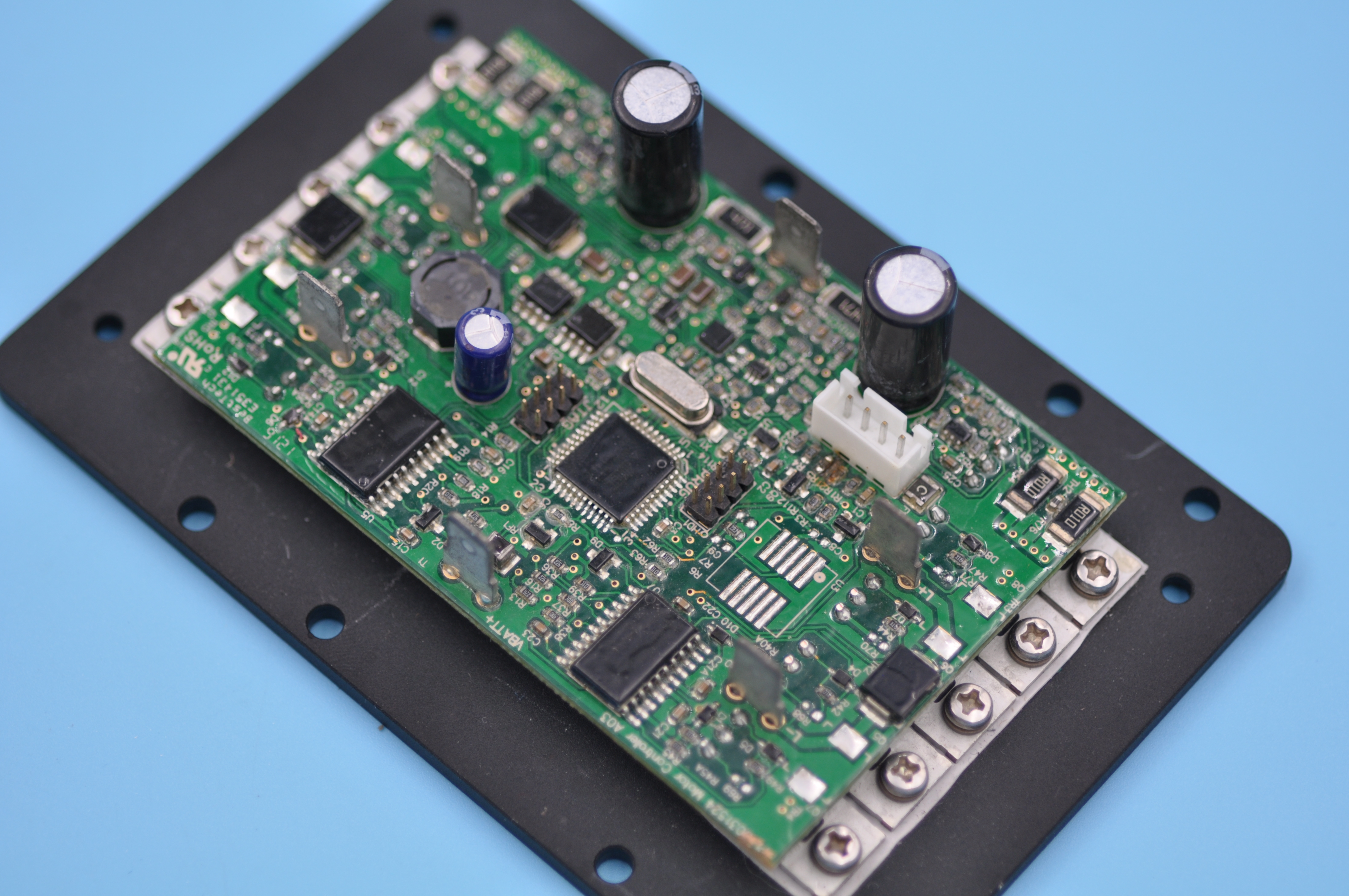

With the great demands about high-tech electronic equipment, although the single sided PCB or double-sided printed circuit boards have their advantages, multi-layer designs are more beneficial for some applications, that’s why the more and more popular and wide usage of multi-layer PCBs.

Currently in the market and electronic industry, almost of the multi-layer PCB have an even number of layers such as 8, 10 or 12 layers, why designers didn’t consider an odd-number layers? Today let’s explore the reasons together.

- Higher cost spent

Normally the standard layers of a multi-layer PCB in the industry are even-numbers, and as the manufacturing technology becomes more and more mature, the cost of fabricating a multi-layer PCB is relative competitive.

But if you want to produce odd-numbers PCB, may the odd-number layers save the cost of material for one layer but the processing cost increase significantly to an even-numbers. Because the core structure requirement for odd layered PCB increases the production cost greatly. However, an even layered PCB can save these costs and reduce the overall manufacturing cost, so why not consider the even number layers?

