In the pursuit of brighter smiles, teeth whitening devices have become indispensable tools, utilizing various techniques to enhance dental aesthetics. Among these, light-based approaches, such as phototherapy and laser treatments, play a significant role. Interestingly, these advanced methods, including ultrasonic vibration, often rely on a crucial technological component – the Metal Core Printed Circuit Boards (MCPCB). In this blog, we will explore the concept of teeth whitening devices, the technology employed, and delve into why metal core PCB, particularly preferred for LED products, are integral in crafting efficient and reliable teeth whitening instruments.

What is the Purpose of Teeth Whitening Equipment?

Teeth whitening devices are designed to improve the color of teeth, aiming for a whiter and brighter appearance. These devices apply various techniques, each contributing to the overall effectiveness of the whitening process. Notably, light-based methods have gained prominence, with two prominent technologies standing out: light phototherapy and laser treatments.

Light Phototherapy: This approach involves using specific wavelengths of light to activate whitening agents on the tooth surface. Patients wear protective eyewear while the device emits light, expediting the whitening process.

Laser Treatments: Similar to phototherapy, lasers target whitening agents, enhancing their efficacy. Typically conducted in professional dental settings, laser treatments offer precise and accelerated teeth whitening.

Ultrasonic Vibration: Some devices employ ultrasonic vibration, utilizing the principle of mechanical oscillation to enhance the penetration and effectiveness of whitening agents.

Why choose MCPCB for Teeth Whitening Devices?

Behind the scenes of these advanced teeth whitening technologies lies a critical component – the metal substrate. Often, LED products utilized in teeth whitening devices prioritize metal substrate for their construction. But what exactly is a metal core PCB, and why is it the preferred choice?

Understanding Metal Substrates: The Foundation of Reliability

MCPCB (Metal Core Printed Circuit Board) is a specialized type of printed circuit board characterized by the presence of a layer of metal with excellent thermal conductivity on the substrate. Typically, MCPCBs are composed of a metal core, insulating layer, and copper foil, with the thermal conductivity of the metal core being a significant distinction from conventional FR4 circuit boards.

Key Features of Metal core PCB: Unveiling secret

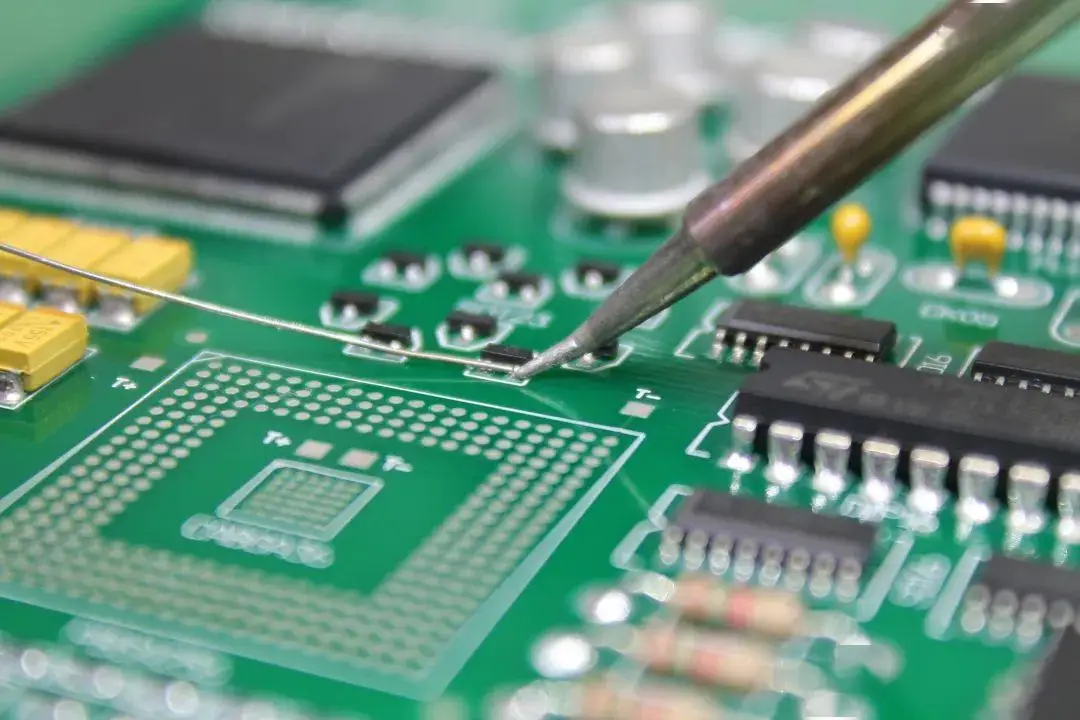

Superior Thermal Conductivity: Teeth whitening devices often utilize technologies such as light or laser, generating heat during operation. the metal core of MCPCB exhibits exceptional thermal conductivity, effectively dissipating heat to prevent overheating. This property ensures efficient heat dissipation, a critical factor in devices requiring prolonged operation, such as teeth whitening instruments.

