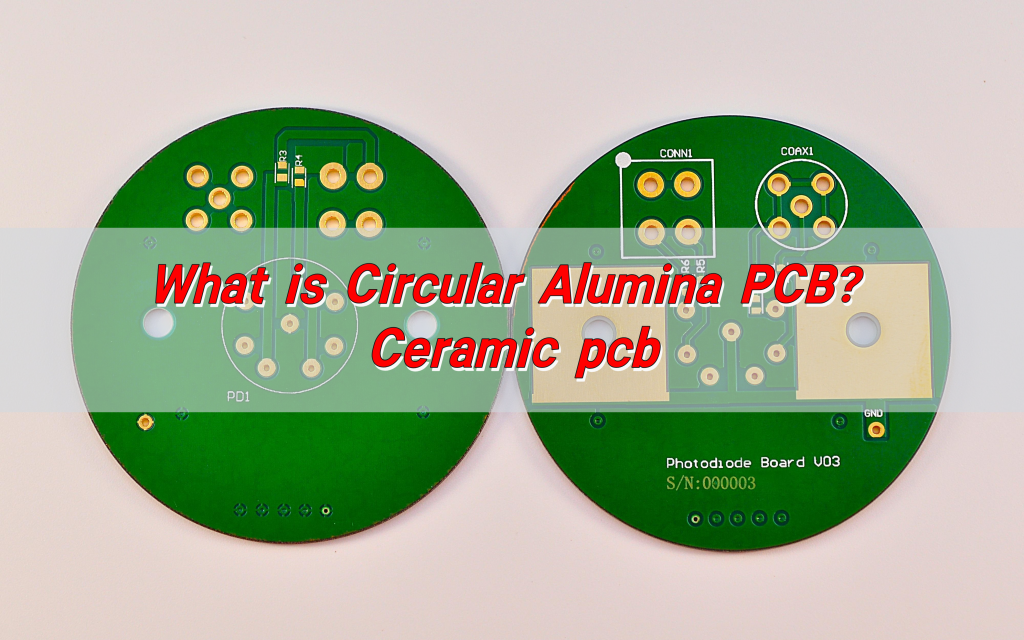

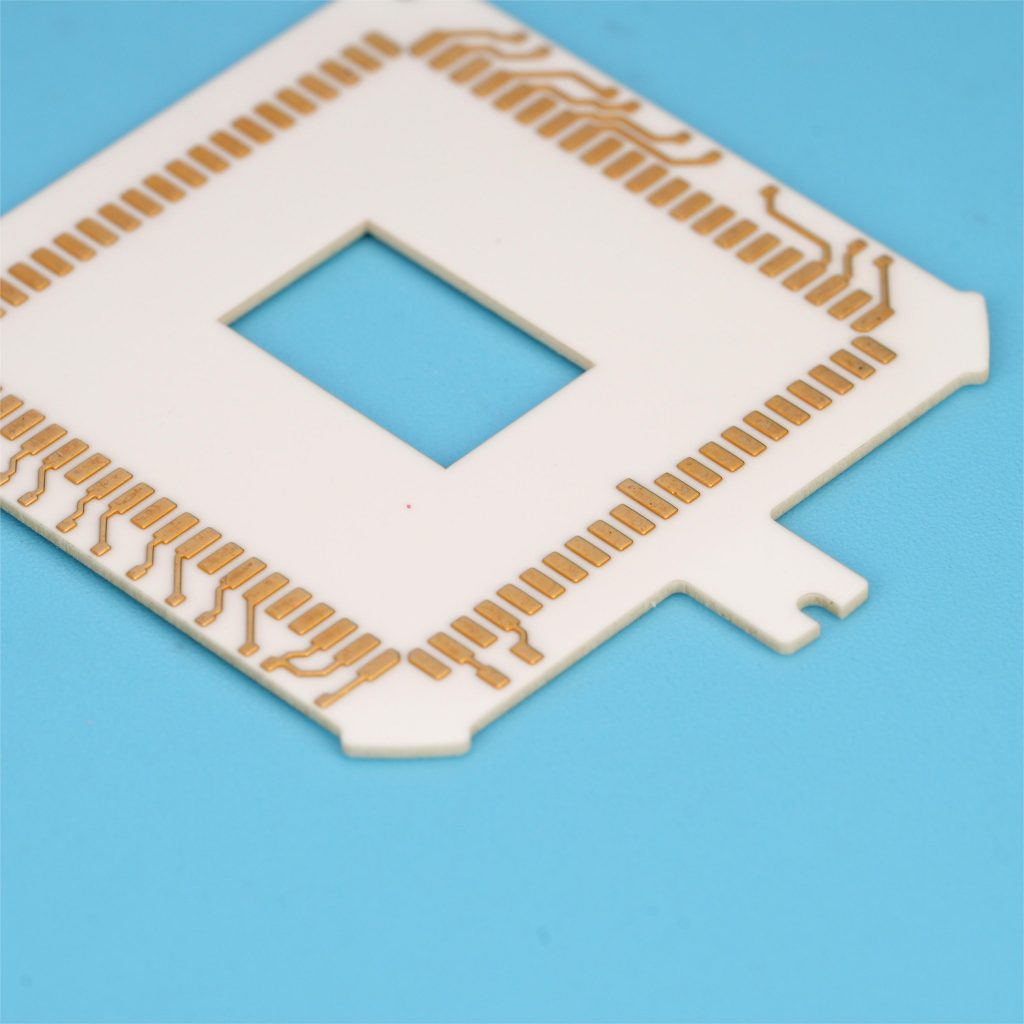

Ceramic circuit board has almost completely integrated into our daily life, and it is filled with all kinds of electronic products we use every day. However, the production of ceramic circuit board is not so simple. The ceramic material itself is brittle, and it is easy to break in the process of through-hole, which easily leads to the scrapping of the whole board. However, this problem can’t stop the development of ceramic circuit board, and its position in the electronic industry is becoming more and more important. So do you know how ceramic circuit board was born?

History of ceramic circuit board

The history of ceramic circuit boards can be traced back to the early 1950s. At that time, with the appearance of transistors, single-sided ceramic circuit boards were developed centering on the United States. The main manufacturing method in this period is the direct etching of copper foil as the mainstream. From 1953 to 1955, Japan made paper-based phenolic copper foil substrates from imported copper foil for the first time, and it was widely used in radios and other aspects. Subsequently, the emergence of professional circuit board manufacturers in Japan made the manufacturing technology of single panel progress rapidly, and ceramic circuit boards also entered the development stage.

In the development process of ceramic circuit board, it has experienced the transformation from single panel to double panel. Compared with single panel, double panel has wiring on both sides, and leads on both sides are connected through guide holes, which is suitable for more complex circuits. There is more flexibility in the design of double-panel circuits, because the wiring can be carried out on both sides and staggered with each other, which increases the complexity of circuit design but also improves the performance and function of the circuit.

