What is pcb finish nickel or électrolytique with champagne effect? PCB nickel plating is a process of depositing a nickel metal layer on the surface of a printed circuit board. Its core purpose is to enhance the performance and durability of the circuit board. Champagne effect electroplating is achieved by mixing the composition of the electroplating solution and precisely controlling the electroplating process parameters. It gives the circuit board a unique and elegant appearance.

What is pcb nickel champagne effect?

PCB nickel champagne effect refers to a champagne-like appearance and corresponding performance characteristics obtained by a specific nickel plating process on a printed circuit board (PCB).

- Color: It presents a light golden or light amber color similar to champagne. This unique color makes it stand out among many PCB surface treatment effects and has high recognition and decorativeness.

- Glossiness: It has a soft gloss, which is neither too bright mirror effect nor completely matte without gloss, but a moderate gloss between the two, giving people an elegant and textured visual experience.

Why choose champagne effect for pcb finishes?

There are several reasons for choosing champagne effect as PCB finish:

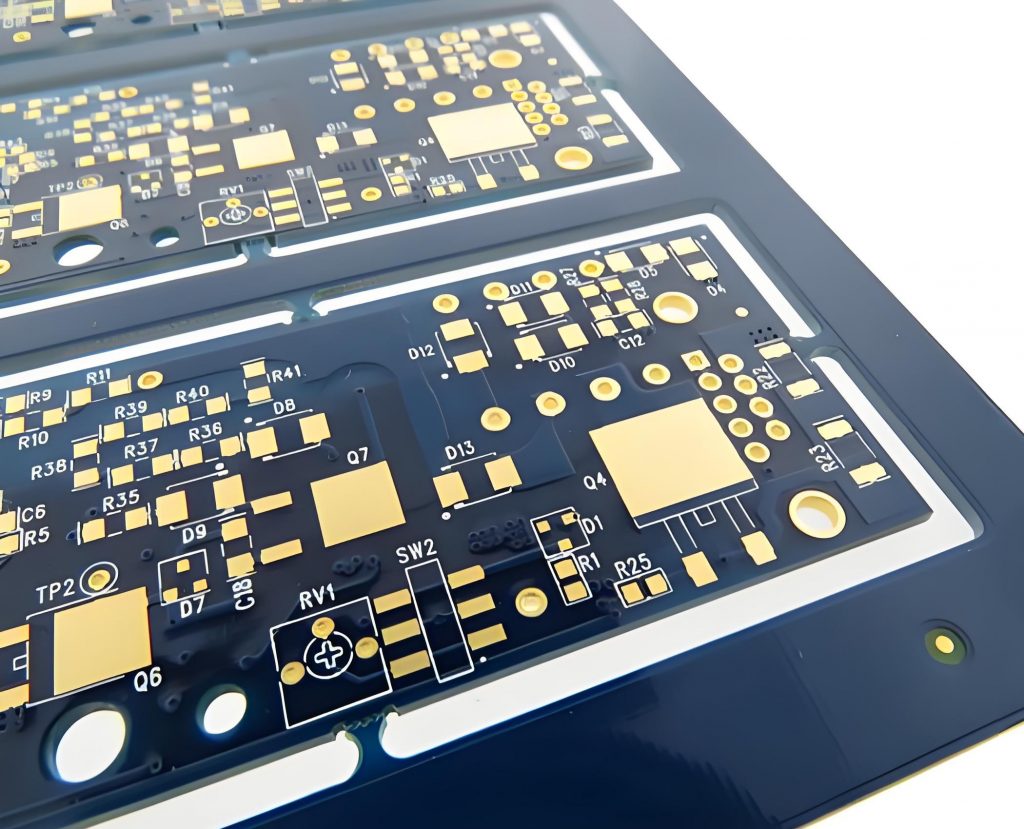

- Aesthetic advantage: Champagne color is elegant and noble, with unique color and soft gloss, which makes it stand out visually, and can meet the differentiated and exquisite needs of high-end electronic products for appearance design. It is suitable for equipment that is sensitive to light reflection, avoids reflection interference, and enhances the overall visual effect.

- Corrosion resistance: The champagne effect layer formed by nickel plating can effectively protect the copper foil from oxidation and corrosion. Whether it is in a harsh environment such as humidity, chemical exposure or outdoor, it can ensure the stability of PCB electrical performance and extend the service life.

