With more and more extensive usage of Printed Circuit Boards, the IC become more and more integrated and IC pins on PCB are also more denser (such as 0603, 0402 spec ICs), which brings a big difficulty to SMT process. In addition, the shelf life of HASL board is very short, and Gold-plated board can solve such problems perfectly, thatâs why it is common and popular to use gold board in high precision and ultra-small assembly process. Nowadays, there are two kinds of gold coating method in PCB industry â Immersion gold & Gold plating. To make you a sense of them, today we will simply introduce their definition and the differences between two of them.

Part 1: What is Immersion Gold (ENIG)

Immersion Gold also named as ENIG (Electroless Nickel/Immersion Gold) is generating a layer of coating by chemical REDOX reaction, is a kind of chemical nickel gold deposit surface finish during PCB manufacturing process. We can get a thicker layer of gold, but as its weak adhesion through immersion, it is also known as Soft Gold.

Part 2: What is Gold Plating

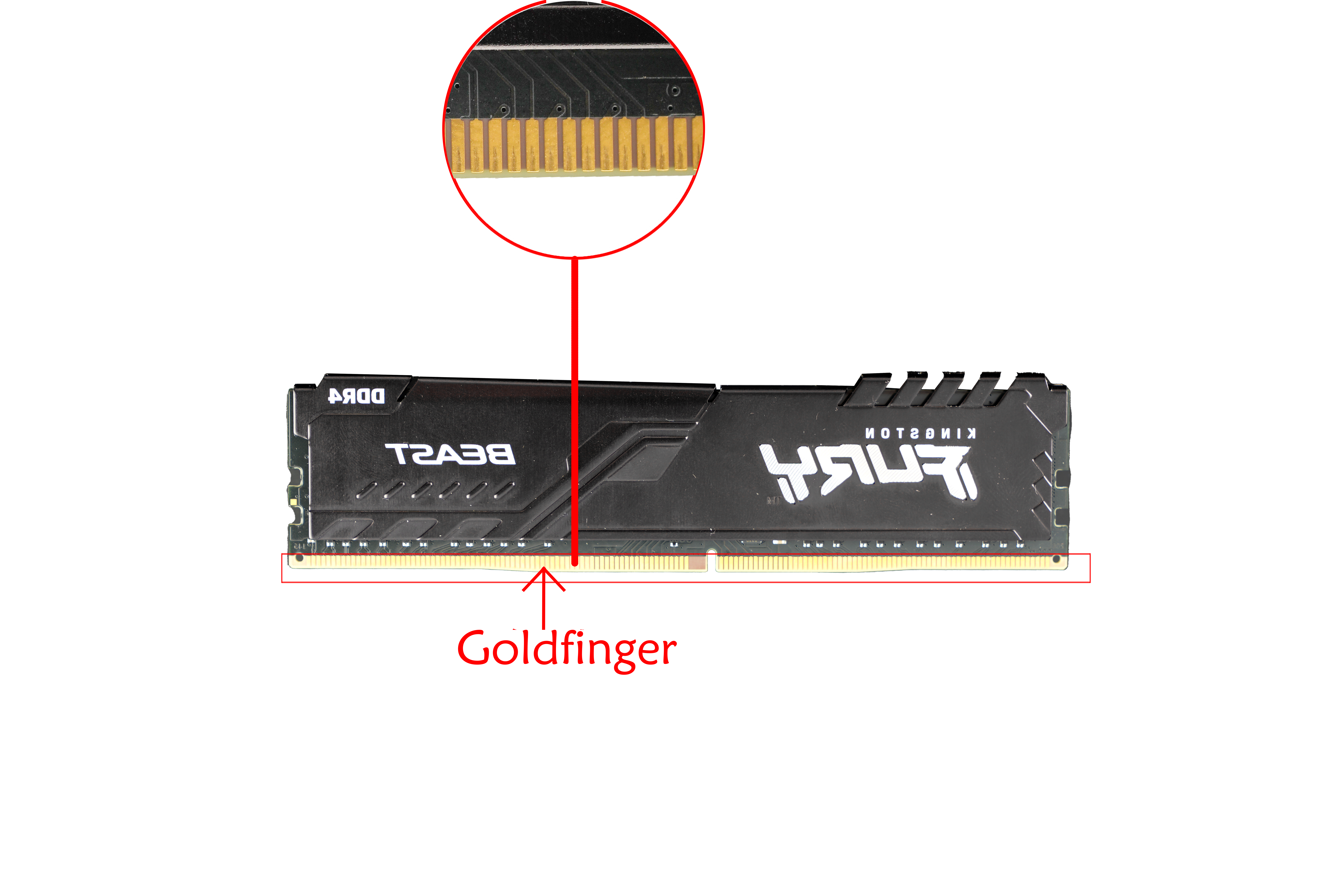

Gold plating is an another surface treatment of depositing a thin layer of gold on PCB surface by plating, the working principle is to dissolve nickel and gold (commonly known as âgold saltâ) in the chemical potion, then immerse the circuit board in the electroplating cylinder and through the current on the copper foil surface of the PCB to generate a layer of gold plating. The gold particles attached to the PCB, as strong adhesion also known as âhard goldâ. Gold plating is widely use in electronic products as its characteristics of hardness, excellent abrasion resistance and not easy to be oxidized. For example, the gold finger of flash driver in our computer is hard gold.

Part 3: The differences between Immersion Gold and Gold Plating

- In generally, the gold thickness of immersion is thicker than plating, and immersion gold is golden yellow while gold plating is yellowish white, so just from appearance, most customers prefer like immersion gold.

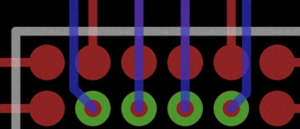

- Due to the crystal structures between them are different, immersion gold is easier to operate in SMT process, and wonât cause the poor soldering issue.

- Immersion gold is softer than plating way, so if boards required gold fingers, it is always use plate-gold as its good wear resistance properties.

- There is only nickel gold on the solder pad, so under the conductor skin effect, the signal transmission wonât be affected in copper layer.

- Compared with gold plating, immersion gold has more denser crystal structure and is not easy to oxidation.

- With the denser line width and space requirements, plating method is easily to cause short circuits, but since immersion gold board only has gold on solder pads, which wonât exist such issue.

- The adhesive between solder mask and copper layer on circuit is stronger as there is only nickel gold on immersion board, so it is easier for engineers to make compensation when adjust line space.

- Black-Pad wonât be happened to immersion board after assembly because it has good flatness than plating method.

- Immersion gold is more economy than plating.

Best Technology is a professional PCB manufacturer with over 16 years experiences, and we have rich and mature technical to fabricate immersion gold and gold-plated boards. Warm welcome to contact us at sales@bestpcbs.com if you have any questions or RFQs about printed circuits, we are always online.

Tags: surface treatment