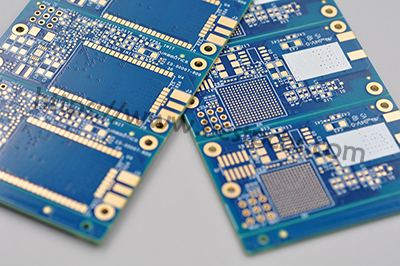

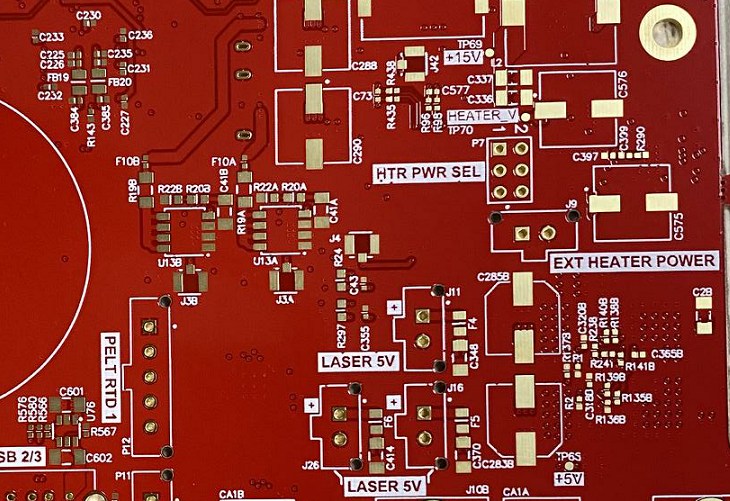

If you’ve ever learned a printed circuit board, you may see some silkscreen legends printed on the PCB. Silkscreen legend plays an important role in PCB production process. Therefore, the quality of silkscreen also is significant.

Last time we share some acknowledges about silkscreen guideline, today we will introduce how to make PCB silkscreen on the Automatic Silkscreen Printer step by step for you.

Manufacturing processes of printing silkscreen

- Screen fix

Step 1, we need to fix the screen on the base or workbench with a fixture, and leave 3-5mm distance away from the positioning plate when put the screen.

- Align and position

Step 2, we need to place the circuit board on the positioning plate with right-angle positioning method or stud registration method (generally use 2 positioning pieces), make it fixed and aligned, then put down the stencil frame and adjust the positioning button, so that the PCB outline is roughly overlapping with screen. Next step, perform initial align boards according to the positioning holes or outline line, then gradually adjust to the optimal position based on pads.

- Silkscreen ink selection and fine-tune

Step 3, we need to select the silkscreen ink according to the customer requirements, put down the screen frame and poured ink into the screen frame, and then select the length of the appropriate scraper for trial printing sample, and fine-tune the positioning until accurate.

- Trial printing

Step 4, we will need to do trial printing the prototypes with transparent character alignment film and check to see if there is a legend deviation, if no, then we can proceed with mass production, but if not, then the positioning should be fine-tuned again, rip off the defective film and affixed with the new one then printing again, repeat trail until qualified.

- Screen printing (manually)

Step 5, let’s place the circuit board (which have finished surface treatment process) on a fixed position, put down the screen frame, and then hold the scraper with both hands, at an Angle of 50°- 60 ° with even force on the scraping screen surface from front to back or from back to front. The printing material is subjected to the pressure of the scraper through the printing mesh hole and printed on the circuit board. After the scraper passes through, the screen recovers by its own tension. After the scraper is finished, the screen frame is lifted, and the sealing screen printing material is scraped back.

- Screen printing (auto printer)

Step 6, the Angle of the scraper is an external “eight” font, usually between 20-30 degrees, you can choose the printing times according to the actual needs.

In the past, most of the factories make the screen printing manually, it is time consuming and limited to relatively short lengths of 60 yards. So, in our manufacturing line, we have imported the automatic flat-bed screen printing.

Here I would like to share some features of the PCB silkscreen printer with you:

Features of Auto-Printer

- High speed: the automatic screen printer has its own unique frequency conversion speed regulation device, the printing speed can be adjusted from 20 to 70 times per minute auto screen printing machine.

- Cost-effective: the auto printer has its own electronic counter, which can automatically shut down according to the pre-designed total number, saving a lot of manpower and ink material.

- Good quality: the automatic screen printer is very accurate in point and color, because it is equipped with a multi-color printing electric eye device, which can improve the quality of printing.

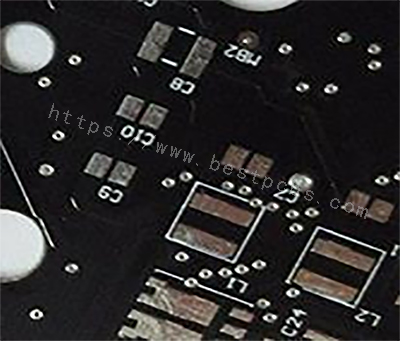

- Good adhesive: the adhesion of the screen machine is very good, and the ink layer is relatively thick, so the text legend is not easy to fade.

- Multi-aspect: the fully automatic screen printer can not only be used alone, but also can be connected to a UV dryer, or a slitting machine, a reminder, and other auxiliary machines.

With the help of Automatic silkscreen printer, we are able to provide “faster” and more “efficient” service to our customers, warmly welcome to contact us, we are ONLINE always!