Best technology engaging in the PCB manufacturing and PCB design for more than 17 years. With a strong R&D team, we can provide customers with fast and valued PCB design solutions. Here is one of our industrial motherboard design & industrial PCB case sharing for your reference. If you want to get your own industrial PCB design, welcome to contact us.

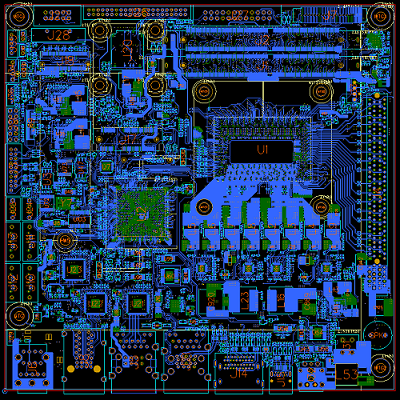

A mITX architecture industrial control motherboard

[1] Intel Xeon E3, Core™ i7/i5, Celeron G3900E processors

[2]:2x DDR4 SODIMM 2133 MHz (up to 32 GByte)

[3]:4x SATA Gen 3.0

[4]:1x PCIe x16 (Gen 3)

[5]:2x USB 3.0 (Internal) + 1x USB 3.0 (Client) + 2x USB 3.0 (Rear I/O) + 2x USB 2.0 (Rear I/O) +

2x USB 2.0 (Front Header) + 1x USB 2.0 (mPCIe)

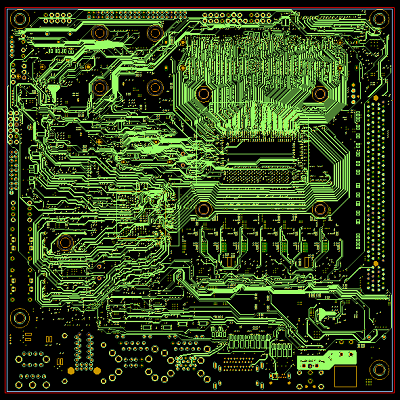

Industrial PCB Design Considerations

- Control the length of the circuit: Minimize the length of the circuit, especially the key signal lines, to reduce signal attenuation and delay.

- Avoid sharp angles and right angles: Right angles and sharp angles should be avoided when wiring, and rounded or 45 degree angles should be used as far as possible to reduce signal reflection and impedance discontinuity.

- Line width: Determine the line width according to the current size and thermal requirements to ensure the reliability and stability of the circuit.

- Inter-layer wiring: Rational use of multi-layer PCB inter-layer wiring, such as the signal line on the inner layer, power and ground wire on the outer layer.

- Impedance control: For high-speed signals, it is necessary to control the line impedance to ensure signal integrity, and carry out impedance matching design if necessary.

- Avoid cross and parallel wiring: Try to avoid cross and parallel wiring of signal lines to reduce crosstalk and electromagnetic interference.

Contact us if you have any questions and inquiry about industrial PCB design projects.

Tags: pcb design