When finish the PCB design, we should choose a suitable surface finish to protect traces from corrosion. Nowadays, the most popular surface treatments for PCB manufacturer to use are HASL/LF HASL, OSP and ENIG.

Different surface treatment has its unique functionality and the cost also is different. This article we will show you the pros and cons of the three surface finishing which use while the PCB manufacturing process.

HASL Surface Finish

HASL (Hot Air Solder Level) can be known as tin-lead HASL and lead-free HASL, it was the mainstream surface treatment technology in the 1980s, but with the increased of “small and high density” demands in PCB, there are less and less circuit boards use the HASL technology because it will cause the defective products due to the solder point are easy to leave on the board surface during SMT process. In view of this situation, some PCB board manufacturers or designers prefer use OSP or immersion gold to ensure the good quality products as well as smooth production process.

- Tin-lead HASL

Advantages:

1) Economical and widely available.

2) Excellent solderability.

3)Better mechanical strength & lustrousness than lead-free HSAL.

Disadvantages: it is harmful to environment and violates RoHS compliance.

- Lead-free HASL

Advantages: low cost, good solder performance and environmental.

Disadvantages: mechanical strength & lustrousness are not good than lead HASL.

In additional, due to the poor surface flatness of HASL circuit boards, neither leaded nor lead-free HASL is not suitable for soldering fine-pitch components or plated through-holes, because it will cause the short circuits and poor welding during the assembly process.

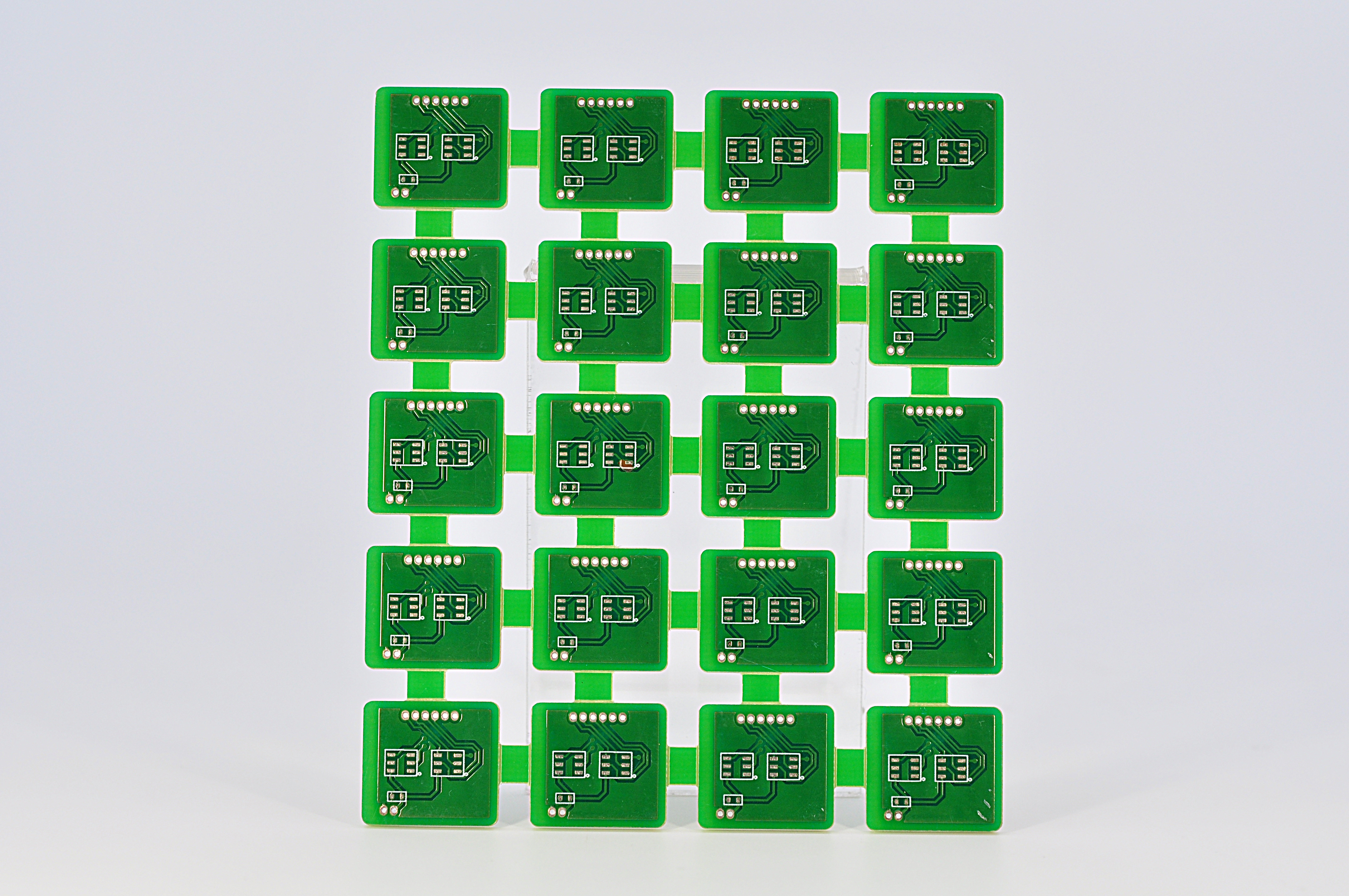

OSP

OSP (Organic Solderability Preservatives) also named as pre flux, the working principle is to generate a layer of organic film chemically on the copper surface to protect the surface from oxidation or vulcanization in the room environment. Meanwhile, OSP also can increase the oxidation resistance, heat shock resistance and moisture resistance of a PCB.

