As a leading aluminum printed circuit boards manufacturer with over 18 years experience, we provide full turn-key service for all the world. In our aluminum base print circuit boards factories, we equipped with advanced high precision manufacturing and testing equipment to ensure the high quality and fast delivery.

What is Aluminum Printed Circuit Board

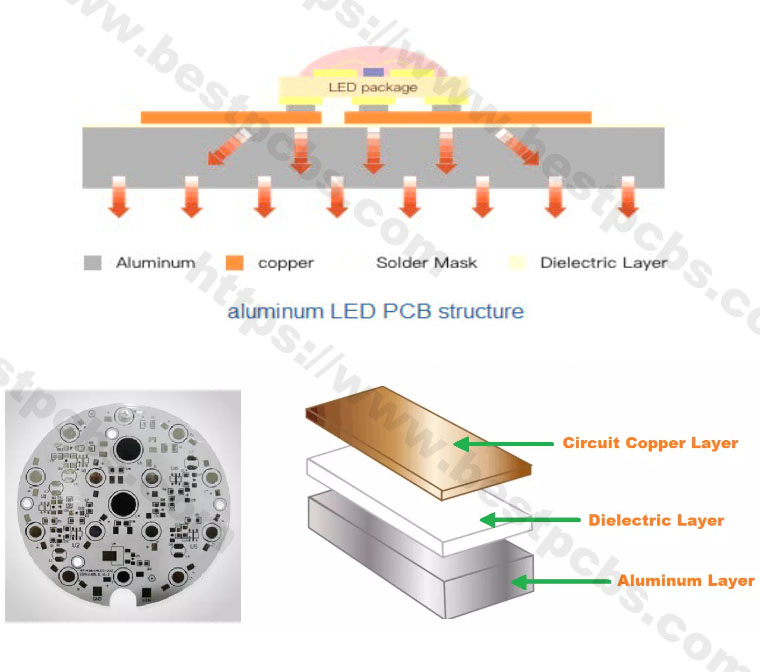

Aluminum printed circuit board is a metal-based copper-clad board with good heat dissipation function. Generally, a single-sided board consists of three layers, namely the circuit layer (copper foil), the insulation layer and the metal base layer. There are also designs for high-end use as double-sided boards, with the structure of circuit layer, insulation layer, aluminum base, insulation layer, and circuit layer. Very few applications are multi-layer boards, which can be made of ordinary multi-layer boards, insulation layers, and aluminum bases.

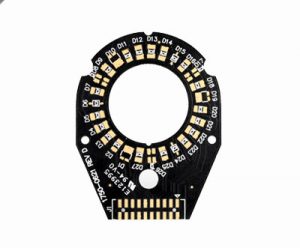

LED aluminum printed circuit boards are just circuit boards made of aluminum alloy. In the past, our general circuit boards were made of fiberglass, but because LEDs generate a lot of heat, the circuit boards used for LED lamps are generally aluminum printed circuit boards, which can conduct heat quickly. The circuit boards used for other equipment or electrical appliances are still fiberglass boards!

What are the advantages of aluminum PCB?

- Heat dissipation

Many double-sided boards and multi-layer boards have high density and high power, and it is difficult to dissipate heat. Conventional printed circuit board substrates such as FR4 and CEM3 are poor conductors of heat, with insulation between layers, and heat cannot be dissipated. If local heating of electronic equipment is not eliminated, electronic components will fail at high temperatures, and aluminum printed circuit boards can solve this heat dissipation problem. - Thermal expansion

Thermal expansion and contraction are the common nature of materials, and the thermal expansion coefficients of different materials are different. Aluminum-based printed circuit boards can effectively solve the heat dissipation problem, thereby alleviating the thermal expansion and contraction problems of different materials of components on the printed circuit board, and improving the durability and reliability of the whole machine and electronic equipment. In particular, it solves the thermal expansion and contraction problems of SMT (surface mount technology). - Dimensional stability

Aluminum-based printed circuit boards are obviously much more stable in size than printed circuit boards made of insulating materials. Aluminum-based printed circuit boards and aluminum sandwich panels, heated from 30℃ to 140~150℃, have a dimensional change of 2.5~3.0%. - Other advantages

Aluminum-based printed circuit boards have a shielding effect; high strength, replacing brittle ceramic substrates; ease of use, safe use of surface mounting technology; reducing the truly effective area of the printed circuit board; replacing components such as radiators, improving product heat resistance and physical properties; reducing production costs and labor.

How does an aluminum PCB work?

The working principle of aluminum printed circuit boards mainly relies on its unique three-layer structure: circuit layer (copper foil), insulation layer and metal base layer. This structure enables aluminum printed circuit boards to have good heat dissipation function.

