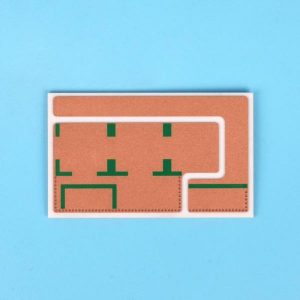

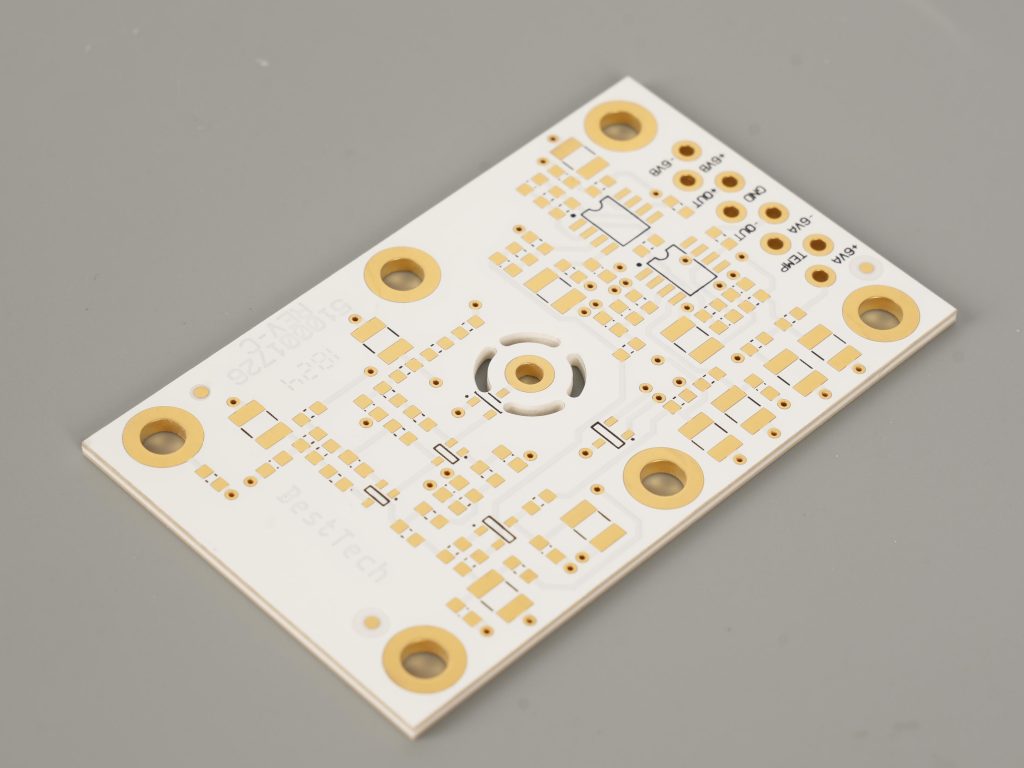

Ceramics have emerged in many fields with their unique properties, and the thermal conductivity of ceramics has become one of the focuses of attention. Ceramic PCBs have the advantages of high thermal conductivity, good insulation performance, high mechanical strength and high precision, and have been widely used in high-power LED lighting, automotive electronics, and aerospace.

Is ceramic a good thermal conductor?

Ceramic PCB is a good thermal conductor. â

The thermal conductivity of ceramic PCBs is due to the materials used, such as aluminum oxide (Al2O3) and aluminum nitride (AlN). These materials have high thermal conductivity and can effectively dissipate heat, prevent overheating, and ensure that electronic components can still work stably in high temperature environments.

The thermal conductivity of aluminum nitride reaches 170W/(mK)~220W/(mK). Such high thermal conductivity enables ceramic PCBs to effectively dissipate heat when the chip is working, ensuring that the sensor signal will not be distorted, especially in high temperature, high vibration, and corrosion environments. The signal of ceramic PCBs is still efficient, sensitive, and accurate. â

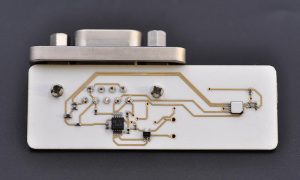

In addition, the manufacturing process of ceramic PCB adopts LAM technology, which is a laser rapid activation metallization technology, making ceramic PCB highly versatile and can replace the entire traditional printed circuit board with a simpler structure and enhanced performance.

