Rogers Printed Circuit Board (short for Rogers PCB) is a printed circuit board (PCB) manufactured using a special high-frequency material produced by Rogers Corporation. These boards are designed to meet the demanding performance requirements of high-frequency electronic devices, especially in wireless communications, microwave technology, high-speed digital signal processing, radio frequency (RF) products, and applications requiring extremely high stability and low signal loss.

What are the Main Features of Rogers Printed Circuit Board?

Rogers boards are made of a proprietary amide resin material, which gives them excellent dielectric properties, thermal stability and mechanical strength. Even in extreme working environments such as high temperature and humidity, high frequency and high speed, Rogers PCB board can maintain stable operation, showing its strong adaptability and reliability. Whether it is to improve the performance of electronic equipment, or to ensure the stability of the system, Rogers PCB board plays a vital role. Below are some main features and benefits of Rogers PCB.

- Special substrates

Unlike traditional PCB materials based on glass fiber reinforced epoxy resins such as FR-4, Rogers PCBs are ceramic filled or based on high-performance substrates such as liquid crystal polymers (LCP), for example, RO4350B, RT/duroid series, TMM series and TC series. These substrates provide excellent electrical properties, such as low dielectric constant (╬Ár) and low dielectric loss factor (Df), ensuring low signal loss and high-speed during transmission.

- High frequency performance

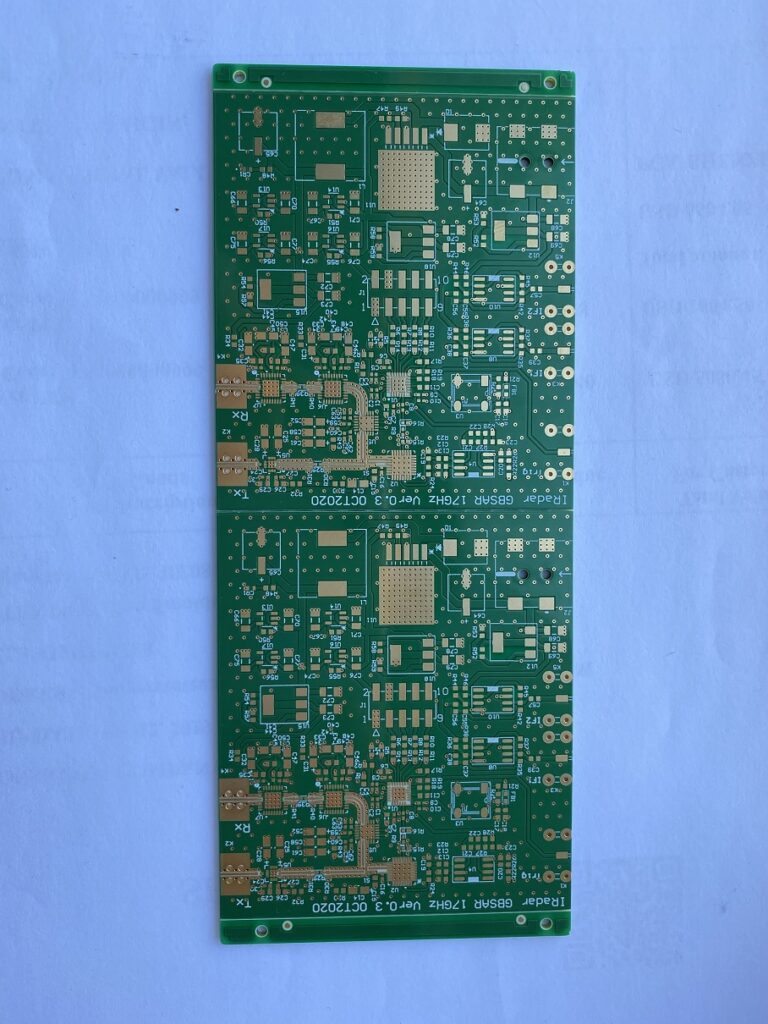

Rogers PCB is particularly suitable for high frequency applications, because its material characteristics make the circuit board can maintain extremely low signal attenuation and stable electrical performance at operating frequencies up to tens or even hundreds of GHz. This makes them excellent in radar systems, satellite communications, 5G/6G network equipment, radio frequency identification (RFID) systems, high-speed data transmission interfaces (such as USB, PCIe) and other applications.

- Temperature stability

Rogers material has excellent thermal stability and low coefficient of thermal expansion (CTE), which matches the thermal expansion rate of copper foil, helping to reduce the stress and deformation caused by temperature changes, ensuring the reliability of the circuit when working in a wide temperature range.

- Mechanical strength and heat resistance

Due to the use of high-performance composite materials, Rogers PCB usually has high mechanical strength and good high temperature resistance, and can adapt to harsh environmental conditions and heat dissipation requirements.