Specifically, the power device is mounted on the circuit layer. When the device is running, the heat generated is quickly transferred to the metal base layer through the insulation layer, and then the metal base layer transfers the heat away, thereby achieving effective heat dissipation of the device. This design enables aluminum printed circuit boards to significantly reduce thermal resistance, provide excellent thermal conductivity, and maintain excellent mechanical properties.

Aluminum printed circuit boards also comply with RoHS requirements and are more suitable for SMT processes. In the circuit design scheme, heat diffusion is extremely effectively processed, the module operating temperature is reduced, the service life is extended, and the power density and reliability are improved. By reducing the configuration of heat sinks and other hardware, aluminum printed circuit boards can also reduce product size, reduce hardware and assembly costs, and optimize the combination of power circuits and control circuits.

Types of printed circuit board aluminum

The classification of aluminum printed circuit boards mainly includes flexible aluminum printed circuit boards, hybrid aluminum printed circuit boards, multi-layer aluminum printed circuit boards and through-hole aluminum printed circuit boards.

1. Flexible aluminum printed circuit boards

Utilize flexible dielectric materials to provide excellent electrical insulation, flexibility and thermal conductivity, suitable for a variety of shapes and angles, and eliminate the need for expensive fixtures, cables and connectors.

2. Hybrid aluminum printed circuit boards

In a “hybrid” IMS structure, “sub-assemblies” of non-thermal substances are processed independently and then bonded to an aluminum substrate using thermal materials. Common structures are 2-layer or 4-layer sub-assemblies made of FR-4, bonded to an aluminum substrate with thermal dielectrics, which helps dissipate heat, improve rigidity and act as a shield.

3. Multi-layer aluminum printed circuit boards

In the high-performance power supply market, it is made of multi-layer thermally conductive dielectrics, with one or more layers of circuits buried in the dielectric, and blind holes are used as thermal vias or signal paths to provide effective heat dissipation solutions for complex designs.

4. Through-hole aluminum printed circuit boards

Before lamination, the aluminum is plated and filled with dielectric, thermal materials or sub-components are laminated to both sides of the aluminum using thermal bonding materials, and plated through holes pass through the gaps in the aluminum to maintain electrical insulation.

Aluminum PCB Structure

- Circuit layer

The circuit layer (generally electrolytic copper foil) is etched to form a printed circuit for assembly and connection of devices. Compared with traditional FR-4, with the same thickness and line width, aluminum printed circuit boards can carry higher currents. - Insulation layer

The insulation layer is the core technology of aluminum printed circuit boards, which mainly plays the role of bonding, insulation and heat conduction. The insulation layer of aluminum printed circuit boards is the largest thermal barrier in the power module structure. The better the thermal conductivity of the insulation layer, the more conducive it is to the diffusion of heat generated by the device during operation, and the more conducive it is to reduce the operating temperature of the device, thereby achieving the purpose of increasing the power load of the module, reducing the volume, extending the life, and increasing the power output. - Metal base

The type of metal used for the insulated metal substrate depends on the comprehensive consideration of the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface state and cost of the metal substrate.

Aluminum Printed Circuit Board Process

Material: Aluminum printed circuit board is a heat dissipation material with excellent thermal conductivity. Aluminum alloy materials with high thermal conductivity, high strength and good corrosion resistance are usually selected. Choosing the right substrate material has a very important influence on the stability and heat dissipation performance of aluminum printed circuit boards.

Cutting: Cut the substrate into plates of appropriate size and into the shape of the entire circuit board. Cutting methods include laser cutting, mechanical cutting, etc. After cutting, it needs to be polished to meet the requirements of the next drilling.

Grinding: Grinding is to form a smooth surface on the substrate material and facilitate the next drilling operation. Factors affecting the grinding effect include the type and accuracy of the tool, the type and concentration of the grinding fluid, the pressure, etc.

Drilling: Drilling is to form wiring holes for components on the circuit board. Most of them are now using CNC drilling machines, which can make the drilling accuracy higher. Factors affecting the drilling quality include the material and geometric characteristics of the drill bit, the drilling speed, the drilling depth, and the drilling position accuracy.

Chemical treatment: Chemical treatment is an extremely important step in the manufacturing process of aluminum printed circuit boards. The appropriate circuit layer structure is prepared by etching, copper plating, surface treatment and other methods. This step requires strict control of parameters such as the concentration, temperature and time of the corrosive agent and electrolyte to obtain the required surface structure and quality.

Copper plating: Copper plating is to form a copper layer that connects the circuit and the ground wire, usually using methods such as chemical copper plating. Adverse factors of copper plating include uneven copper layer, excessive roughness, pinholes, and deformation of the copper layer.

Welding: Welding is a necessary step to directly solder electronic devices to aluminum printed circuit boards. Welding methods include manual welding and automated welding. During the welding process, the welding temperature, time and welding quality need to be strictly controlled to ensure reliable solder joints.

What is the thermal conductivity of aluminum PCB?

