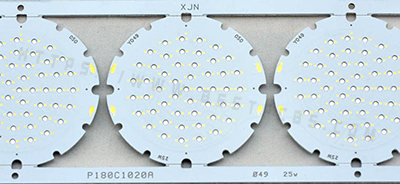

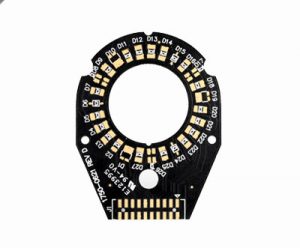

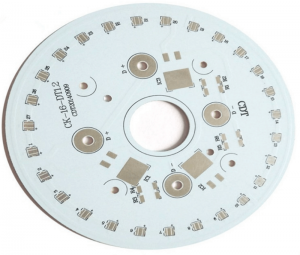

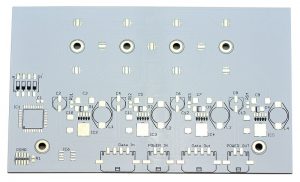

MCPCB refers to metal core printed circuit board. It has a good performance in heat dissipation, so it is often used in LED products.

The advantages of MCPCB

Prevent overheating:

LEDs tend to get overheated very quickly. If a metal core printed circuit board is used, it solves overheating by transferring the energy from one side to another.

Improve the materialÔÇÖs reliability:

The MCPCB plays a key role in the elements that heats up overly at times. It helps to divert the heat from one side to another where the heat has vanished, which improves the productÔÇÖs life, making it much more durable.

Adapt to a high temperature:

Unlike the FR4 technology, the metal core printed circuit board can adapt to products with a high temperature, hence it proves to be very useful for LED products.

Why is the MCPCB widely used in the LED products?

Since it is well-known that the LED products will emit a lot of heat. Based on the advantages, the metal core PCB can transfer heat quickly and prevent overheating. And Aluminum PCB is mostly used in metal core PCBs, for they can operate longer than other metals and longer shelf life.

Moreover, metal core PCB has a high conductive ability, hence there remains ample space for maximum LEDs, which allows producing sufficient light and achieving high performance.

Therefore, based on the advantages of the MCPCB, it is the prior option of the material for the LED products.

So, this is the end of the article. In case if you have any questions, you are welcome to contact us via email at  sales@bestpcbs.com. We are fully equipped to handle your PCB or MCPCB manufacturing requirements.