The led light circuit board, also called the LED circuit board, is actually the abbreviation of the printed circuit board (PCB). PCB is a stable carrier of electronic components, which not only realizes electrical connection, but also plays a supporting role. In LED lamps, the PCB board integrates LED components, and through this integrated PCB board, the LED lamp can realize its function. The driving circuit of the LED lamp, such as constant voltage drive, constant current drive, PWM drive, etc., are all integrated on this small circuit board, which is necessary to light up the LED lamp beads. Therefore, it can be said that the circuit board of the LED lamp is the printed circuit board inside it, which is responsible for converting electrical energy into visible light, and controlling the brightness and performance of the LED through different driving methods.

Customized process of led light circuit board

- Support small and medium batch orders of 1-14 layers, consult customer service for more layers;

- Can do HDI blind buried hole process;

- The board uses Jiantao A-grade board (KB-6164), which can be made into halogen-free board;

- The maximum size can be one meter;

- Various ink colors such as pink, transparent, purple, etc.;

- Support copper thickness of 10oz, hole copper 35μm;

- Multi-layer board can be customized with pressing structure;

- Support multi-level impedance matching;

- Board edge copper package, two-color ink, plug hole, countersunk hole, square groove, stepped hole, stepped groove, nickel palladium gold and other special processes;

- PCBA can be pasted in one set, single and double sides can be pasted;

led light circuit board

What fields can led light circuit board be applied in?

PCB LED lamp has excellent energy efficiency, low cost and maximum design flexibility, so it can be incorporated into many lighting applications.

Telecommunications: LED indicators and displays are always used in telecommunications equipment due to the surrounding machinery, and they have great heat transfer capabilities. Therefore, aluminum-based LED PCBs play an important role in their applications.

Automotive: Aluminum PCB LEDs are also used in the indicator lights, brake lights, and headlights of automobiles, among other applications. There are factors that make aluminum PCBs ideal in the automotive industry, such as durability and competitive pricing.

Computers: LED displays and indicator lights are becoming increasingly popular in computer applications. Aluminum PCB LEDs are an ideal solution due to the heat sensitivity of computer machinery. In addition to LED applications, aluminum PCBs are also used in computer components such as power supply units and CPU boards due to their ability to dissipate and transfer heat.

Medical: Lighting tools used in surgical procedures and medical examinations often use high-power LED lights, which often use aluminum PCBs, mainly because of the durability and heat transfer capabilities of aluminum PCB LEDs – this ensures that medical equipment operates properly, regardless of the number of patients that are cycled through the medical office. In addition to lighting tools, medical scanning technology also often uses aluminum PCBs.

What fields can LED PCB be applied in?

Advantages of led light circuit board

Lower power consumption: Replacing incandescent lamps with LED lamps can reduce power consumption by more than 80%.

Longer life: The service life of LEDs can generally exceed 20,000 hours, and they can be used around the clock for 3 years, which is 25 times longer than incandescent lamps. Not only can it save costs, but it also reduces the frequency of replacement.

Higher efficiency: Incandescent lamps release more heat. LED lamps can reduce it by up to 20%. This means that while using more powerful LED lamps, unnecessary heating can be reduced.

Smaller size: Due to their small size, LED lamps can have various sizes and can be used in different places. Manufacturers can add LEDs to anything, whether it is electronic equipment or cars, and even traffic lights and signs on the road.

Environmental protection: Compared with other bulbs, LED lamps do not contain mercury. Therefore, LEDs have less impact on the environment and are easier to handle.

LED is the abbreviation of light-emitting diode, which is a semiconductor diode. LEDs are soldered to a printed circuit board and equipped with a chip that generates light through electrical connections. A heat sink and a ceramic base are used to connect the chip. Undoubtedly, LED PCB is the core of LED lighting. An LED PCB tends to generate a lot of heat, but it is difficult to cool it by traditional methods. Metal core PCB is widely used in LED applications due to its strong heat dissipation ability, especially aluminum is often used in the production of PCB for LED lamps. Usually, aluminum PCB contains a thin layer of thermal conductive medium material, which can transfer and dissipate heat much more efficiently than traditional rigid PCB.

Why led light circuit board use mcpcb

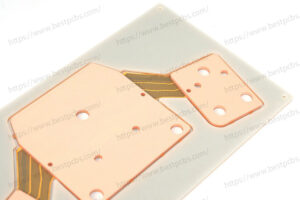

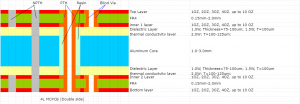

Aluminum substrate is a metal-based copper-clad board with good heat dissipation function. Generally, a single-sided board consists of three layers, namely circuit layer (copper foil), insulation layer and metal base layer. There are also designs for high-end use as double-sided boards, with the structure of circuit layer, insulation layer, aluminum base, insulation layer and circuit layer. Very few applications are multi-layer boards, which can be made of ordinary multi-layer boards with insulation layer and aluminum base.

LED aluminum substrate is PCB, which also means printed circuit board, but the material of the circuit board is aluminum alloy. In the past, our general circuit board material was glass fiber, but because LED generates more heat, the circuit board used for LED lamps is generally aluminum substrate, which can conduct heat quickly. The circuit boards used for other equipment or electrical appliances are still glass fiber boards!

How are LED patches installed on PCB boards?

Use double-sided PCB board, patch LED on the front, and drive power circuit on the back. LED can be designed into a circle shape, through metallized holes to the back, there are plenty of places to handle these leads

On the corresponding pads of PCB board, brush tin, use patch machine to apply it, and then reflow soldering, it is on, but in actual operation, you need to pay attention to many problems, anti-static, equipment quality, etc.

Tags: LED, LED aluminum pcb, LED circuit board, LED flexible PCB, LED light