The thermal conductivity of aluminum printed circuit boards refers to the amount of heat transferred by a material per unit time and per unit area, usually expressed in W/m·K. The difference between 1.0, 1.5, and 2.0 thermal conductivity.

1.0 W/m·K: The insulation layer of the general-purpose aluminum-based copper-clad laminate is composed of an epoxy glass cloth bonding sheet, which is suitable for the heat dissipation needs of general electronic products.

1.5 W/m·K: The insulation layer of the high-heat dissipation aluminum-based copper-clad laminate is composed of a high-thermal-conductivity epoxy resin or other resin, which is suitable for occasions requiring higher heat dissipation performance.

2.0 W/m·K: The insulation layer of the aluminum-based copper-clad laminate for high-frequency circuits is composed of a polyolefin resin or polyimide resin glass cloth bonding sheet.

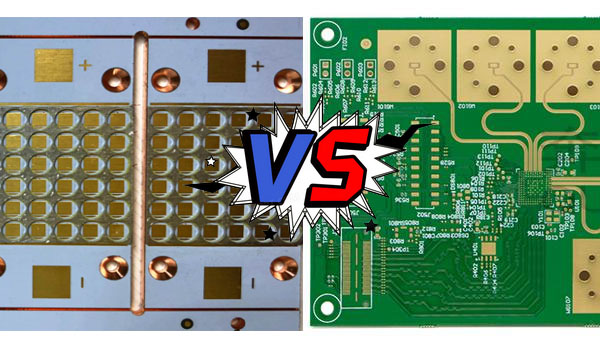

What is the difference between aluminum PCB and FR4?

The main differences between aluminum printed circuit boards and FR-4 circuit boards are materials, thermal conductivity, mechanical properties, cost, and application areas.

- Materials:

Aluminum printed circuit boards are mainly composed of aluminum alloys, and the surface is usually coated with an insulating layer with good thermal conductivity, such as aluminum oxide (Al2O3).

The substrate of FR-4 circuit boards is a glass fiber reinforced epoxy resin, which is formed by impregnating glass fiber cloth with epoxy resin to form a composite material.

- Thermal conductivity:

Aluminum printed circuit boards have good thermal conductivity and are suitable for applications with high heat dissipation requirements, such as LED lighting and electronic power supplies.

FR-4 circuit boards have relatively poor thermal conductivity and are usually used in general electronic devices, not suitable for scenarios with high heat dissipation requirements. - Mechanical properties:

Aluminum printed circuit boards are relatively hard and have good mechanical properties, and are suitable for applications that require a certain mechanical strength.

FR-4 circuit boards are relatively soft and easy to process, but may not be as good as aluminum printed circuit boards in terms of mechanical strength. - Cost:

Due to the high manufacturing process and material costs of aluminum printed circuit boards, the cost of aluminum printed circuit boards is relatively high.

FR-4 circuit boards have relatively low manufacturing processes and material costs, and are usually an affordable choice. - Application areas:

Aluminum printed circuit boards are mainly used in applications that require good heat dissipation performance, such as LED lamps, power modules, automotive electronics, etc.

FR-4 circuit boards are suitable for general electronic products, such as computer hardware, communication equipment, consumer electronics, etc.

What are aluminum PCBs used for?

- Audio equipment: input and output amplifiers, balanced amplifiers, audio amplifiers, preamplifiers, power amplifiers, etc.

- Power supply equipment: voltage stabilizers, regulators, DC-AC adapters, etc.

- Communication electronic equipment: high-frequency amplifiers, filter appliances, and transmission circuits.

- Office automation equipment: motor drivers, etc.

- Computers: power supply devices, floppy disk drives, motherboards, etc.

- Power modules: inverters, solid-state relays, rectifier bridges, etc.

- Electronic control: relays, transistor bases, and cooling of components in various circuits;

- Switches, microwaves: radiators, semiconductor device insulation heat conduction, motor controllers;

- Industrial vehicles: igniters, voltage regulators, automatic safety control systems, and lighting conversion systems;

- LED displays (two modes: LED display; display using LED light sources)

- Lamps and lighting: With the promotion of energy-saving lamps, various energy-saving and gorgeous LED lamps are very popular in the market, and aluminum printed circuit boards used in LED lamps have also begun to be used on a large scale.

Aluminum printed circuit boards supplier

As a leading aluminum printed circuit boards manufacturer with over 18 years experience, we provide full turn-key service for all the world. In our aluminum base print circuit boards factories, we equipped with advanced high precision manufacturing and testing equipment to ensure the high quality and fast delivery

Best Technology specializes in providing prototyping service of customized aluminum PCB solutions to meet the diverse needs of our clients. To make sure the one-time success of pcb prototyping, we proceed SI, PI, EMC, DFM analysis during the production. We are committed to be the most reliable aluminum printed circuit boards supplier in the world!