What is copper clad laminate?

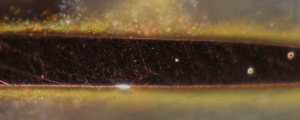

Copper clad laminate (CCL) is a plate-like material made by impregnating electronic fiberglass cloth or other reinforcing materials with resin, covering one or both sides with copper foil and hot pressing. It is referred to as copper clad laminate.

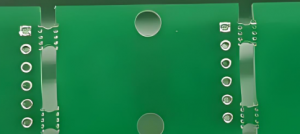

Printed circuit boards of various forms and functions are selectively processed, etched, drilled and copper-plated on copper clad laminates to make different printed circuits.

It mainly plays the role of interconnection, insulation and support for printed circuit boards, and has a great influence on the transmission speed, energy loss and characteristic impedance of signals in the circuit. Therefore, the performance, quality, processability, manufacturing level, manufacturing cost and long-term reliability and stability of printed circuit boards depend to a large extent on copper clad laminates.

What is flexible copper clad laminate?

Flexible copper clad laminate is a special copper clad laminate, which is composed of a flexible insulating base film and a metal foil. It is usually composed of three different materials: copper foil, film, and adhesive, forming a three-layer flexible copper clad laminate.

If there is no adhesive in the flexible copper clad laminate, it is called a two-layer flexible copper clad laminate. Flexible copper clad laminate is formed by bonding copper foil to one or both sides of a flexible insulating material such as polyester film or polyimide film through a certain process.

This material is widely used in the electronics industry, especially in electronic devices that need to bend, move, and stretch, such as laptops and digital cameras. The characteristics of flexible copper clad laminate include thinness, lightness, and flexibility, which give it obvious advantages in high-density wiring, light weight, and small size.

In addition, flexible copper clad laminate plays an important role in the manufacturing process of electronic products. Its performance directly affects the conductivity, insulation, and support of the PCB circuit board, thereby affecting the overall performance and cost of the product.

What are the performance requirements for copper clad laminates?

- Appearance requirements: The appearance of the copper clad laminate should meet certain standards, including that the metal foil surface should not have pits, scratches, resin spots, wrinkles, pinholes, bubbles, white silk and other defects.

- Dimension requirements: Including the board size, length, width, diagonal deviation, warpage, etc. should comply with the regulations. The nominal board size and allowable deviation, nominal thickness and deviation, verticality, warpage, etc. of aluminum-based copper clad laminates also have specific requirements23. 3. Electrical performance requirements: Including dielectric constant (Dk), dielectric loss tangent (Df), volume resistance, surface resistance, insulation resistance, arc resistance, dielectric breakdown voltage, electrical strength, comparative tracking index (CTI), ion migration resistance (CAF), etc.

- Physical performance requirements: including dimensional stability, peel strength (PS), bending strength, heat resistance (thermal stress, Td, T260, T288, T300), punching, etc.

- Chemical performance requirements: including flammability, solderability, chemical resistance, glass transition temperature (Tg), Z-axis thermal expansion coefficient (Z-CTE), dimensional stability, etc.

- Environmental performance requirements: including water absorption, pressure vessel boiling test, etc., to ensure that the copper clad laminate can maintain stable performance under specific environmental conditions.

- Environmental performance requirements: The copper clad laminate should comply with relevant environmental standards, contain no harmful substances, no odor, and have no adverse effects on the human body and the environment.

What are the pros and cons of copper cladding?

Advantages of copper clad laminate for circuit boards

- Excellent electrical conductivity: copper clad laminate for circuit boards can provide high electrical conductivity and can be used for high-speed signal transmission and high current transmission.

- Good corrosion resistance: The surface of copper clad laminate for circuit boards is coated with a protective copper oxide layer, which can effectively prevent copper from corrosion in humid and acidic environments and extend the life of the circuit board.

- Easy to process and print: After processing, copper clad laminate for circuit boards can be processed and printed by etching, gold plating, machining and other methods.

- Convenient for the production of multi-layer circuit boards: copper clad laminate for circuit boards can be used as inner copper foil for the production of multi-layer circuit boards, which can improve the performance and density of circuit boards and reduce the volume of circuit boards.

Disadvantages of copper clad laminate for circuit boards

- High cost: Compared with other materials such as aluminum substrates, copper clad laminate for circuit boards has a higher manufacturing cost, so the price is relatively expensive.

- Large thermal expansion coefficient: The thermal expansion coefficient of copper clad laminate for circuit boards is different from that of other materials, which can cause bending and cracking of circuit boards when different temperatures change.

- Corrosion performance needs to be improved: Although the copper clad laminate of the circuit board has good corrosion resistance, it may still be damaged by strong acid, strong alkali or high temperature, which needs further improvement.

What is copper clad laminate made of?

Copper clad laminates are mainly made of electronic fiberglass cloth or other reinforcing materials impregnated with resin, covered with copper foil on one or both sides and hot pressed. This material is referred to as copper clad laminate (Copper Clad Laminate, CCL), which is the substrate material of printed circuit boards (PCBs) and also the carrier of electronic components.

The manufacturing process of copper clad laminates includes impregnating electronic fiberglass cloth or other reinforcing materials with resin, then covering one or both sides with copper foil, and curing it into shape by hot pressing. Such a manufacturing process enables copper clad laminates to have excellent electrical and mechanical properties, which can meet the needs of different applications.

In addition, there are various types of copper clad laminates, including but not limited to high-frequency copper clad laminates, aluminum-based copper clad laminates, copper-based copper clad laminates, etc. These different types of copper clad laminates differ in material composition and application fields, but the common feature is that they are all based on copper foil and resin and are made through different processing techniques.

Copper Clad Laminate Grade?

FR-1 – phenolic cotton paper, this base material is commonly known as bakelite (more economical than FR-2)

FR-2 – phenolic cotton paper,

FR-3 – cotton paper, epoxy resin

FR-4 – Woven glass, epoxy resin

FR-5 – glass cloth, epoxy resin

FR-6 – matte glass, polyester

G-10 – glass cloth, epoxy resin

CEM-1 – cotton paper, epoxy resin (flame retardant)

CEM-2 – cotton paper, epoxy resin (non-flame retardant)

CEM-3 – glass cloth, epoxy resin

CEM-4 – glass cloth, epoxy resin

CEM-5 – glass cloth, polyester

AIN – aluminum nitride

SIC – silicon carbide

What is copper clad laminate used for?

- Electronic communication field

Copper clad laminates are widely used in electronic products such as mobile phones, computers, communication equipment, network equipment, etc. Among them, mobile phones are one of the most important application fields of copper clad laminates, and the quality of copper clad laminates used in mobile phones has a great impact on the performance and quality of mobile phones. - Computer field

With the development of computers, the application scope of copper clad laminates has gradually expanded, and gradually become an indispensable part of computer hardware. For example, copper clad laminates are widely used in hardware such as power boards, motherboards, expansion cards, and memory sticks. - Consumer electronics field

With the increasing popularity of consumer electronic products, the application of copper clad laminates in this field has gradually increased. For example, copper clad laminates are used in products such as smart watches and smart homes. - Automotive electronics field

Automotive electronics is one of the future development directions, and copper clad laminates are also widely used in the field of automotive electronics, such as in-vehicle entertainment systems, in-vehicle navigation systems, body control systems, etc.

All electronic machines, including aviation, aerospace, remote sensing, telemetry, remote control, communications, computers, industrial control, household appliances, and even advanced children’s toys, are all important electronic materials that are indispensable.