What are the problems faced by traditional pcb circuit boards?

With the increasing variety of electronic products, it is necessary to use the circuit board in assembly, but the first problem that has to be faced is the heat dissipation of the circuit board. With the continuous expansion of the application scope of VLSI and the development trend of SMT, the design of organic laminated PCB is facing the challenge of heat dissipation, which is because the thermal conductivity of most ordinary PCBs is low. However, the thermal conductivity of ceramics is 90 times that of epoxy glass fiber, and it has excellent conduction cooling effect. Moreover, components on ceramic PCB usually have a lower junction temperature than ordinary PCB.

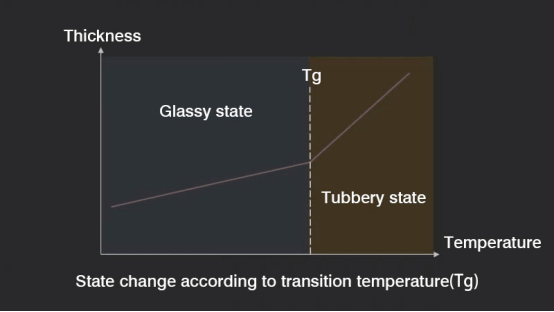

Secondly, there is another problem that needs to be faced, which is the CTE compatibility challenge. SMT technology, which became popular in the first half of 1980s, is affecting the whole electronic assembly industry. Because SMT technology directly welds electronic components on both sides of PCB, compared with THT (through hole technology), SMT technology has lower cost, higher reliability and easier automation, which can reduce the circuit size by five-sixths. Some reliable packages, such as LCC (leadless chip carrier), are very compatible with SMT requirements, but they usually cannot withstand the challenges brought by thermal cycling. Therefore, LCC is questioned from package reliability to on-board interconnection, because the CTE (coefficient of thermal expansion) incompatibility between LCC and PCB materials leads to welding failure. Therefore, ceramic PCB came into being. Ceramic PCB can provide the best solution to overcome thermal cycle failure, because they share compatible CTE with leadless ceramic chip carriers, and have higher thermal conductivity, higher stability and inertness.