In summary, ceramic PCB not only has good thermal conductivity, but also can maintain stability and reliability in harsh environments such as high temperature, high vibration, corrosion, etc., which is an ideal choice for high-performance electronic components.

What are the thermal properties of ceramics?

The thermal performance of ceramic PCB is significantly better than that of traditional printed circuit boards (PCBs).

The thermal performance of ceramic PCB is mainly reflected in the following aspects:

- High thermal conductivity: The thermal conductivity of ceramic PCB is usually above 18W/mK, which is much higher than that of traditional ceramic materials and organic substrates. It can effectively transfer heat from the heating element to the heat sink and improve the heat dissipation efficiency.

- Good insulation performance: The ceramic substrate has good insulation performance and can withstand high voltage and high current, ensuring the safety and stability of the circuit.

- High mechanical strength: The ceramic substrate has high mechanical strength, can withstand large pressure and impact, and is not easy to break and deform.

- âGood chemical stabilityâ: Ceramic substrates have good chemical stability and can withstand corrosion from chemicals such as acids, alkalis, and salts, and are not prone to aging and deteriorationâ.

- âThin and lightweightâ: High thermal conductivity ceramic substrates can be made into thin and lightweight products to meet the needs of miniaturization and lightweight electronic devicesâ.

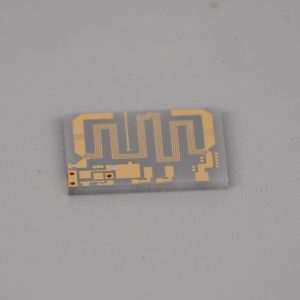

These characteristics make ceramic PCBs the first choice for applications that generate a lot of heat and require efficient thermal management, especially in radio frequency (RF) and microwave applications, which can maintain signal integrity and minimize signal loss, making them indispensable in industries such as telecommunications, aerospace, and satellite communicationsâ.

In addition, ceramic PCBs’ chemical resistance and ability to withstand harsh environments make them ideal for applications that require contact with corrosive substancesâ.

What material has the highest thermal conductivity?

