What is a Drone Circuit Board?

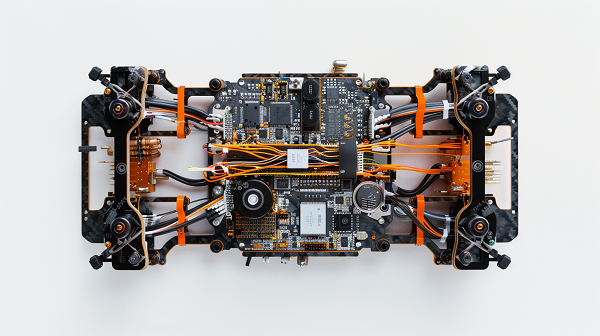

A drone circuit board refers to the electronic component board installed in a drone that controls and manages its various functions. It serves as the core control system of the drone, similar to how a brain functions in the human body. The drone circuit board controls all operations, including flight, photography, and video recording. It is the central system that coordinates all activities.

Depending on different functions and application scenarios, drone circuit boards can be classified into various types, such as flight control boards, video transmission boards, and power control boards. Among these, the flight control board can be considered a type of drone circuit board but is not equivalent to it. The flight control board mainly controls parameters such as flight direction, altitude, and speed, and adjusts the drone’s posture to ensure stable flight. The drone circuit board, however, not only controls flight but can also implement auxiliary functions such as GPS positioning and image transmission.

What Board is Used in Drones?

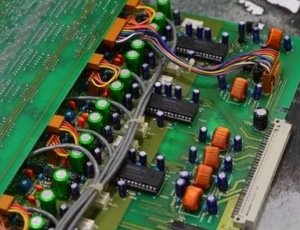

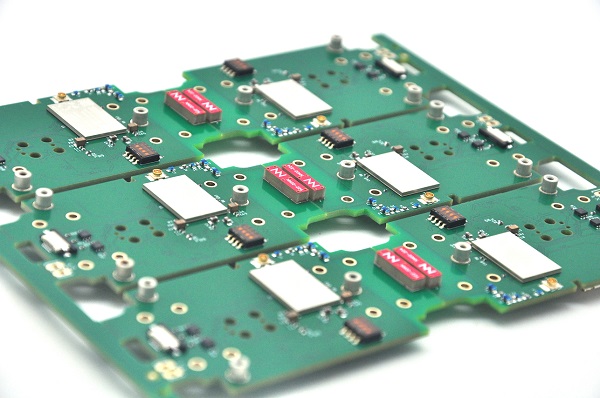

In drone design, the two most common types of circuit boards are rigid-flex boards and traditional PCB boards. Rigid-Flex PCB is a hybrid type of PCB that combines rigid and flexible circuit boards. It allows the board to bend and fold in tight spaces, which is particularly useful for compact drones that require a highly integrated design. Moreover, rigid-flex boards are lightweight and thin, which is advantageous for drone designers looking to enhance flight time and stability.

Traditional PCB Boards are another common type of circuit board used in drone design. These boards have strong mechanical strength, making them suitable for the core control units in drones, such as flight control boards and ESC boards (Electronic Speed Controllers).

Below are the main types of circuit boards commonly found in drones:

Control Circuit Board

The control circuit board is one of the most important boards in a drone. It typically consists of the main control chip, sensors, and electronic speed controllers (ESC). The main control chip acts as the brain of the drone, receiving wireless signals and controlling the flight posture and movement based on user commands. Sensors can detect the drone’s position and motion in real-time, ensuring stable flight control. The ESC adjusts the motor speed and direction, which directly impacts the drone’s flight.

Power Supply Circuit Board

The power supply circuit board is responsible for providing power to the drone, ensuring proper voltage and current. It must prevent issues like overcurrent, overvoltage, and overheating to maintain the drone’s performance.

Navigation Circuit Board

The navigation circuit board determines the drone’s position and direction, with the GPS module as the core component. GPS helps obtain satellite signals, calculating important information such as latitude, longitude, and altitude, to ensure precise navigation and positioning. The board may also include other sensors like barometers, gyroscopes, and accelerometers to enhance navigation accuracy.

Communication Circuit Board

The communication circuit board typically includes WiFi, Bluetooth, and 4G/5G modules, which allow the drone to connect with ground control stations or user devices for data transmission, remote control operations, and video streaming.

Why Use a Drone Circuit Board?

Besides the central chip, drone circuit boards serve many critical functions, such as power management and signal transmission. Let’s take a closer look at their functionality:

Power Management

The power management chip on a drone circuit board controls and regulates the power supply. Unlike regular circuit boards, the power management module in drones must be efficient, low-power, and lightweight. Since drones often need to fly for hours, improper design of the power management module can severely impact flight time and energy utilization.

Collecting data

The sensor chip on the drone circuit board is responsible for collecting data, such as GPS location, barometric pressure, and posture. The sensor chip processes data from wireless sensors and transmits it to the control chip for decision-making.

Control the drone

The control chip is the most vital part of the drone circuit board, managing and coordinating all aspects of the drone’s operation, including GPS navigation, servos, and motors. The microprocessor in the control chip uses algorithms to control flight while processing real-time sensor data.

Data Transmission

When capturing aerial photos or videos, the drone needs to send the recorded data to ground devices. The data transmission chip on the drone circuit board ensures that this information is transmitted to ground equipment. Many drones also support wireless network connections for seamless communication.

How to Make a Drone PCB?

To make a drone PCB, you’ll need to prepare the following materials:

- STM32F405RGT6 microcontroller, which is stable and suitable for various drone applications.

- 2.4G CC2500 wireless module based on the UART protocol for data communication with the remote control.

- Sensors like accelerometers, gyroscopes, magnetometers, barometers, GPS, etc., to provide sensor fusion for precise drone control.

- Power Module

- Other components including resistors, capacitors, diodes, voltage regulators, and other basic circuit components.

Here is the way to create the drone PCB step by step:

1. Design

You can use PCB software to design the schematic and PCB layout, determining key parameters like circuit connections and component placement.

2. Printing and Etching

Print the designed circuit board pattern onto transparent stickers and attach them to copper sheets. After etching and removing the stickers, the circuit board will be ready.

3. Soldering

Solder the components onto the circuit board. It’s essential to leave adequate pads for soldering during the design phase.

4. Testing

Test the soldered circuit board to ensure normal functioning of the circuits.

What Should We Consider When Designing a Drone PCB?

- Make sure enough power, ground, and data lines are allocated to each component to avoid signal interference and noise.

- Take measures to protect components from static electricity during soldering.

- Write clear and standardized comments in your program for easier modifications and debugging later.

- Double-check that the board’s connections are in the correct order to prevent damage to the control board.

Is a Fuse Board the Same As a Distribution Board?

No, a fuse board and a distribution board serve different purposes in a drone’s electrical system.

Fuse board is designed to protect your components from power surges or short circuits. It contains fuses that blow if too much current flows through them, cutting off power to prevent damage.

Distribution board is simply distributes power from the battery to different components of the drone, such as the ESCs and flight controller. It doesn’t have the protective features of a fuse board.

In some designs, both can be combined into one board, but their functions remain distinct.

How can I Increase my Drone Power?

Increasing your drone’s power can improve performance, allowing it to carry more weight or fly faster. You can use below ways to increase the power:

- Upgrade motors

- Increase battery capacity

- Use better propellers

- Optimize power distribution

Tags: Drone dircuit board, Drone PCB