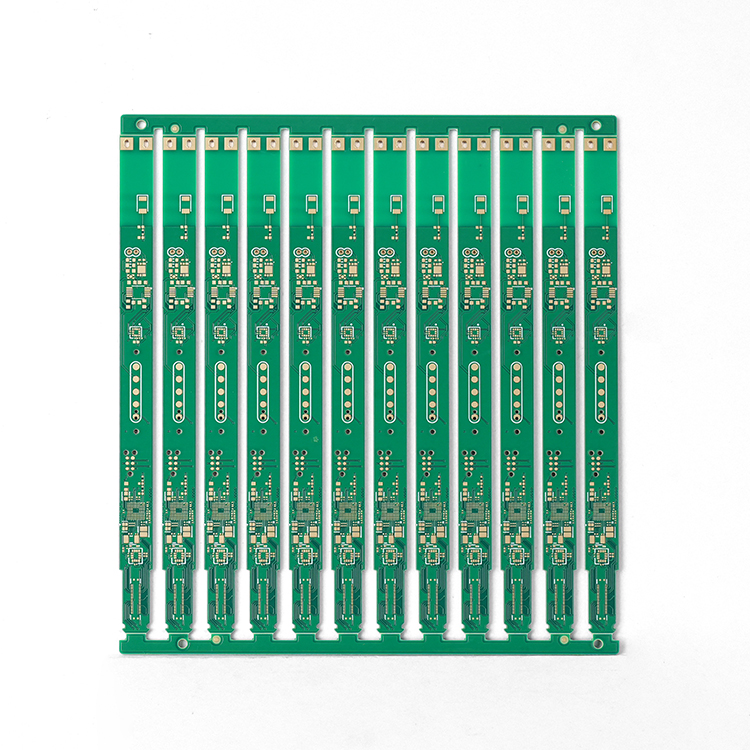

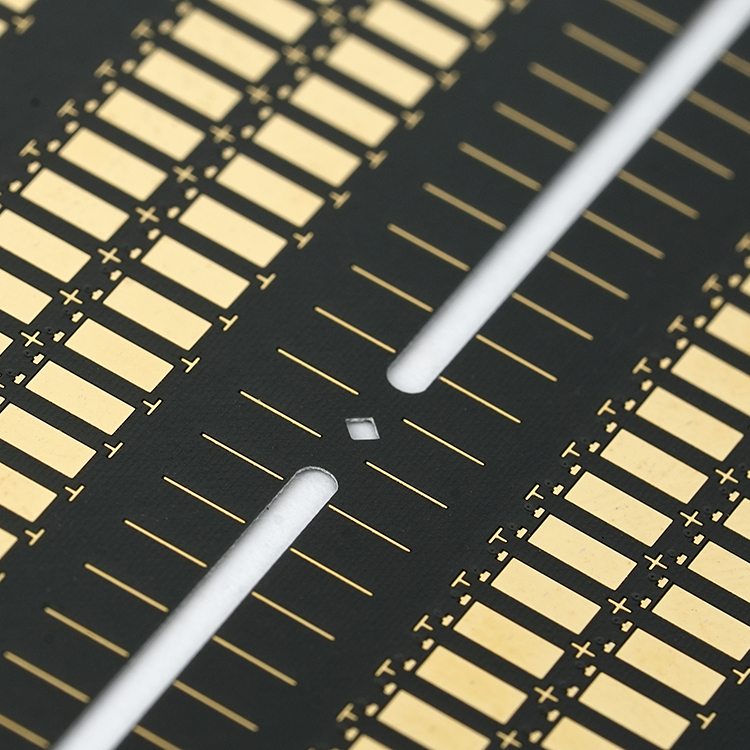

This category of ultrathin printed circuit boards is characterized by a thickness lesser than standard FR4 PCBs and generally finer than 0.60mm. But sometimes, due to space or margin limitation, or even design purposes, people need much thinner thickness such as 0.25 mm, 0.20 mm, or even 0.15 mm, so that it can be used by the PCB, such as SIM Card, Sensor Card, and so on. Due to thin thickness, extra thin PCB or very thin PCB name has been coined.

What are the Applications of Ultra-thin PCB?

Ultra-thin printed circuit boards (PCBs) are quite specialized items, helpful to find applications in several industries due to their flexibility, reduced weight, and space requirements. Given below are a few areas wherein ultra-thin PCBs would add more value:

1. Wearable Technology

With wearables dictating minimalist designs, thin PCBs offer just the right solution. Their thinness ensures a perfect fit in wristbands, smart clothing, and medical patches for an improved user experience in comfort and battery life.

2. Mobile Devices

The same can be said about PCBs as the relentless race continues for ever-thinner smartphones and tablets. Being thinner will continue enabling engineers to shove more processing power into a tight space.

3. Aerospace and Defense

In the world of satellites and drones, weight is critical. Besides being rugged, thin PCBs are lightweight; they allow intensive avionics systems to function faultlessly without adding their own unwarranted heft.

4. Flexible and Foldable

Innovators can easily create new product designs using flexible PCBs that bend and flex. From foldable phones to curved displays, the product will survive repeated cycles of bending and yet have low impedance.

5. Medical Devices

Miniature implantable medical devices require PCBs that are both small and biocompatible. Thin PCBs fulfill this need because they assist medical devices in being used in minimally invasive procedures and, besides, by way of example, give patient comfort since such patients can wear these devices for long periods.

Which Kind of Surface Finishing Can be Used on Ultra-thin PCB?

Common surface treatments used in extra thin PCB often include OSP (Organic Solderability Preservative), ENIG (Electroless Nickel Immersion Gold), or hard gold plating for the very best durability, conductivity, and environmental resistance. Now, thin PCB technology becomes a great enabler for industries that have an unparalleled level of miniaturization and functional density.

As we continue to shrink the world of electronics, the role of thin PCBs is set to expand exponentially.

Stay tuned for the latest thin PCB manufacturing developments that will have real potential to completely change how thin PCBs are conceptualized and used in modern electronics design. If you would like to harness the power of thin PCBs for your next project, feel free to engage a trusted PCB expert to unlock unparalleled benefits in size, weight, and performance. Learn more about the capabilities of thin PCB fabrication and the applications they are used in industry. Ensure that the Anchor Text is keyword-rich: Discover More About Thin PCB Fabrication Capabilities and Industry Applications.

We hope this comprehensive article has been able to clarify doubts about Ultrathin PCBs. If you require any other service or have any question, do not hesitate to contact us. Our dedicated staff with 18 years of experience in the electronics manufacturing field is ready to present unbeatable service to you and make your dream for Ultrathin PCB come true. Talk to us for all your custom solutions and the best customer service. We are committed to making sure you get satisfaction and are bound to offer you nothing short of the best for your Ultrathin PCBs. Get in touch with us today and let us take your project to the next level.