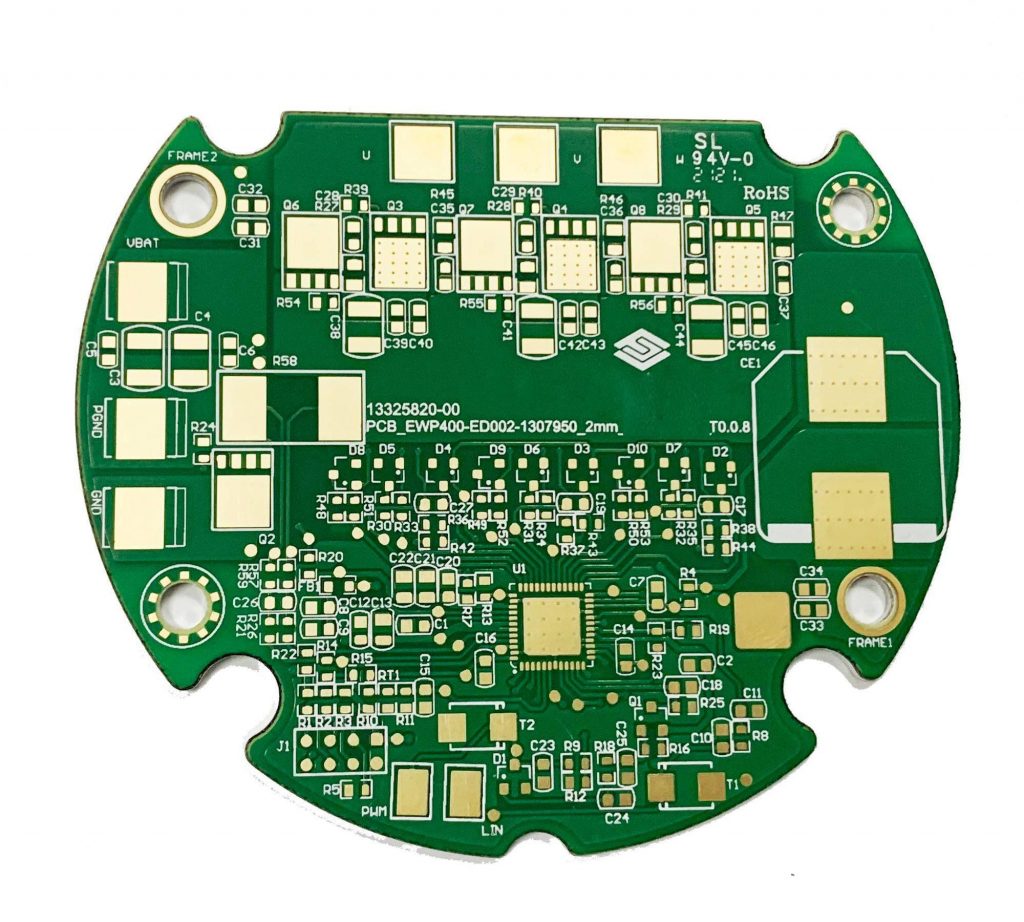

In the field of electronic manufacturing, PCB (Printed Circuit Board) is an indispensable basic component. For electronic equipment manufacturers, it is very important to accurately calculate the cost of PCB circuit boards.

In the PCB processing plant, the cost estimation method of PCB is composed of many factors. Most of the cost comes from the number of layers, materials, drilling volume, and surface treatment process of the board. Generally speaking, the board cost is about half of the total cost.

What is the average cost of a PCB?

The average cost of PCB varies due to many factors, and there is no fixed value.

The cost of PCB is mainly composed of the following parts:

1. Substrate cost: Substrate is the basic component of PCB. Common material types include FR4, CEM-1, aluminum substrate, etc. The price of different types of substrates varies greatly.

2. Process cost: The manufacturing process of PCB includes inner layer circuit production, lamination, drilling, electroplating, outer layer circuit production, solder mask treatment, text printing and surface treatment. Each step requires professional equipment and technicians to operate, so there will be corresponding costs.

3. Inspection cost: After the PCB is manufactured, a series of tests are required to ensure its quality, including electrical performance testing, reliability testing, and appearance inspection.

4. Other additional expenses: In addition to the above main costs, there are some additional expenses to consider, such as special design or modification services may require additional design fees. In addition, additional costs such as packaging, transportation, and taxes also need to be taken into consideration.

In summary, the cost of PCB is composed of multiple aspects, including substrate cost, process cost, inspection cost, and other additional expenses, which need to be comprehensively evaluated based on specific board type, number of layers, drilling amount, surface treatment process, and other factors.

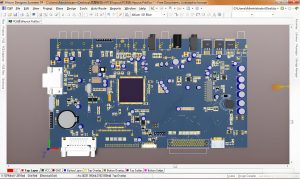

How to calculate PCB design cost?

Material cost is an important part of design cost, including board, solder mask ink, chemical agents, etc. These costs are relatively easy to calculate, but the additional losses caused by material loss and risks during storage and use need to be considered.

