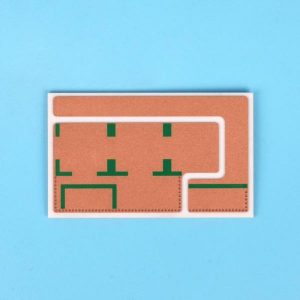

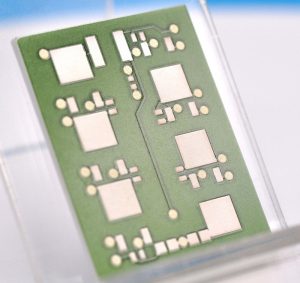

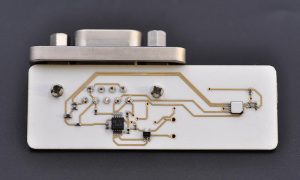

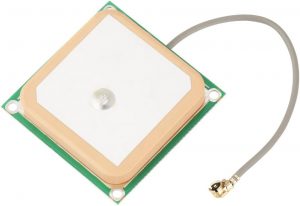

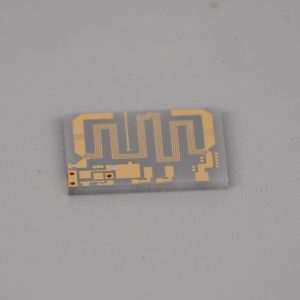

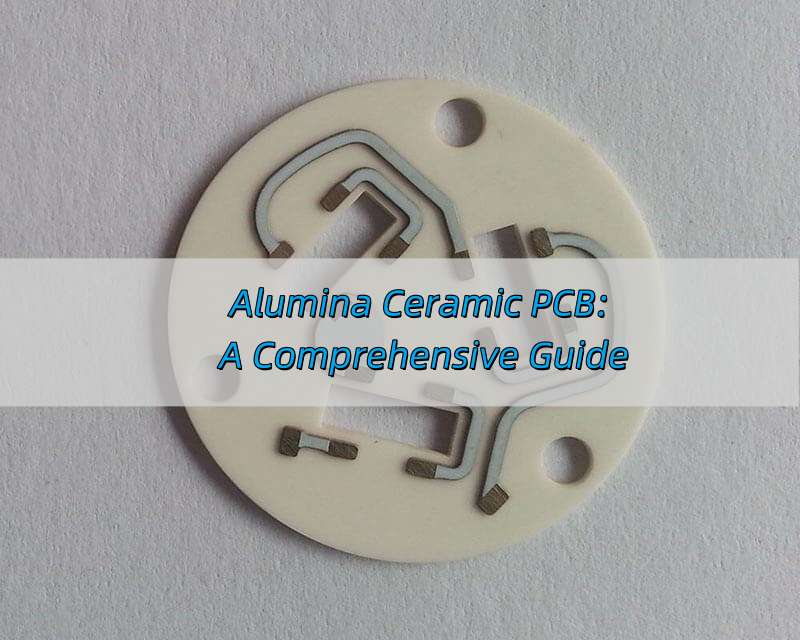

Alumina ceramic PCB (Printed Circuit Board) have gained significant attention in industries that demand high performance, such as electronics, medical devices, and automotive systems. Known for their excellent electrical insulation, thermal conductivity, and mechanical strength, alumina ceramics are widely used in applications that require precision and reliability. In this article, we will explore various aspects of alumina ceramics, focusing on their properties, uses, and potential benefits and drawbacks, especially in the context of PCB manufacturing.

What is Alumina Ceramic?

Alumina ceramics are produced by heating aluminum powder in a controlled environment to form a ceramic compound. The material is then used in various applications, such as semiconductors, sensors, and high-performance PCBs.

One of the reasons alumina ceramics is so popular in the electronics industry is its ability to function in harsh environments. It can withstand high temperatures and pressure without degrading, making it perfect for critical applications that require both durability and efficiency.

Can Alumina Ceramic be Machined?

Yes, alumina ceramic can be machined, but it requires specialized tools and techniques. While alumina is a hard material, it is brittle, which means it can crack or shatter if not handled carefully. Precision machining methods like laser cutting, diamond grinding, and CNC milling are commonly used to shape alumina ceramic substrates for PCBs.

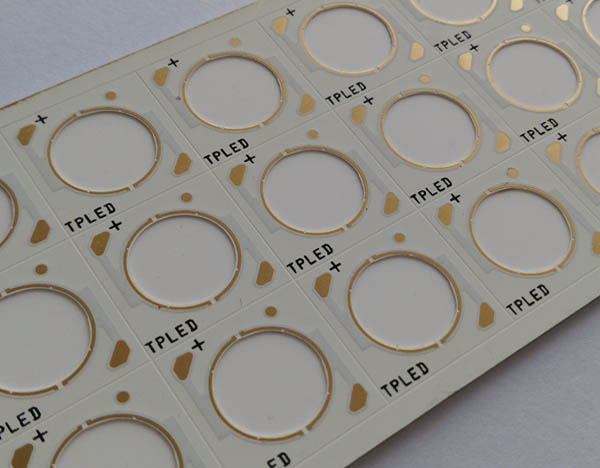

Manufacturers can produce alumina ceramic PCBs with fine features, such as microvias or intricate patterns, by using these advanced machining techniques. However, the machining process can be slow and expensive due to the material’s hardness. Despite these challenges, the benefits of alumina ceramics, like their excellent insulation and heat resistance, often outweigh the machining difficulties. At Best Technology, we pride ourselves on delivering multiple types of alumina ceramic PCB products that meet your high-quality standards while maintaining fast delivery times.