Characteristics of ceramic circuit board

Compared with the traditional pcb based on phenolic resin (FR-4), glass fiber cloth (GPP), polytetrafluoroethylene (PTFE), epoxy glass fiber and polyimide, ceramic circuit board has superior thermal conductivity, high mechanical strength and durability, excellent electrical insulation and high dielectric strength.

With the development of multi-function, miniaturization, speediness and large-scale electronic equipment, stricter requirements are put forward for the durability, thermal conductivity, dielectric constant and electrical insulation of ceramic PCB. It can be predicted that the demand for ceramic PCB with aluminum nitride, alumina and glass ceramics as substrate materials will be increasing, and the market for ceramic circuit boards will be wider and wider.

What are the types of ceramic circuit boards?

At present, the common types of ceramic circuit boards are HTCC, LTCC, DBC, DPC, AMB, TFC (thin film ceramic board) and TPC (thick film ceramic board).

1. HTCC is an early developed technology. However, due to the high sintering temperature (1300~1600℃), the selection of electrode materials is limited, and the manufacturing cost is relatively expensive, which makes the development of HTCC slow.

2. Although LTCC reduces the co-firing temperature to about 850℃, it has the disadvantage that dimensional accuracy and product strength are not easy to control.

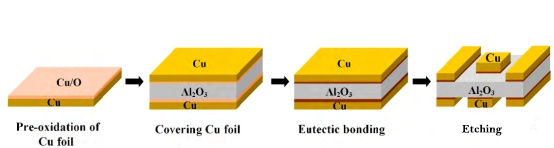

3. DBC combines Al2O3 with Cu plate by high temperature heating. Its technical bottleneck is that it is not easy to solve the problem of micro-pores between Al2O3 and Cu plate, which makes the mass production energy and yield of this product greatly challenged.

4. DPC technology is to deposit Cu on Al2O3 substrate by direct copper plating technology. Its technology combines material and thin film technology, and its products are the most commonly used ceramic heat dissipation substrate in recent years. However, its ability of material control and process technology integration is high, which makes the technical threshold for entering DPC industry and stable production relatively high. DBC&DPC is a professional technology that has only been developed and matured in recent years in China and can be mass-produced.

5. AMB ceramic copper clad laminate adopts AMB active brazing process, and the bonding force of copper layer is higher than DPC, which is above 18n/mm and as high as 21 N/mm.. AMB ceramic copper clad laminate usually has high bonding force, and the copper is usually thick, ranging from 100 μ m to 800 μ m, and it is rarely used for wiring or punching. Even if there are wires, it is very simple and the spacing is relatively wide.

6. TFC thin-film ceramic substrate generally adopts sputtering process to directly deposit metal layer on the surface of ceramic substrate. If photolithography, development, etching and other processes are assisted, the metal layer can also be patterned and prepared into lines. Because the deposition speed of sputtering coating is low (generally less than 1um/h), the thickness of the metal layer on the surface of TFC substrate is small (generally less than 1um), and ceramic substrates with high graphic accuracy (line width/line spacing less than 10um) can be prepared. It is mainly used for packaging small current devices in the field of laser and optical communication.

7. TPC thick film ceramics is a method of forming conductive lines and electrodes by screen printing, directly depositing slurry on the substrate and sintering at high temperature. This method is suitable for most ceramic substrates. After high temperature sintering, the material will form a firmly adhered film on the ceramic circuit board, and after repeated for many times, it will form a circuit with multi-layer interconnection structure containing resistance or capacitance. The advantage of this technology is that the process is simple, but the disadvantages are obvious: the conductors are gold paste and silver paste, limited by the size of conductive paste and screen, the minimum wire width of the product is difficult to be less than 100μm, and it is impossible to make three-dimensional graphics, so it is not suitable for the production of fine circuit boards.

Where is the ceramic circuit board used?

1. LED lighting

2. Power electronics

3. Aerospace

4. Automotive Electronics

5. Medical equipment

6. high frequency communication

7. chemical equipment

8. industrial electronics

Ceramic circuit boards are widely used in all walks of life because of their unique properties, especially in the electronic circuit industry.

Since its birth, ceramic circuit boards have been widely used. With the development of electronic industry, in order to adapt to the application of special industries, the types of ceramic circuit boards have become more and more diverse. As a professional manufacturer of ceramic circuit boards, BEST Technology is committed to providing high-quality products and comprehensive technical support. For different types of ceramic circuit boards, BEST Technology also has professional equipment and personnel to produce them. Choose a powerful manufacturer of ceramic circuit boards, and you will have no worries.

Tags: ceramic circuit board