Process cost covers equipment use time, worker wages, energy consumption, etc. When calculating the cost of equipment use, the frequency and duration of equipment use and the total investment cost should be taken into account.

Equipment depreciation and maintenance costs are also a part that cannot be ignored, including the original price of the equipment, accumulated depreciation, and maintenance and repair costs.

Other related costs such as administrative costs, quality control costs, and R&D costs, although more difficult to calculate, have a significant impact on the total cost of the project.

Material costs include substrate materials, circuit board materials, and copper foil, processing costs involve drilling, copper plating, graphic etching and other processes, and labor costs include direct and indirect labor costs. Through these calculations, plus a reasonable profit margin, the final PCB quotation is obtained.

What is the most expensive PCB?

The most expensive PCB may be an electroless nickel electroless palladium immersion gold (ENEPIG) PCB.

This electroplating material has a copper-nickel-palladium-gold layer structure that can be directly bonded to the electroplating layer through wires. The last layer of gold is very thin, just like electroless nickel immersion gold (ENIG).

The gold layer is soft, so excessive mechanical damage or deep scratches may expose the palladium layer. Although the gold layer is soft, ENEPIG’s PCB is often considered the first choice in high-end applications due to its high-quality electrical performance and durability, so its cost is relatively high.

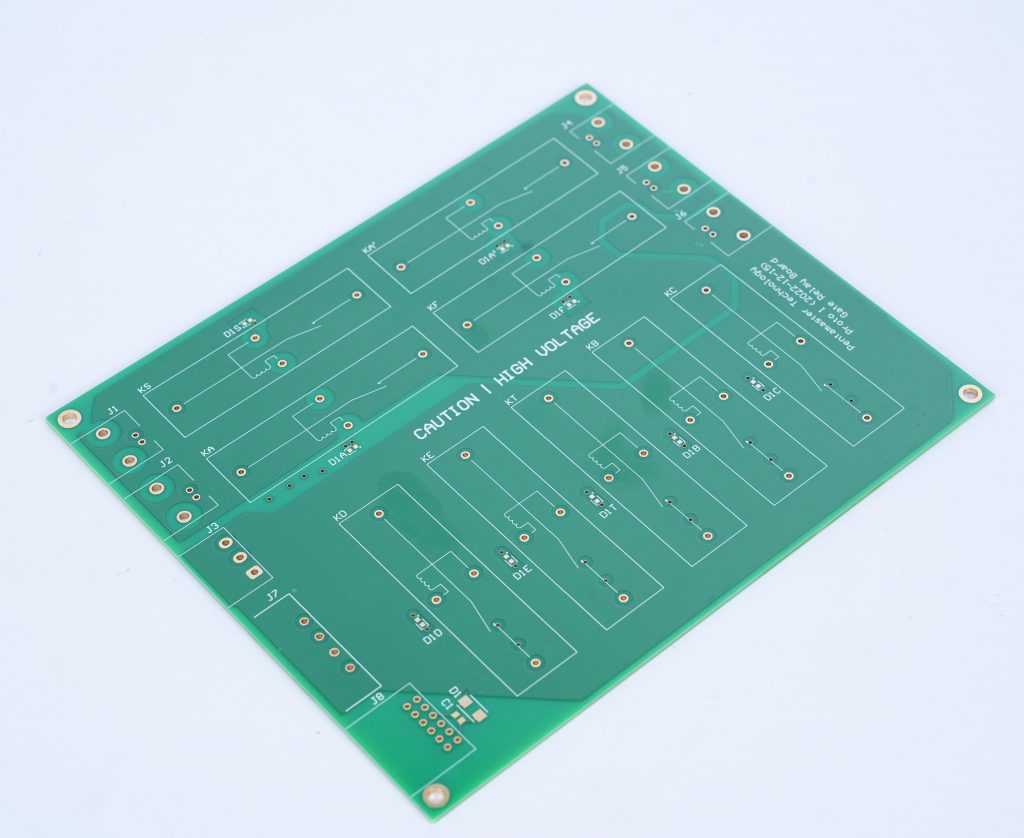

In addition, the production of high-end precision PCB circuit boards is also expensive, including multi-layer boards, boards with BGA, HDI circuit boards, etc. These products usually require more complex production processes and higher material quality, so the cost is also relatively high.

How much does PCB assembly cost per component?

The PCB assembly cost of each component is composed of multiple factors, including board costs, processing costs, testing costs, and other additional costs.

Board costs are an important part of PCB assembly costs. The types of boards, such as FR4, CEM-1, aluminum substrates, etc., have large price differences.

FR4 boards are widely used due to their excellent electrical and processing properties, but their prices are affected by fluctuations in the prices of raw materials such as international copper prices, epoxy resins, and glass fiber cloth.

Aluminum substrates are favored in certain specific applications due to their good heat dissipation performance, but their prices are usually much higher than FR4 boards.