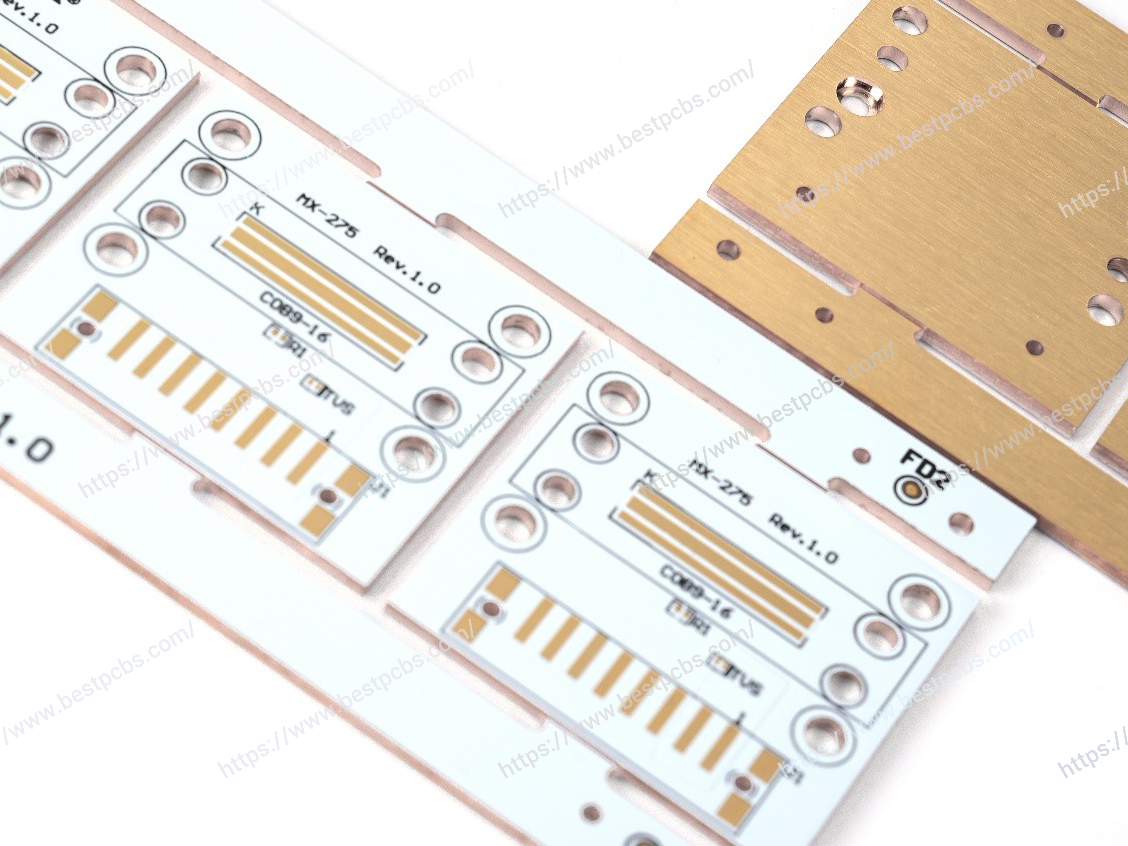

Regarding the metal base of MCPCB, aluminum base or copper base are commonly used for MCPCB, it’s also help to make the good heat dissipation than FR4PCB, like aluminum base has 205W/m.k and copper base has 398W/m.k, as you can see the thermal conductivity of copper base is better than aluminum base, so if your products need a more higher heat dissipation, welcome to consider copper core PCB, but please noted that copper is expensive than aluminum, which material depends on your requirement.

As thermal conductivity, it’s more important in MCPCB, since the higher the thermal conductivity, the higher the ability of heat dissipation, for now, the highest thermal conductivity is 8W/m.k in Best Technology, but for normally, 1W/m.k, 2W/m.k and 3W/m.k is enough for LED products.

Enhanced Heat Dissipation: MCPCB excels in dissipating heat, preventing overheating during prolonged use. This characteristic is crucial in teeth whitening devices, where maintaining a balanced thermal environment is essential for both device performance and user comfort.

Mechanical Strength: Metal substrates exhibit high mechanical strength, withstanding the rigors of assembly and use. This durability ensures the stability and reliability of the devices over time.

Structural Robustness: Teeth whitening devices may experience mechanical stress during operation, including vibrations or movements. The metal core of MCPCB provides additional structural support, enabling the device to withstand mechanical pressures and enhance overall durability.

Ideal for LED Products: MCPCBs are often the preferred choice for LED products due to their excellent thermal management and structural stability. LED-based teeth whitening devices benefit significantly from MCPCBs, ensuring the longevity and reliability of the LED components.

Why Metal Substrates for Teeth Whitening Devices?

The choice of metal substrates in teeth whitening devices, especially those employing LED technology, is strategic. The need for a material that offers robust electrical conductivity, efficient heat dissipation, and structural integrity aligns perfectly with the characteristics of metal substrates. In LED products, where precision and reliability are paramount, metal substrates emerge as the preferred foundation.

In conclusion, the convergence of advanced technologies for teeth whitening and the reliability of metal substrates highlights the intricate dance between innovation and foundational support. As we continue to seek brighter smiles through cutting-edge dental aesthetics, the role of metal substrates remains fundamental, quietly empowering the devices that illuminate our smiles and boost our confidence.

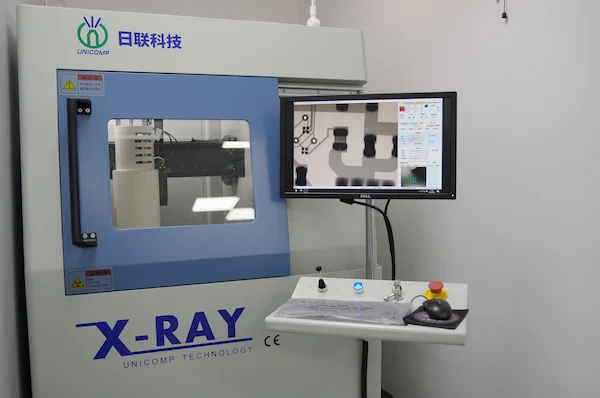

Best Technology has involved in MCPCB industry from 2006, over 17years, we can help to design, manufacturing and assembly, providing one-step service for our customers, welcome to share your drawing or idea to us, we will back you the best solution!