What is the Temperature Rating of Alumina Ceramic?

Alumina ceramic has a high-temperature resistance, making it ideal for environments that experience heat stress. Depending on the purity and grade of alumina, its temperature rating can vary, but most alumina ceramics can withstand temperatures ranging from 1600°C to 1900°C. This makes it suitable for applications in power electronics, automotive sensors, and even space exploration.

For PCB applications, the high thermal conductivity of alumina ensures that heat generated by electronic components is efficiently dissipated, preventing damage to sensitive circuits. This property is particularly valuable in power electronics, where overheating can lead to system failures.

Is Alumina Ceramic Magnetic?

No, alumina ceramic is not magnetic. It is a non-metallic material, meaning it does not exhibit magnetic properties. This characteristic makes alumina ceramics ideal for use in electronic components that require isolation from magnetic fields. For instance, in medical devices like MRI machines, non-magnetic ceramics like alumina help avoid interference with the equipment’s functioning.

The absence of magnetic properties in alumina ceramics makes it a preferred material for PCBs used in sensitive electronic applications where magnetic interference could disrupt performance.

Is Alumina Ceramic Safe?

Yes, alumina ceramic is safe to use in a wide range of applications. As a non-toxic and stable material, it poses no significant health risks when handled properly. In fact, it is often used in medical devices, including implants and prosthetics, due to its biocompatibility.

However, like any material, alumina ceramics should be handled with care during manufacturing. Dust or particles generated from machining can be hazardous if inhaled, so it’s important to follow proper safety protocols, such as wearing protective gear and working in well-ventilated areas. Overall, alumina is a safe and reliable material in many high-performance applications.

How Strong is Alumina Ceramic?

Alumina ceramic is known for its impressive mechanical strength. It ranks among the hardest materials available, which is second only to diamond. Alumina’s compressive strength is particularly remarkable, making it highly resistant to wear, abrasion, and pressure. This makes it ideal for applications that require robust components, such as PCB substrates in electronic devices.

The material’s strength also contributes to its durability in extreme environments. For example, in high-frequency communication circuits or power electronic systems, alumina ceramics maintain their structural integrity despite thermal and mechanical stresses.

What is the Advantage of Using Alumina as a Biomaterial?

Alumina has several advantages when used as a biomaterial. Its biocompatibility makes it suitable for medical implants, such as hip replacements and dental implants. The material does not cause allergic reactions or adverse immune responses, which is crucial when used in long-term implants within the human body.

Moreover, alumina’s resistance to wear and corrosion means that it can withstand the mechanical stresses and chemical environments found in the human body. As a result, it has become a popular choice for medical devices and prosthetics. Additionally, alumina ceramics are used in various healthcare technologies like surgical tools and diagnostic devices, benefiting from their precision, durability, and sterilization capabilities.

What are the Disadvantages of Alumina Ceramic?

While alumina ceramics offer many benefits, they do have some disadvantages. One of the main drawbacks is their brittleness. Although alumina is hard, it is also prone to cracking or breaking under sudden stress or impact. This is why it is important to handle alumina ceramics carefully during manufacturing and in application.

Additionally, alumina ceramic processing can be costly. Machining this material requires specialized equipment and skills, which can make it more expensive than other materials, particularly for custom or small-batch productions. Despite these challenges, the benefits of alumina ceramics often outweigh the negatives, particularly in applications that require high performance and reliability.

In brief, alumina ceramic PCBs offer a combination of high thermal conductivity, electrical insulation, and mechanical strength, making them an excellent choice for demanding applications. Whether in high-power electronics, medical devices, or aerospace systems, alumina ceramics provide the reliability and performance needed for modern technologies.

By understanding the properties, uses, and potential drawbacks of alumina ceramic, businesses can make informed decisions about using this material in their products. Despite the machining challenges and brittleness, the advantages of alumina—such as its heat resistance, safety, and mechanical strength—make it a preferred choice in various industries.

Choosing the right material for PCB manufacturing can be complex, but alumina ceramic continues to be a top contender for those seeking durable, high-performance substrates. If you are looking for reliable PCB solutions, alumina ceramic offers the performance you need to ensure your devices operate efficiently and effectively. As a qualified alumina ceramic pcb manufacturer, Best Technology is striving to provide multiple types of PCB products without MOQ requirement for our customers. Just feel free to reach out to us via sales@bestpcbs.com to get the personalized service.

Tags: Alumina Ceramic PCB, ceramic PCB, PCB