OSP is equivalent to an anti-oxidation treatment, the protective thin film can be easily removed by the flux quickly under the high soldering temperature, then it makes the exposed copper surface immediately combined with the molten solder in a very short time to become a solid solder spot.

At present, the usage of OSP surface finishing process has increased significantly because it is appropriated for both low and high-end products. If your application has no surface connection functional requirements or storage life limitations, the OSP process is the most desirable surface treatment process.

Advantage:

1)With all the advantages of bare copper soldering, expired (more than 3 months) boards can also be resurfaced, but one time is better.

2)Good for fine-pitch, BGA and smaller components.

3)Low cost and easy to rework.

4)Simple process and easy to ensure quality.

Disadvantage:

1)OSP is easily affected by acid and humidity, so must be packed with vacuum.

2)Need to do surface treatment again if storage time more than 3 months.

3)It should be used within 24 hours after unpacking.

4)OSP is an insulating layer, so the test point must be printed with solder paste to remove the original OSP layer for electrical testing.

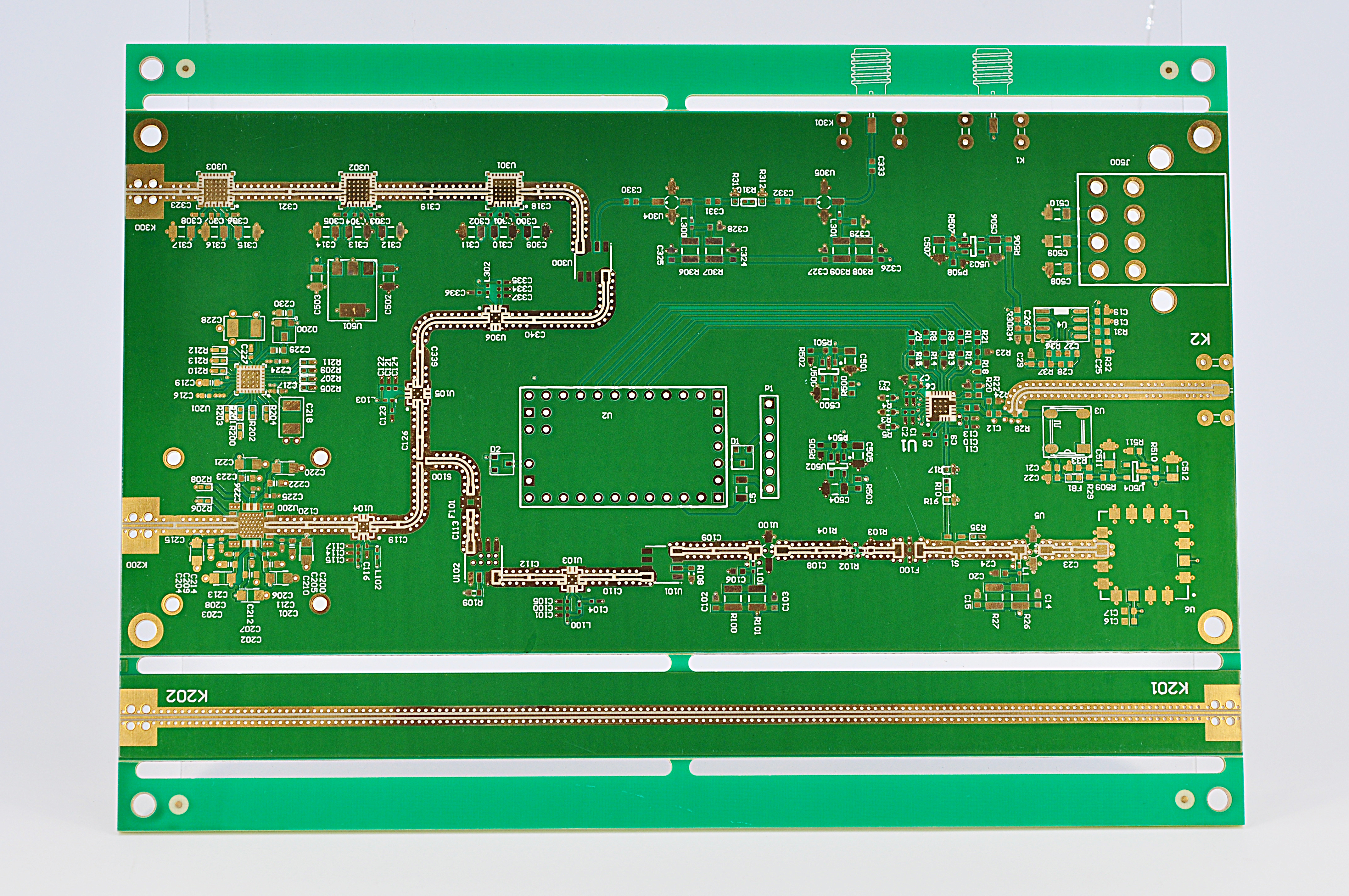

ENIG

ENIG (Electroless Nickel/Immersion Gold) is one of a chemical nickel gold deposition method, the working principle is to generate a layer of coating by chemical REDOX reaction to get a thicker gold layer. Currently, ENIG is mainly used in the surface of the circuit board with connection functional requirements and long storage life.

Advantage:

1)Can be stored long time as well as no oxidation.

2)Good flatness surface and suitable for small solder point components.

3)Good solderability.

4)Can be used as the base material for COB wire bonding.

Disadvantage:

1)High cost than other two surface treatments.

2)Easy to exist black-pad issue during production process.

As we can know from above information, each PCB surface treatment has its own merit and demerit, you can choose the one according to the effect you want to reach, as well as your cost.

If you don’t know which is best for you, you can send inquiry to us, our professional engineering team and PCB sales will choose the suitable one for you. Welcome to contact us if you have any other questions.

Tags: surface finish, surface treatment