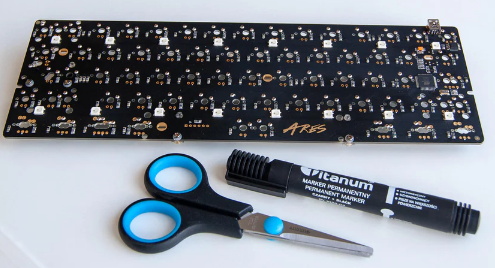

If you’re into building or modifying mechanical keyboards, you know how crucial it is to handle the PCB carefully. Whether you’re replacing switches, trimming excess leads, or modifying the layout, precision is everything. One wrong cut can ruin a board or lead to performance issues. That’s where choosing the right nipper becomes essential.

In this guide, we’ll explore the different types of nippers you can use for keyboard PCBs, their applications, and how to get the best results. By the end, you’ll know exactly which tool to pick for your next keyboard project.

Why Is the Right Nipper Important for Keyboard PCBs?

A keyboard PCB is a delicate and vital component that connects switches, diodes, and other elements. Unlike regular DIY tasks, working on a PCB requires precision and care. Using an improper tool can:

- Damage the PCB traces.

- Leave sharp edges that cause short circuits.

- Stress or crack the board, making it unusable.

This is why professionals and enthusiasts alike rely on specialized nippers. These tools are designed to cut cleanly and precisely, reducing the risk of damage and ensuring your keyboard functions perfectly.

Best Types of Nippers for Cutting PCB

1. Flush Cut Nippers: Precision at Its Best

What Nipper to Cut Keyboard PCB? Flush cut nippers are the go-to tool for most keyboard enthusiasts. They’re designed to cut leads and wires flush with the surface, leaving no protruding edges.

Key Features:

Flat cutting surface: Allows you to cut components as close as possible to the PCB.

Compact design: Easy to use in tight spaces around small components.

Best For:

Trimming component leads after soldering.

Cutting wires that connect switches to the PCB.

Removing small plastic supports or tabs.

Popular Models:

Hakko CHP-170 Micro Cutter: Known for its precision and affordability.

Xuron 170-II Micro-Shear Cutter: Offers excellent durability and a smooth cutting experience.

If your goal is a clean, professional-looking PCB with no rough edges or excess material, flush cut nippers are the best option. They’re especially useful for those who value aesthetics and functionality in their keyboard builds.

2. End Cut Nippers: Ideal for Thick Components

End cut nippers have a different design compared to flush cutters. The cutting edge is perpendicular to the handle, allowing you to cut thicker components or tabs with ease.

Key Features:

Perpendicular cutting edge: Offers better leverage and control.

Heavy-duty construction: Can handle thicker wires and components.

Best For:

Cutting PCB mounting tabs.

Trimming thicker component leads or wires.

Removing solder joints in hard-to-reach areas.

Popular Models:

Klein Tools 7280: A reliable tool for heavy-duty cutting.

IGAN-330 End Cutting Plier: Offers precision and strength for demanding tasks.

These nippers are perfect for situations where flush cutters might struggle, such as cutting through reinforced sections or thick leads. They provide more power and control, making tough cuts easier and safer.

3. Diagonal Cut Nippers: Versatility and Convenience

Diagonal cut nippers are a versatile tool that can handle a wide range of tasks. Their angled design allows you to access tight spaces while providing a clean cut.

Key Features:

Angled cutting edge: Makes it easier to reach confined areas.

Sharp blades: Ensure a clean and precise cut.

Best For:

Cutting component leads in crowded PCBs.

Trimming wires and cables.

Modifying plastic enclosures or cases.

Popular Models:

KNIPEX Diagonal Cutters: Known for their precision and durability.

Wiha Precision Diagonal Cutters: A favorite among professionals for intricate work.

If you need a versatile tool that can handle various tasks beyond just PCB work, diagonal cut nippers are a great choice. They offer a balance of precision and convenience, making them a valuable addition to any toolkit.

How to Cut a Keyboard PCB Safely?

Cutting a keyboard PCB requires more than just the right tool. Proper technique and safety precautions are equally important. Here are some tips to ensure a smooth and successful cutting process:

1. Select the Right Nipper

Choose a nipper based on the specific task. Flush cutters are ideal for precision work, while end cutters handle thicker components. Diagonal cutters are great for general-purpose use.

2. Inspect the PCB

Before making any cuts, inspect the PCB for reinforcement layers or sensitive components. Some boards have metal or thicker copper layers that require more durable tools.

3. Apply Even Pressure

When cutting, apply even pressure to avoid stressing or cracking the board. Twisting or excessive force can cause damage.

4. Cut at the Right Angle

Position the nipper at the correct angle to ensure a clean cut. For flush cutters, align the flat surface with the PCB for the best results.

5. Clean Up After Cutting

Once the cuts are made, inspect the PCB for any leftover debris or sharp edges. Use a small brush or compressed air to clean the area and ensure there are no loose particles.

Common Mistakes to Avoid

While cutting a keyboard PCB may seem straightforward, there are some common mistakes to watch out for:

1. Using the Wrong Tool

Using regular wire cutters instead of specialized nippers can lead to rough cuts and potential damage.

2. Cutting Too Close

Cutting too close to the PCB can damage traces or solder joints, leading to functionality issues. Always leave a small buffer if unsure.

3. Applying Too Much Force

Excessive force can crack the PCB or damage nearby components. Use gentle, even pressure for clean cuts.

4. Ignoring Safety Gear

Always wear safety glasses to protect your eyes from flying debris, especially when cutting thicker components.

Frequently Asked Questions

1. Can I Use Wire Cutters for PCB Work?

Wire cutters can be used in some cases, but they lack the precision of flush or diagonal cutters. For best results, use tools specifically designed for PCB work.

2. How Do I Know If My Nippers Are Dull?

Dull nippers may leave rough or uneven cuts. If you notice decreased precision or increased effort, it’s time to replace them.

3. What Is the Best Nipper for Beginners?

Flush cut nippers like the Hakko CHP-170 are affordable, easy to use, and provide excellent results, making them ideal for beginners.

4. Can Nippers Be Used for Desoldering?

Nippers can trim excess solder after desoldering but should not replace proper desoldering tools.

5. How Often Should I Replace My Nippers?

Replace nippers when they lose precision or show signs of wear, such as dull blades or misalignment.

Cutting a keyboard PCB may seem like a small task, but it can make a big difference in the final result of your keyboard build. The right nipper ensures clean cuts, preserves the integrity of the board, and enhances the overall functionality of your keyboard.

At Best Technology, we have over 18 years in the PCB cutting and PCB manufacturing. Choose us for your PCB cutting needs and experience the difference in quality and performance.

Tags: cutting pcb, pcb process, what nipper to cut keyboard pcb