- Surface treatment

Rogers PCB can carry out a variety of surface treatments, such as gold plating, silver plating, organic welding film (OSP), etc., to meet the specific requirements of different applications for weldability, oxidation resistance, contact resistance, etc.

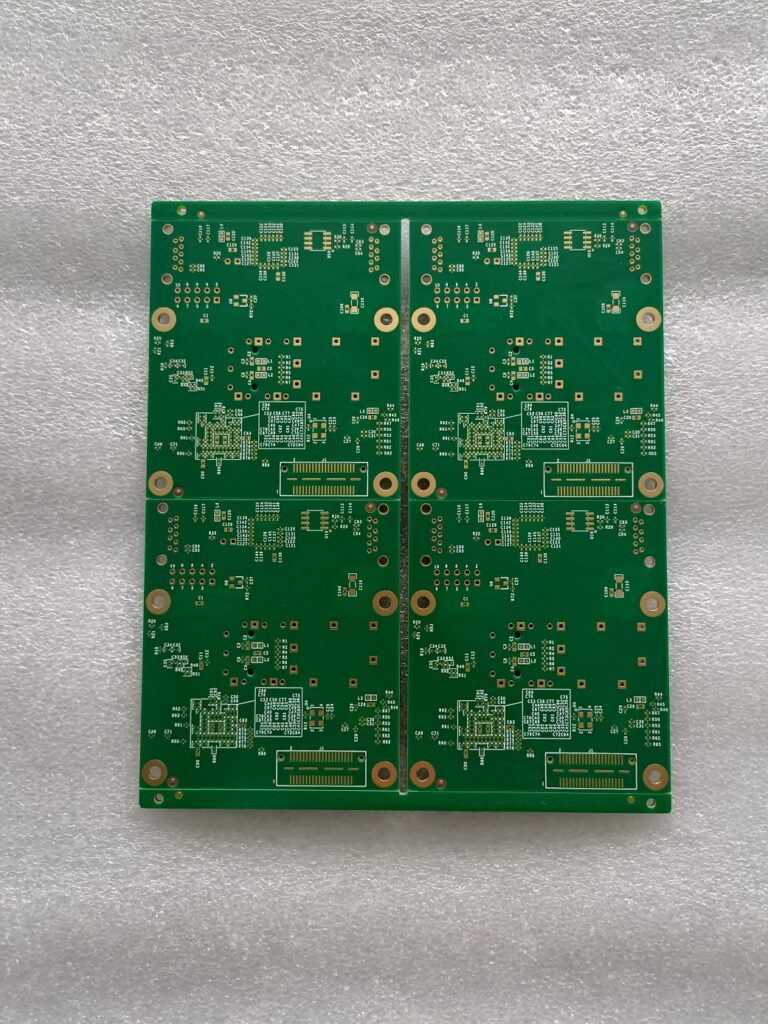

- Multi-layer structure and fine traces

Rogers PCB can be made into single-layer to multi-layer structure, support high density interconnect (HDI) design, with fine lines (such as line width/line distance up to 0.3mm or smaller) and small aperture (such as 0.3mm), suitable for complex and precise high-frequency circuit design.

- Low moisture absorption

Rogers material moisture absorption rate is very low, even in high humidity environment can maintain stable electrical performance, reduce the impact of moisture on dielectric properties, to ensure long-term reliability. In summary, Rogers printed circuit board is a high-end, professional-grade circuit board product, with its excellent high frequency characteristics, stable electrical performance, excellent temperature stability, and wide applicability, becoming the ideal choice to meet the demanding requirements of modern high performance electronic equipment and communication systems.

Why Use Rogers Printed Circuit Boards?

High frequency PCBs often need high performance with low signal losses, low electrical noise, or high board temperatures. To meet this need Rogers Corp. PCB materials are often used as they are cost effective vs. many of the alternatives. Here are some typical Applications for Rogers PCB:

All kinds of the Microwave equipment.

5G Cellular Base Station Antennas and Power Amplifiers

Automotive Radar and Sensors

RF Identification (RFID) Tags

Direct Broadcast Satellites for low noise block downconverter

Medical equipment such as monitoring instrument, cardiac pacemaker, MRI, etc.

Military and aerospace

Rogers series is often used in RF PCBs with frequencies 6+ GHz and in high heat applications that need ceramic laminates and low signal losses. It may also be used to minimize electrical noise to meet stringent performance requirements.

In our next blog from Best Technology, we are going to share more information about different material from Rogers PCB. pls follow us and if you want to know more about the Rogers PCB, warmly welcomed to visited www.bestpcbs.com or email us, it would be our great pleasure to answer all the questions for Rogers PCB.

Tags: rogers pcb