Aluminum nitride (AlN) has the highest thermal conductivity. â

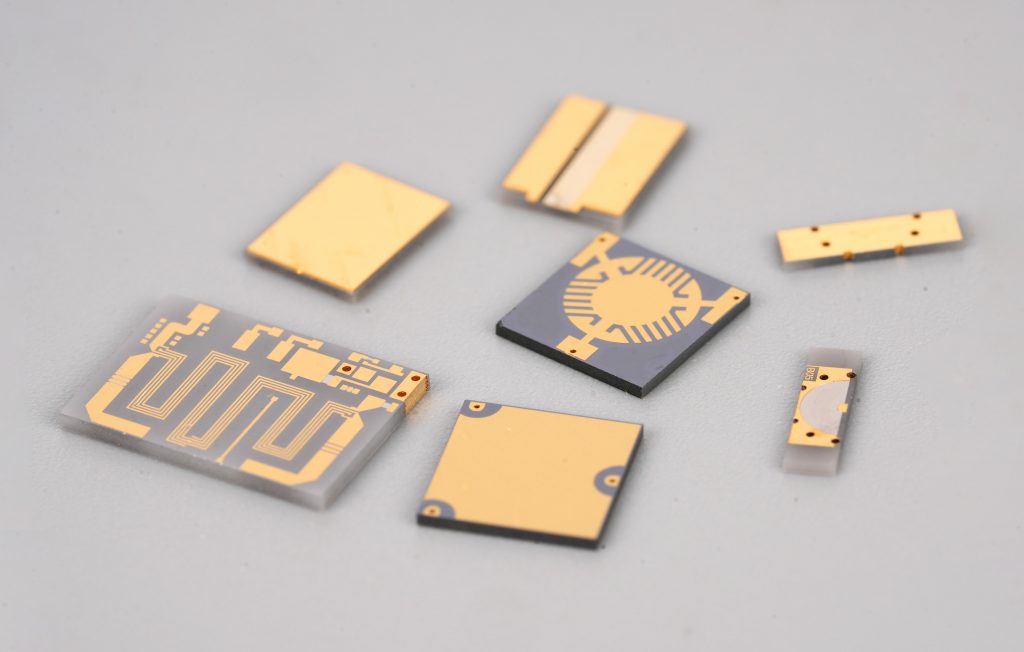

Aluminum nitride (AlN) is an excellent ceramic material with extremely high thermal conductivity and low expansion coefficient. Its thermal conductivity is as high as 170-230 W/mK, making it one of the ceramic substrate materials with the best thermal conductivity.

The effective heat dissipation performance of aluminum nitride makes it particularly suitable for the heat dissipation needs of high-power density electronic devices and high-frequency electronic devices. In addition, aluminum nitride also has the characteristics of high hardness, high mechanical strength, strong corrosion resistance, high biocompatibility, and a thermal expansion coefficient close to silicon, so it performs well in applications such as high-power LEDs, power modules, and laser fields.

In contrast, other common ceramic PCB materials such as aluminum oxide (Al2O3) have low thermal conductivity, generally between 18-35 W/mK. Although they have good insulation properties and mechanical strength, their thermal conductivity is not as good as aluminum nitride and cannot meet the heat dissipation needs of high-power devices. Therefore, aluminum nitride is the preferred material in applications that require efficient heat dissipation.

What is the thermal conductivity of ceramic in W mK?

Ceramic PCB, as a high thermal conductivity material, its thermal conductivity depends on the type of ceramic substrate used. The thermal conductivity of âalumina ceramicâ is between 18-35 W/mK, while the thermal conductivity of âaluminum nitride ceramicâ is as high as 170-230 W/mK, which shows that aluminum nitride ceramic has higher thermal conductivity than alumina ceramic.

In addition, the thermal conductivity of ceramic PCB is better than that of traditional âFR4 PCBâ or âmetal substrateâ, the latter of which usually has a thermal conductivity of less than 3W/mK. Especially in the field of products that require high heat dissipation performance, ceramic PCB is favored for its excellent thermal conductivity.

Do ceramics have good conductivity?

The conductivity of ceramic PCB (printed circuit board) is due to the ceramic substrate it uses. This substrate material has good thermal and electrical conductivity and can withstand high power density.

Ceramic substrates are usually made of materials such as alumina, aluminum oxide and silicon nitride, which give ceramic substrates excellent electrical properties and mechanical strength, making them widely used in high-frequency communications.

The thermal conductivity of ceramic PCB is between 25~230w, with very good insulation and thermal conductivity. At the same time, its dielectric constant is low, dielectric loss is small, and it has excellent high-frequency performance. These characteristics make ceramic PCB perform well in applications that require efficient thermal management and maintain signal integrity.

How good of an insulator is ceramic?

Ceramic PCB has excellent insulation performance. â

The insulation performance of ceramic PCB is due to its material characteristics. It is based on ceramic materials and has extremely high hardness and wear resistance. It also has good insulation performance and thermal stability. Ceramic materials themselves have excellent electrical insulation properties and can effectively prevent short circuits and current leakage.

Does ceramic have electrical resistance?

âCeramic PCB has resistance. â

Ceramic PCB, as a high-performance electronic substrate material, has excellent physical and electrical properties. In ceramic PCB, resistors are part of electronic components, used to limit current and reduce voltage, and are an indispensable component in the circuit. The resistors of ceramic PCBs are usually installed on the circuit board together with other electronic components to complete the function of the circuit together.

The thermal conductivity of ceramic is one of its important properties. Different types of ceramic materials have different thermal conductivities. In the future, with the continuous development and progress of electronic devices, the performance requirements for PCBs will become higher and higher, and ceramic PCBs will continue to develop and innovate to meet market demand.

Tags: ceramic, ceramic PCB, PCB, PCBA