Copper Clad Laminate as a base material of FR4 PCB, serving as a key part in the building of printed circuit board. Understanding what Copper Clad Laminate is, its benefits, types, and manufacturing process is essential for anyone who involved in the electronics industry. This article aims to provide a comprehensive overview of copper clad laminate material, and hope everyone in the PCB industry be interested in it.

What is copper clad laminate?

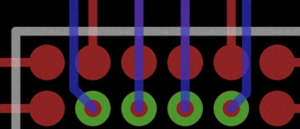

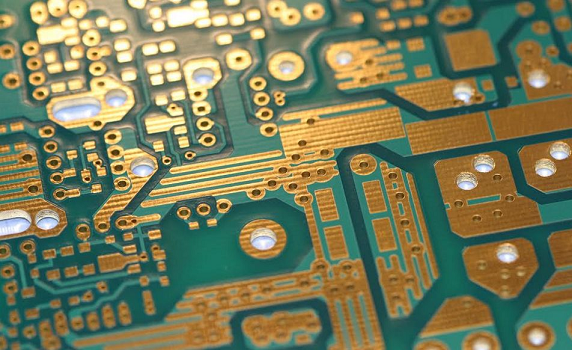

Copper Clad Laminate, short for CCL, is an electronic glass fiber cloth or other reinforcing material dipped in resin, one or both sides covered with copper foil and made of a plate-like material, referred to as copper clad plate. It also called “Core” when used in the multi-layer PCB designs. Through the different process like etch, drill or copper plating, we can generate different patterns, layouts onto the surface of the CCL, and then form a circuit board that we saw in the electronics.

CCLs provide the necessary support and electrical insulation in an electronic device, while also facilitating the pathways for electrical currents through the copper foil. So, in another word, the performance, long-term reliability and stability of the PCB depend on the CCL to a large extent.

What are the types of copper clad laminates?

Generally speaking, copper clad laminate can be divided into two main types according to its mechanical properties, they are – rigid copper clad laminate and flexible copper clad laminate. Here we listing the detailed types of CCL.

- Rigid copper-clad laminate

a. According to different insulation materials and structures: organic resin clad copper laminate, metal clad copper laminate, ceramic clad copper laminate.

b. According to the thickness of the plate: conventional copper-covered laminate and thin copper-covered laminate. The thickness less than 0.5mm (doesn’t include the copper foil) is called thin CCL.

c. According to the reinforcement material used: electronic glass fiber cloth base copper foil board, paper base copper foil board and composite base copper foil board.

d. According to the insulating resin used, such as epoxy resin copper-coated foil board, polyester resin copper-coated foil board and cyanate resin copper-coated foil board.

e. Special rigid copper clad plate, according to the flame-retardant grade and some special properties.

- Flexible copper clad laminate

a. polyester types (flame retardant and non-flame retardant)

b. polyimide type (flame retardant, non-flame retardant)

c. Extra thin electronic glass fiber cloth copper foil laminate

What’s the main composition of copper clad laminate?

A normal copper clad laminate mainly consists of copper foil and some auxiliary materials. These materials make the CCL conductive and be used as the core material of the circuit board. Here we would like to explain these compositions in details:

- Copper foil

Copper foil is one of the main raw materials for manufacturing copper clad laminate, and it is a very pure metal material with excellent electrical conductivity. The thickness and purity requirements of the copper clad foil are very high, usually between 18-70μm, and the purity is more than 99.8%. In the manufacturing process of CCL, copper foil is used as a conductive layer to transfer current from one electronic component to another. It also has good plasticity and ductility, and can be bent, stretched and formed as needed without adversely affecting electrical conductivity. In addition, the corrosion resistance of the copper foil is also very good, which can resist the erosion of chemical substances, ensuring that the CCL can work properly in a variety of environments.

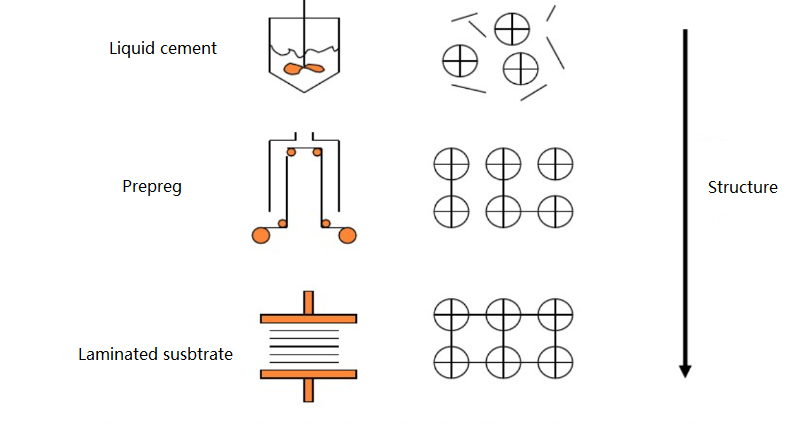

- Auxiliary materials like resin and adhesive

In addition to copper foil and copper clad foil, the production of CCL also involves some other auxiliary materials, such as adhesives and reinforcing materials. Among them, the adhesive is mainly used to fix the copper foil and copper clad foil on the substrate. The selection of adhesives should take into account their adhesion and high temperature resistance to ensure that the copper foil and copper clad foil can be firmly bonded to the substrate. Reinforcement materials are mainly used to improve the mechanical strength and bending resistance of CCL. Common reinforcement materials include glass fiber cloth and polyimide film.

CCL Manufacturing Process

The manufacture of CCL is a meticulous process; therefore, it includes many accurate steps:

- Prepare substrate – the commonly used substrate is fiberglass cloth impregnated with epoxy resin, which is non-conductive material and has good insolation and mechanical properties, then cured to get the correct mechanical and thermal characteristics.

- Surface treatment – this is a surface cleaning and grinding process to achieve a clean and roughness surface of the substrate, resulting a good adhesion between the copper foil and substrate.

- Copper Foil Lamination – lamination of copper foil onto the prepared substrate is done by temperature and pressure quickly and smoothly to obtain a stable bond. This is a lamination process of single layer CCL, if you want a multi-layer CCL, coating adhesive on each layer and then laminate in the press machine, then making them in a whole product.

- Cutting and Trimming – the need for the dimensions drives the sheets to be cut and trimmed into a desired size.

- Quality Checking: A thorough quality check follows to confirm that the CCL matches industry requirements on thickness, adhesion, and electrical properties.

Where is the Copper Clad Laminate uses?

CCL has a widely applications thus constituting a critical element for numerous electronic devices and systems, the typically are including:

- Consumer electronics like cell phones, laptops, and tablets

- Automotives including infotainment and engine control units

- Industrial equipment like common test equipment

- Telecommunications such as networking equipment and communication devices

- Medical device, for example: imaging system, diagnostics

If you are looking for a company that can advance and improve your electronic circuit, then Best Technology is the right choice for you. Best Technology is a one-stop solution providers in China with extensive years of experience in high quality PCB and PCBA manufacturing. We have certificated by ISO9001, ISO13485, IATF16949 to make you no worry about the quality. Contact us right now to get your quotations!

Tags: ccl, copper clad laminate