- Long lead time

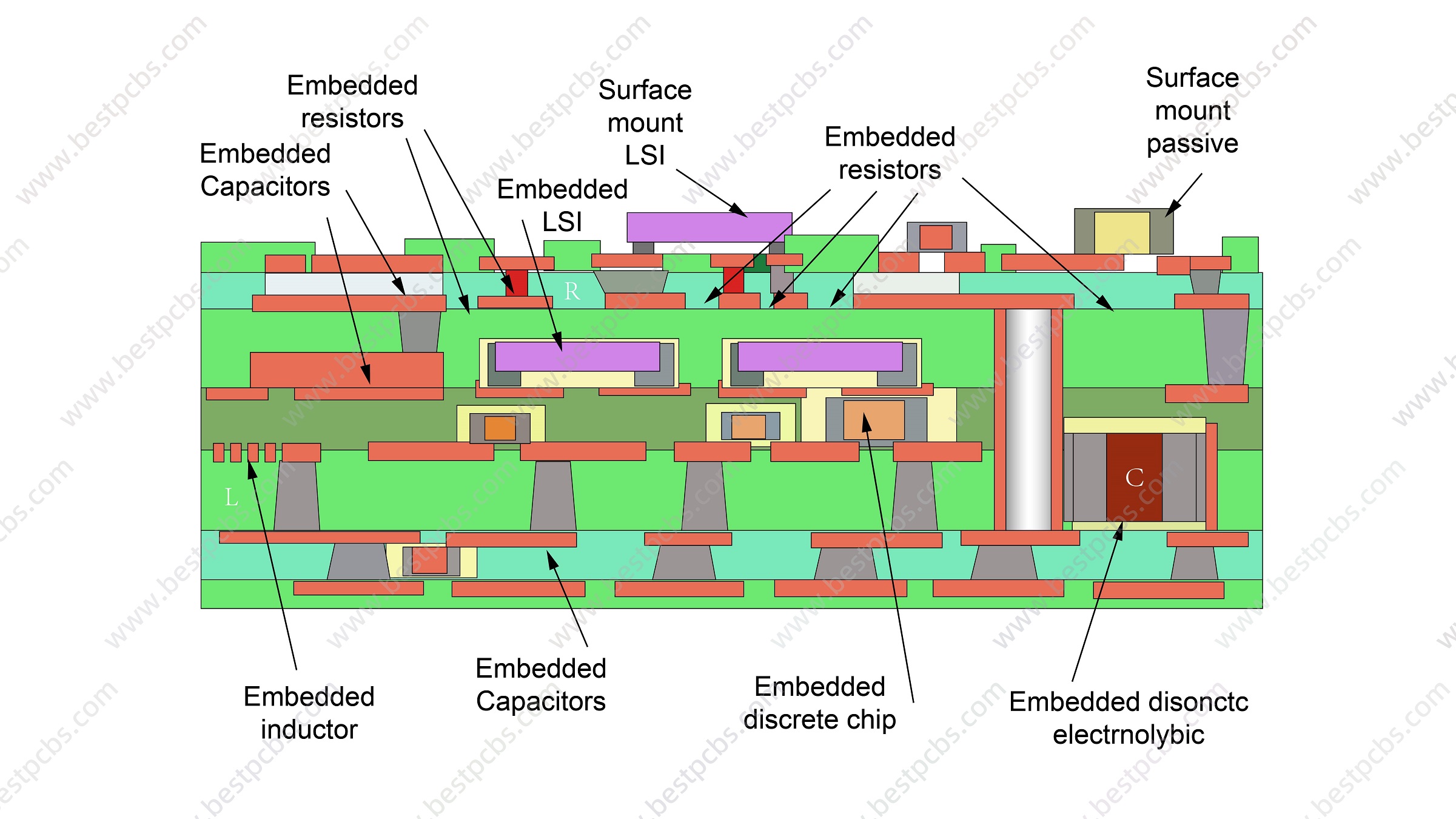

Long delivery time is unescapable because of the immature fabricating technology. In particular with the odd-layer, the stack up will be unbalance. For example, if it’s an odd layered circuitry, due to the standard symmetrical requirement, the layers will be separated to 2 layers in a one side and another side is 3 layers, so one of the copper layers will be etched away and the odd layered PCB may create uneven weight during the copper plating stage and result in irregular plating issues. This non-standard, odd-layered stack requires an extra core process for layer bonding and adds to the manufacturing time and cost. So, it’s always recommended to use an even number of layers in the PCB stack-up.

- Potential quality issue

Quality is very important and crucial for end-application, and the best reason of why not design an odd-number multi-layer PCB is the odd-number layers PCB is very easy to get twist due to the unbalance copper layers. When the PCB is cooled after the multi-layer circuit bonding process, the different lamination tension between the core structure and the foil structure can cause the PCB to bend when cooled. As the board thickness increases, the risk of bending becomes greater for composite PCBs with two different structures. The key to eliminate circuit board bending is to use balanced layering. Although PCBs with a certain degree of bending meet the specification requirements, subsequent processing efficiency will be reduced, resulting in increased costs. Because assembly requires special equipment and technology, the accuracy of component placement is reduced, so the quality will be damaged.

In addition, the twist of an even-number layers PCB can be controlled below 0.7% (IPC 600 standard), but odd layers unable to reach to this quality standard. What’s more, when the warpage of a circuit board greater than 0.7% will seriously affect the operation of Surface Mounted Technology (SMT) process and the reliability of the whole product. Therefore, the designers do not design odd layer generally, even if the odd layer enables to achieve the function, will be designed into false even layer, that is, 5 layers designed into 6 layers, 7 layers designed into 8 layers of board.

Anyway, more layers it is, more complex & difficult the manufacturing will be, and more expensive the cost will be, and the lead time of multi-layer PCB also is different from normal one. So you must choose a right supplier who can provide One-stop service include designing, evaluating, manufacturing or even repairing. Best Technology is an expert in the production of multi-layer PCBs for many companies around the world for over 16 years. Contact us right now and send us inquiries, we are so confident that we can be one of your most reliable suppliers in China.