Processing costs cover multiple links in the PCB manufacturing process, such as inner layer circuit production, lamination, drilling, electroplating, outer layer circuit production, solder mask, text printing and surface treatment.

Each link requires professional equipment and technicians to operate, so there will be corresponding costs. In particular, the costs of steps such as drilling and electroplating will vary according to factors such as the number of holes, the area and thickness of the electroplating.

Testing costs are an important link to ensure the quality of PCBs. After the production is completed, the PCB needs to undergo a series of tests, including electrical testing, reliability testing, and appearance inspection.

These tests require not only professional testing equipment, but also experienced testers to operate and analyze the results, so certain costs will also be incurred.

Other additional costs include additional design fees that PCB manufacturers may charge if customers require special design or modification services. In addition, there are some additional costs such as packaging, transportation and taxes that need to be taken into account.

In summary, the PCB assembly cost of each component is determined by the board cost, processing cost, testing cost and other additional costs, and the specific cost will vary according to the specific needs of the project and the manufacturer’s quotation.

What is the cheapest PCB finish?

The cheapest PCB surface treatment process is hot air solder leveling (HASL).

HASL is a commonly used PCB surface treatment process, which is divided into lead-containing tin and lead-free tin. It is one of the most commonly used and relatively inexpensive surface treatment processes.

This process is to immerse the circuit board in molten solder (tin/lead), and then the solder covers all exposed copper surfaces on the board to form a HASL surface finish.

HASL is not only one of the cheapest types of PCB surface treatment, but its process temperature is 250℃, the shelf life can reach 12 months, and the surface treatment thickness ranges from 1-40um, making it an economical and practical choice.

In addition, HASL is divided into leaded and lead-free. Although the leaded version is gradually replaced by the lead-free version for environmental reasons, the lead-free HASL still maintains a low cost, making it the preferred choice for projects with limited budgets.

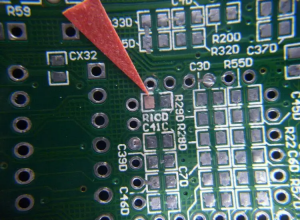

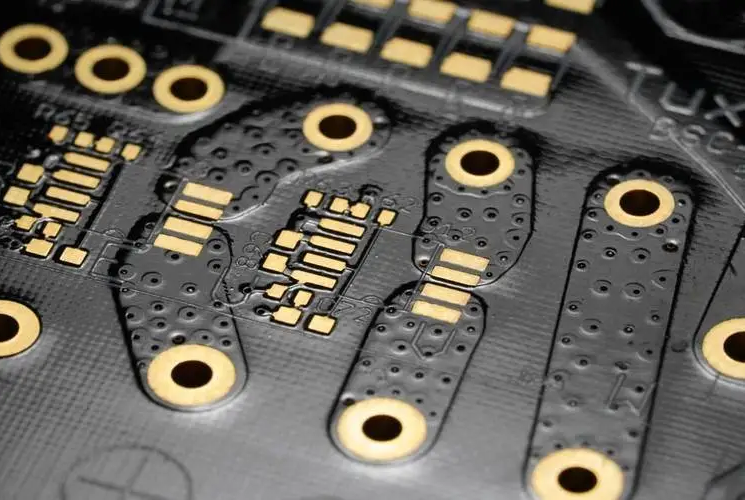

Do vias make PCBs more expensive?

Vias may indeed increase the cost of PCBs.

Vias are an important part of multi-layer PCB boards, and they play a key role in the design and manufacturing process of circuit boards. Vias can be divided into buried vias, blind vias and through holes. Among them, through holes pass through the entire circuit board and are used to achieve internal interconnection or component installation and positioning. They are the most commonly used types.

The number and type of vias directly affect the cost of the PCB, because each via needs to go through processes such as drilling and electroplating, which account for a considerable part of the cost of PCB board manufacturing.

Factors that affect the cost of PCBs also include the size of the vias. The smaller the via, the greater the manufacturing difficulty, and the corresponding increase in cost.

In addition, different types of vias require different processing technologies and materials, which also affects the cost. For example, the processing processes and difficulties of blind and buried vias are different, resulting in different prices.

The price difference between blind and buried vias is mainly caused by many factors such as material cost, complexity of processing process and difficulty of processing. Blind vias require double-sided or multi-layer composite boards, which have higher material costs, while buried vias can be processed using single-sided boards, which have relatively low costs.

In addition, the processing processes of blind vias are diverse, the process is complex, and higher technology and cost are required. The processing time is long and the manufacturing cost is relatively high.

In summary, the number, type, size and processing method of vias will affect the cost of PCB. When designing PCB, it is necessary to find a balance between function and cost to optimize the design and cost control.

Conclusion:

The unit cost of PCB is affected by many factors, including but not limited to the number of layers, material, drilling amount, and surface treatment process of the board. BEST Technology has many years of experience in PCB board design and has skilled experience in handling various factors that affect PCB cost. It can help you find the best way to solve all your concerns about PCB cost.

Tags: PCB, pcb cost, pcb design, PCBA