With the development of technology, we need the MCPCB to be multi-layer. 1 layer MCPCB is not enough for making some high-quality precision equipment and products.

So now, 2 layers MCPCB becoming more and more popular.

Normally, we make 1OZ, 2OZ and 3OZ copper thickness for each layer for aluminum or copper core/base PCB. The thickness of copper for top and bottom layer are the same.

But recently, more and more customers want the MCPCB to be made with different copper thicknesses on top and bottom layer.

For example, they want 1OZ copper on top layer and 3OZ on bottom layer.

But we donāt suggest to do that, why? Let me do some explanations.

- Different copper thicknesses on top and bottom layer will increase the difficulty for production. Because we put the MCPCB into etching liquid to do the etching, we need to use film to protect one side from etching liquid, but if it canāt be protected well completely, it will be etching too, then it is rejected.

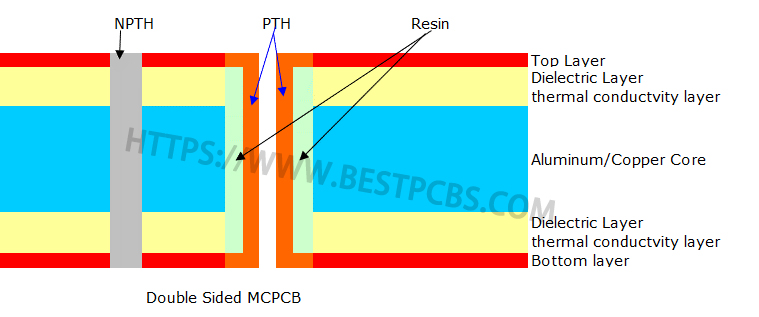

- Different copper thicknesses on different sided will cause the PCB twist finally if the stack up is double sided (See below double sided stack up)

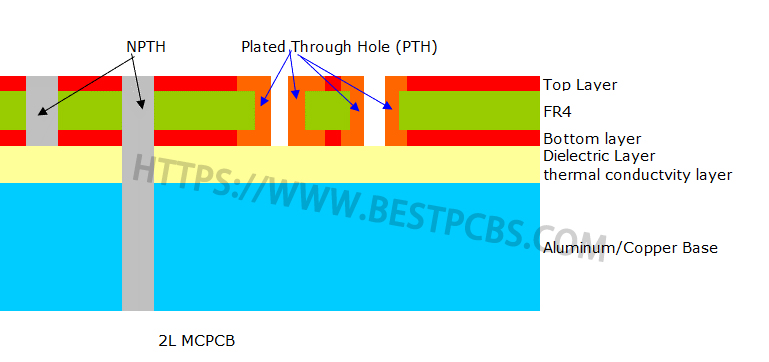

But if the stack up is 2L (See below 2L stack up), the FR4 PCB is twisted then will affect the lamination for FR4 PCB and aluminum/copper base.

- Due to increase the difficulty of production, so the price will be increased too.

- Lead time will be longer than normal since the production process is much more completed.

- The reliability is not good.

Finally, it is better to do the same copper thickness for each layer for multi-layer MCPCB.

For knowing more knowledge about MCPCB, please email to sales8@bestpcbs.com