- Electrical performance: The surface of the nickel layer is flat and smooth, which can reduce contact resistance and ensure the integrity and accuracy of high-frequency and high-speed signal transmission; good solderability helps to improve welding efficiency and quality and ensure stable electrical connection.

- Mechanical properties: With a certain hardness and wear resistance, it can withstand mechanical wear during production, assembly, transportation and use, such as PCBs with frequent plug-in and unplug interfaces, which can protect the circuits and plating and maintain the integrity and functionality of the PCB.

- Market demand: Meet consumers’ pursuit of personalized electronic products and help products stand out from the competition; fit the high-quality and high-end image of high-end products and enhance the market competitiveness of products.

Why nickel champagne finish is gaining popularity?

The increasing popularity of nickel champagne finish is mainly due to its advantages in both beauty and performance, and the production process is also improving.

From the aesthetic point of view, it meets the needs of personalized and high-end appearance of consumer electronic products. Its unique champagne color is exquisite and elegant, which can enhance product recognition and high-end image.

In terms of performance, good corrosion resistance can ensure the reliability of PCB in complex environments; excellent electrical performance adapts to high-end technical requirements such as high-frequency and high-speed signal transmission, and mechanical performance can also cope with various mechanical forces in practical applications.

At the same time, the mature production process reduces costs, and has strong compatibility with existing PCB manufacturing processes, which is convenient for promotion and application.

How does nickel champagne effect improve pcb quality?

Nickel champagne effect improves PCB quality in three aspects:

- Protective performance: First, it enhances corrosion resistance. The nickel layer can prevent the copper foil from being corroded by humid environment and chemicals, and prolong the service life of PCB. Second, it improves wear resistance. Its certain hardness can withstand mechanical friction and protect the circuit and plating.

- Electrical performance: Reduce contact resistance, and the flat and smooth surface reduces signal transmission loss and reflection. At the same time, it improves solderability, combines well with solder, improves welding quality and efficiency, and ensures reliable electrical connection.

- Appearance quality: The unique light golden or light amber color and soft luster enhance the recognition and beauty of PCB and increase the added value of high-end electronic products.

What impact does champagne effect have on pcb durability?

The champagne effect (usually achieved through nickel plating) has many positive effects on the durability of PCB:

1. Corrosion resistance

- Isolation protection: The copper foil of PCB is susceptible to oxidation and corrosion. The champagne effect nickel layer is like a solid shield, isolating the copper foil from corrosive substances in the outside world, thereby greatly reducing the possibility of corrosion of the copper foil.

- Long-term stability: This anti-corrosion property can ensure the stability of the electrical performance of the PCB during the long-term use of electronic products. The corrosion resistance brought by the champagne effect can significantly extend the service life of the PCB and reduce the failure and maintenance costs caused by corrosion.

2. Wear resistance

- Mechanical protection: During the production, assembly, transportation and daily use of PCBs, there will be various possible mechanical frictions. The champagne effect nickel layer has a certain hardness and can withstand these frictions and scratches, protecting the lines and plating on the surface of the PCB from damage.

- Maintain integrity: For frequently used electronic products, this wear resistance can ensure the integrity of the PCB, help avoid repeated friction and breakage, resulting in interruption of electrical connections, thereby improving the durability of the PCB.

Is champagne effect the best choice for premium pcbs?

Champagne effect is a good choice for premium PCBs, but not the absolute best choice.

From the advantages, it has appearance advantages, and the color and gloss make the PCB more refined and high-end. In terms of performance, it has good corrosion resistance and can stabilize electrical performance; the flat and smooth surface can reduce contact resistance, ensure signal quality, and has good solderability; in terms of mechanical properties, hardness and wear resistance can protect the circuit and plating.

However, it also has limitations. In terms of application scenarios, it may not be the most suitable when there are special requirements for extreme environments or electromagnetic shielding, and other targeted surface treatments are required.

PCB nickel plating can enhance the circuit board’s corrosion resistance, welding and multi-layer board connection performance, making it more durable and stable. Champagne effect electroplating adds aesthetic elements on the basis of the practicality of nickel plating, making it continuously advanced in performance and appearance, making the appearance of high-end electronic product circuit boards more refined.

Tags: pcb finish nickel or électrolytique with champagne effect