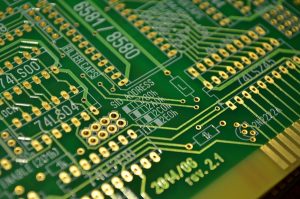

Heavy Copper Board does not have a set of definition per IPC. According to PCB industry, however, peopel generally use this name to identify a printed circuit board with copper conductors 3 oz/ft2 – 10 oz/ft2 in inner and/or outer layers. And Extreme heavy copper PCB refers to 20 oz/ft2 to 200 oz/ft2 printed circuit board.

Heavy copper normally used for a various products but not limited to: high power distribution, heat dissipation, planar transformers, power convertors, and so on.

Generally, the thick copper plate is about 3oz, and the larger current is 3oz~6oz. To achieve 15 ounces, the requirements for process and manufacturers are more stringent. Best provides 3-15oz 1-99 layers of PCB. It is a professional PCB manufacturer with 18 years of experience, providing one-stop PCB and PCBA services from design, manufacturing to after-sales.

Common copper foil thicknesses have the following options:

- 1 oz (35 μm): This is the most common and standard copper foil thickness, widely used in general electronic product manufacturing. It has good electrical and thermal conductivity.

- 2 oz (70 μm): This thickness of copper foil is usually used in circuits that require higher current carrying capacity, such as power amplifiers, high-power LEDs, etc.

- 0.5 oz (18 μm): This thinner copper foil thickness is suitable for some light and small electronic products, such as electronic watches, mobile phones, etc.

- Other thicknesses: According to special needs, you can also choose copper foil of other thicknesses, such as 3 oz, 4 oz, etc.

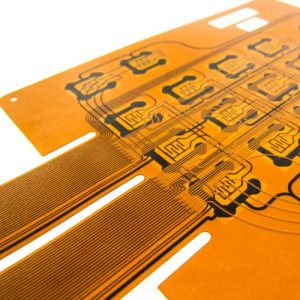

What is copper foil

Copper foil is a cathodic electrolytic material, a thin, continuous metal foil deposited on the substrate layer of the circuit board, which serves as the conductor of the PCB. It is easy to adhere to the insulating layer, accept the printed protective layer, and form a circuit pattern after corrosion. The copper mirror test is a flux corrosion test, using a vacuum precipitation film on a glass plate. Copper foil is made of copper and a certain proportion of other metals. Copper foil generally has two types: 90 foil and 88 foil, that is, the copper content is 90% and 88%, and the size is 16*16cm.

How thick is the PCB copper foil

The commonly used international PCB copper foil thicknesses are: 35um, 50um, and 70um.

Generally, the thickness of copper foil (copper cladding) of single-sided and double-sided PCB boards is about 35um (1.4mil), and the other specifications are 50um and 70um.

The surface thickness of multilayer boards is generally 35um=1oz (1.4mil), and the inner layer is 17.5um (0.7mil). 70% of circuit boards use a copper foil thickness of 35um, which mainly depends on the purpose of the PCB and the voltage and current of the signal; in addition, for PCBs that need to pass large currents, some will use 70um copper thickness, 105um copper thickness, and rarely 140um, etc. The copper foil thickness is usually expressed in oz (ounces). 1oz refers to the thickness of 1oz of copper evenly covering an area of ââ1 square foot, which is about 1.4mil. It uses the weight per unit area to express the average thickness of the copper foil.

Expressed in formula, that is, 1oz=28.35g/ FT2 (FT2 is square feet, 1 square foot = 0.09290304 square meters).

Different uses have different copper foil thicknesses,

- Ordinary 0.5oz, 1oz

- 2oz, mostly used in consumer and communication products.

Thick copper products above - 3oz are mostly used for large currents, such as high-voltage products and power boards!

Copper foil thickness (track width) affects the current size. Although there is a formula that can directly calculate the current load capacity of copper foil, it is not so simple when actually designing the circuit. Therefore, safety should be fully considered when designing.

How thick is 2 oz of copper for PCB?

In the PCB industry, 1OZ means the thickness of 1OZ of copper evenly laid on an area of ââ1 square foot (FT2). It uses the weight per unit area to express the average thickness of the copper foil. Expressed in formula, 1OZ=28.35g/FT2 (FT2 is square feet, 1 square foot=0.09290304 square meters).

First, we know that the density constant of copper and the conversion formula of related units are as follows:

1 cm = 10 mm; 1 mm = 1000 um

1 FT2â929.0304cm2

According to the mass calculation formula m=ÏÃV(volume)=ÏÃS(area)Ãt(thickness), we know that the weight of copper foil divided by the density and area of ââcopper is the thickness of copper foil!

So, t=28.35÷929.0304÷8.9cmâ0.0034287cm=34.287umâ34.287÷25.4milâ1.35mil

Copper thickness 1.OZ(0.035mm) Copper thickness 1.5OZ(0.05mm) Copper thickness 2.OZ (0.07mm)

What are the materials of PCB board

FR-1ââphenolic cotton paper, this base material is commonly known as bakelite (more economical than FR-2)

FR-2ââphenolic cotton paper

FR-3ââcotton paper, epoxy resin

FR-4ââglass cloth, epoxy resin

FR-5ââglass cloth, epoxy resin

FR-6ââmatte glass, polyester

G-10ââglass cloth, epoxy resin

CEM-1ââcotton paper, epoxy resin (flame retardant)

CEM-2ââcotton paper, epoxy resin (non-flame retardant)

CEM-3ââglass cloth, epoxy resin

CEM-4ââglass cloth, epoxy resin

CEM-5ââglass cloth, polyester

AINââaluminum nitride

SICââsilicon carbide

Tags: heavy copper pcb, PCB